Company Advantages1. Enkong is manufactured using the best quality raw material and cutting edge technology under the guidance of skilled professionals. Our machines can be customized according to customer's requirement

2. The product, available at such a competitive price, is highly demanded by the market. All our machines are especially designed for high precision

3. Its developing requires stringent testing to ensure quality and performance. Only those that pass rigorous tests will go to the marketplace. We have perfect after-sale service for our products

4. The product complies with international quality standard and can stand any strict quality and performance test. We can provide technical support for our products

/ General description

![undefined undefined]()

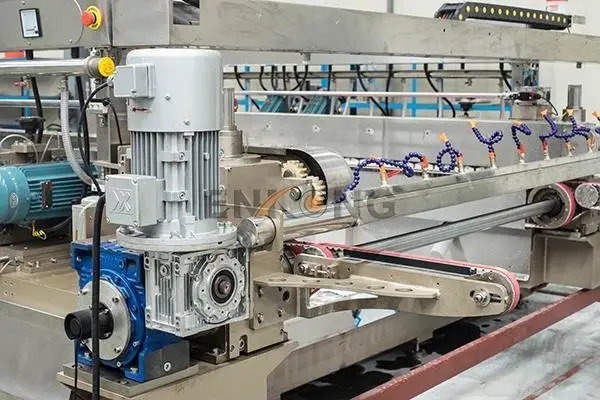

SM 20 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

/ Technical Date

Technical Date

◆ Number of Spindles: 20 (optional: 22 spindles with Low E deletion device, Extra-polish, Servo tracking Safety Corner Cutting)

◆ Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆ Dimension: 7820×1400×2500mm

◆ Width adjustment Speed: 2m/mins (optional:8m/mins)

◆ Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

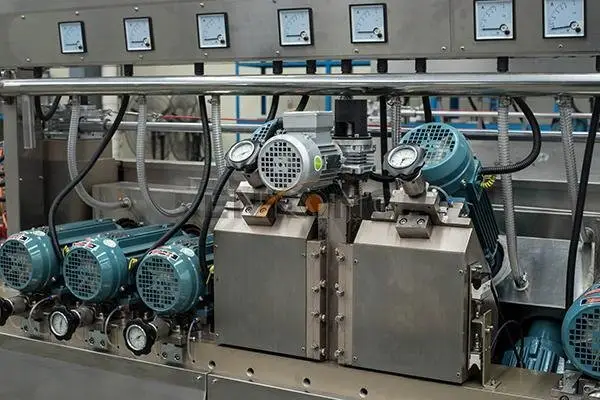

◆Total power: 68 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

/ Wheels Disposal

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features1. Guangdong Enkong Machinery Co.,Ltd. has exported its glass straight line double edging machine to many countries, including .

2. Our manufacturing and processing centers are strategically located. They are close to our customers and to growing regions, which will do a favor for our business.

3. One of the main objectives for our company is to find a balance between economic growth and cleaner environments. We will make efforts to reduce carbon footprint and energy consumption, which may also help us save production costs.