Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

Enkong glass machinery manufacturer

- Enkong treats customers with sincerity and dedication and strives to provide them with excellent services.

1. The materials of Enkong glass machinery are sourced strictly according to the production plan.

2. The product is of high quality as it is manufactured under the surveillance of our highly qualified professionals.

3. Its quality is ensured by our strict QC team and management system.

4. Timely and thoughtful pre-sales and after-sales service is provided by Guangdong Enkong Machinery Co.,Ltd..

5. Advanced equipment in Enkong ensure the bulk production of glass machinery to raise the efficiency.

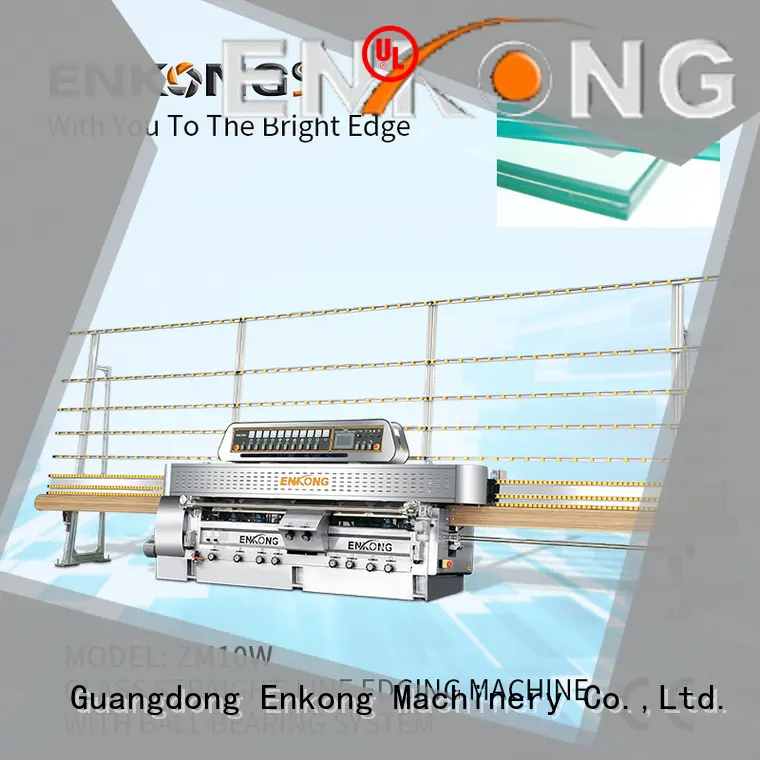

ZM10 W is suitable for processing straight-line edge & 45°arrises on glass.

A special design of the in-feed section for controlling the grinding amount of glass without adjusting each spindle individually.

Indepent wool felt wheel and the cerium water recirculation system make the flat edge more shining.

With ABB spindle motors and the conveyor system running on ball bearing units, this machine has a much stronger loading and delivering capacity, thus it is able to process mini piece and extremely thick piece with high precision and good water-proofing.

Input and output conveyors adopt timing belt which can improve the stability of transmission.

Speed is adjusted by frequency inverter; PLC with pneumatic polishing.

Technical Data

◆ Processing glass thickness: 3-25mm

◆ Angle of arris: 45°

◆ Min.size of glass: 40mm×40mm

◆ Processing speed: 0.5~5m/min

◆ Dimension: 7820×1400×2500mm

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

6 spindles for the straight-line edge (adopt the independent wool felt wheel)

2 spindles for front and back arris each.

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. Being an experienced manufacturer of glass straight line edging machine, Guangdong Enkong Machinery Co.,Ltd. has gained a good reputation for designing and manufacturing high-quality products.

2. We've developed sales abroad in recent years. Over the years of overseas development, we have won the trust and reliability of customers. This gives us great confidence to further expand global markets.

3. Guangdong Enkong Machinery Co.,Ltd. is committed to ensuring our glass machinery translate into real value for our customers. Get an offer! Through our production methods, Guangdong Enkong Machinery Co.,Ltd. aims to optimize our manufacturing mode. Get an offer! Guangdong Enkong Machinery Co.,Ltd. aims to make the global provider of glass machinery. Get an offer! Guangdong Enkong Machinery Co.,Ltd. will continue to strengthen technological innovation to enhance the overall competitive advantage in the international glass machinery industry. Get an offer!

