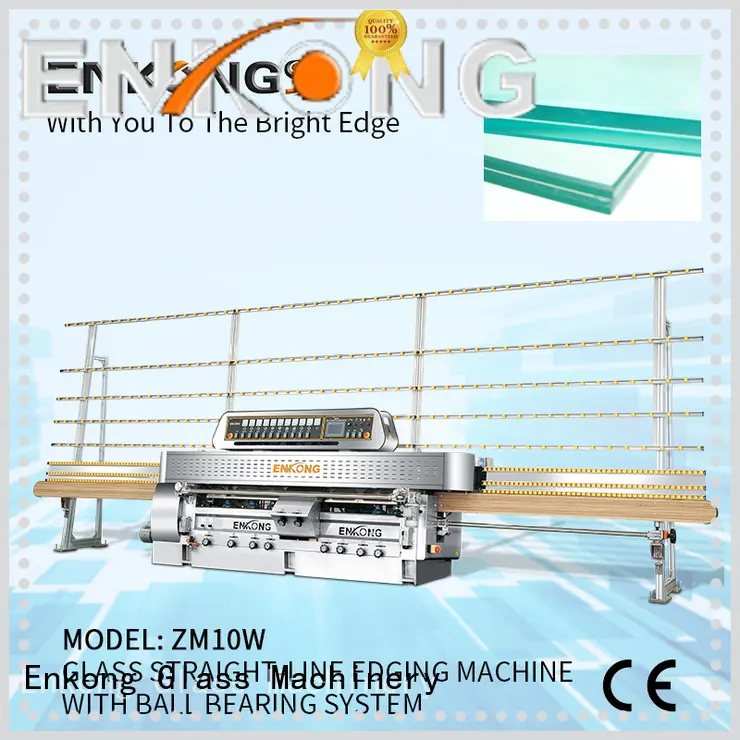

ZM10 W is suitable for processing straight-line edge & 45°arrises on glass.

Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

glass machinery zm10w manufacturer for processing glass

1. The style of glass machinery is novel and unique, thus it is suitable for glass straight line edging machine.

2. This product has great strength. It has the ability to withstand mechanical shocks from suddenly applied forces or an abrupt change in motion produced by handling, transportation or field operation.

3. The product is corrosion resistant. Its metal parts have been treated with surface paint to guard against oxidization and rust.

4. Works can get rid of jobs that are dirty dull. They will take more interest in their work and their efficiency will increase.

5. This product is totally reliable. It gives the promised output in promised time with promised efficiency. - Said one of our customers.

A special design of the in-feed section for controlling the grinding amount of glass without adjusting each spindle individually.

Indepent wool felt wheel and the cerium water recirculation system make the flat edge more shining.

With ABB spindle motors and the conveyor system running on ball bearing units, this machine has a much stronger loading and delivering capacity, thus it is able to process mini piece and extremely thick piece with high precision and good water-proofing.

Input and output conveyors adopt timing belt which can improve the stability of transmission.

Speed is adjusted by frequency inverter; PLC with pneumatic polishing.

Technical Data

◆ Processing glass thickness: 3-25mm

◆ Angle of arris: 45°

◆ Min.size of glass: 40mm×40mm

◆ Processing speed: 0.5~5m/min

◆ Dimension: 7820×1400×2500mm

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

6 spindles for the straight-line edge (adopt the independent wool felt wheel)

2 spindles for front and back arris each.

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. Since inception, Guangdong Enkong Machinery Co.,Ltd. has endeavored to manufacture high-quality glass straight line edging machine. We provide products with an outstanding performance both domestically and internationally.

2. The factory runs effectively under the guidelines of the production management system. This system, rather than focusing on mistakes after the fact, emphasizes preventive measures, which improve overall production efficiency.

3. Guangdong Enkong Machinery Co.,Ltd. is a famous company which strives to be one of the most competitive exporter in glass machinery market. Ask! Enkong Glass Machinery can provide far more value for you than other brands. Ask! The strong aim of Enkong would be to function as future global glass straight line edging machine supplier. Ask! Guangdong Enkong Machinery Co.,Ltd. constantly highlight the need for high-quality support. Ask!

Our Package Advantage:

1. Our Wooden Case is after fumigation treatment. Needn't timber inspection,saving shipping time.

2. All the spare parts of the machine were bovered by some soft materials,mainly using Pearl Wool.

Avoiding all damages that could happen in the delivery process.Then we'll covered plastic wrap out it tightly, make sure intact of the covered soft materials,also avoiding Waterproof and rust proof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has firm iron jack,convenient to Handling and transport.

Before delivery, we would do the test about 20-30 working hours for machine, and use standard packing to each configuration. We choose famous export company and transport company, making shipment more convenient and safer.

HEAD WATER JET MAKES CUTTING IS NO LONGER PROBLEM !

>>>Try to Read This -------Our Service

1. Maintenance free of charge for 12 months .

2. We will provide the consumable parts at an agency price.

3. 24 hours online service, free technical support.

4. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

5. We have manual instruction and Videos for software Installation, operation and machine's using and maintenance; We will send professional technician to customers' factory, provide them two-weeks training, including working principle of machine, Auto CAD drawing, common problems and solution, etc.

>>>Try to Read This -------FAQ

Q1: Does This Machine Pass CE Certificate?

A2: Yes, this machine passed European CE certificate and meet Safety Standard.

Q2: How much of cutting thickness?

A2: Marble is 0-120mm; granite is 0-110mm; tiles are 0-40mm; glass and mosaic is 0-80mm; steel, stainless steel, copper is 0-60mm; aluminum is 0-80mm; plastic, acrylic, foam is 0-200mm. With our double-pressures system, it can cut 0-160mm steel sheet, 0-200mm stones. It is good for customers cut thicker materials.

Q3: How fast of speed?

A3: Speed depends on cutomers' materials and cutting requirement, and customers can adjust speed parameters.

Keep safety

Although anything can be cut through, waterjet is still very safe. It is because we don't need to put any body parts under the waterjet cutting head while it is on, obviously. If there is a leak in a high-pressure water system will tend pressure rapidly drop to safe level. Water itself is safe and non-explosive and the garnet abrasive is also inert and non-toxic. So using waterjet to cut material is very safety.

Environmentally friendlyAs long as we are not machining a material that is hazardous, the spent abrasive and waste material become suitable for land fill. The garnet abrasive is inert and can be disposed of with our other trash.If we are machining lots of lead or other hazardous materials, we will still need to dispose of our waste appropriately, and recycle the water. Keep in mind, however, that very little metal is actually removed in the cutting process. This keeps the environmental impact relatively low, even if we do machine the occasional hazardous material.In most areas, excess water is simply drained to the sewer. In some areas, water treatment may be necessary prior to draining to sewer. In a few areas, a "closed loop" system that recycles the water may be required.

why choose HEAD water jet

1. Competitive price: It is can meet your budget and best-selling business very well.

2. OEM Accepted: We can produce any your request design.

3. Good Service: We treat clients as friends.

4. Good Quality: We have strict quality control system. Good reputation in the market.

5. Fast & Delivery: We have big discount from forwarder

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.