4-19mm customized size toughened glass sheet glass making machinery

1. Brief introduction

This glass bending &tempering furnace is used for producing large-size flat, bent tempered glass for architecture, and multi-curvature bent tempered glass for automobile, shower cabins and kitchen, etc.

2. Photo of sheet glass making machinery

3. Technical Data

Below is the data for our HPQ series and we also have HPW series, HP series, HPS series, HPL series. Please advise me your requirments and we will help recommand a suit one.

Type | Max size | Min size | Thickness | Capacity | Power supply capacity(KVA) |

HPQ2515 | 2500*1500 | 150*250 | 3-19mm | 68 | ≥315 |

HPQ3015 | 3000*1500 | 150*250 | 3-19mm | 83 | ≥400 |

HPQ2518 | 2500*1800 | 150*250 | 3-19mm | 83 | ≥400 |

HPQ3018 | 3000*1800 | 150*250 | 3-19mm | 100 | ≥400 |

HPQ3618 | 3600*1800 | 150*250 | 3-19mm | 119 | ≥500 |

HPQ3021 | 3000*2100 | 150*250 | 4-19mm | 115 | ≥500 |

HPQ3621 | 3600*2100 | 150*250 | 4-19mm | 139 | ≥630 |

HPQ4221 | 4200*2100 | 150*250 | 4-19mm | 162 | ≥630 |

HPQ3624 | 3600*2400 | 150*250 | 4-19mm | 158 | ≥630 |

HPQ4224 | 4200*2400 | 150*250 | 4-19mm | 185 | ≥800 |

HPQ5024 | 5000*2400 | 150*250 | 4-19mm | 221 | ≥1000 |

HPQ6024 | 6000*2400 | 150*250 | 5-22mm | 264 | ≥1000 |

HPQ5028 | 5000*2800 | 200*300 | 5-22mm | 257 | ≥1000 |

HPQ6028 | 6000*2800 | 200*300 | 5-22mm | 308 | ≥1250 |

4. Glass Types

1) Clear float glass

2) Reflective glass

3) Low-E glass

4) Patterned glass

5) Color float glass

6) Single face silk screen glass

7) Super white pattern glass

5. Our Service

1. Free home installment and technical training, and guiding you how to operate it.

2. Offering operation parameter for processing different laminated glasses, such as tempered glass, float glass, real flower glass and picture laminated glass, etc.

6. Details show

7. Electric parts configuration

Electric parts | Brand |

Electrical system | Omron (Japan),Siemens(Optional) |

Ceramic rollers | Zhongcai(China famous brand), VSV(Optional) |

Insulated cotton | Luyang(China), ISOLITE(Optional) |

Heating wire | Cr15Ni60 |

Frequency inverter | Schneider(France),CONVO(Germany),Mitsubishi(Optional) |

8. Advantages of toughened glass machinery

a.5mm H style steel for main frame

b.3mm steel for side board

c. servo motor

d.siemens system

e.VSV ceramic roller

f. Schneider transducer

g.Aeop insulation cotton

h.ABB electrical machine

i.Cr15NI60 furnace heating wire

9. Photo of Factory

China Glass Tech Co. Ltd covers more than 60,000 square meter. Mainly engaged in glass machinery, door&windows curtain walls, glass products.

10. Certificate

11. Customer Visiting

Products have been exported to over 30 countries. Welcome your visiting.

1.Suitable for moving insulating glass /tempered glass/glass curtain wall.

2.Pneumatic glass arm is used to load and unload heavy and hot glass easily. It is easy to carry and very safe and save many labor cost.

3.It features better stability, much safer and more convenient to operate.

4.It could be used in the laminated glass production line, insulating glass production line, mirror glass production line, glass cutting and edging production line and so on.

5.With vacuum pressure charging system, equipment can ensure the whole vacuum system within a relatively constant safe pressure value during transition.

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.