Company Advantages1. The development of Enkong concerns much electric knowledge. It is finally developed after the R&D team studied and tested electric coils, electric circuits, and inductance value. We can provide technical support for our products

2. The product has great quality light that would cause no eyestrain. People who used this product said it won't easily cause visual fatigue. Our machines are simple to install

3. The product has undergone a comprehensive quality check before shipment. The performance and operation of our products are stable

4. Through the use of advanced testing equipment in products, many quality problems can be found in time, thus effectively improving the quality of products. Our products have wide applications

/ General description

![undefined undefined]()

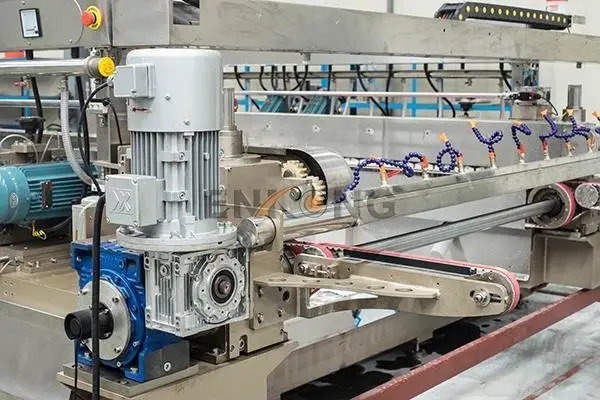

SM 20 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

/ Technical Date

Technical Date

◆ Number of Spindles: 20 (optional: 22 spindles with Low E deletion device, Extra-polish, Servo tracking Safety Corner Cutting)

◆ Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆ Dimension: 7820×1400×2500mm

◆ Width adjustment Speed: 2m/mins (optional:8m/mins)

◆ Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

◆Total power: 68 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

/ Wheels Disposal

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

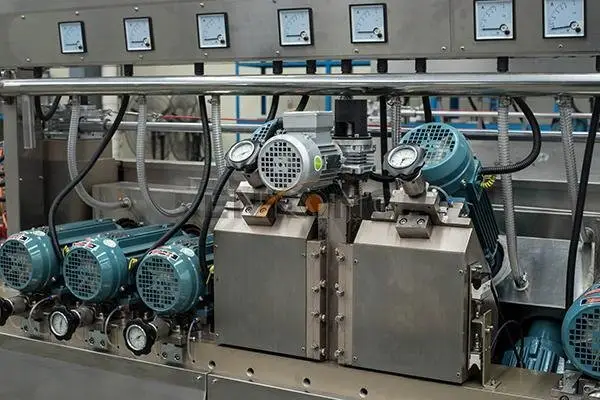

Company Features1. Guangdong Enkong Machinery Co.,Ltd. is now one of the largest-scale manufacturers, whose volume of exports has been rising steadily. Our factory has been equipped with a wide range of advanced production facilities. This gives us a powerful capacity that automates tasks, streamlines workflow, and helps us quickly define and validate the form, fit, and function of our product.

2. The factory has a group of advanced imported facilities. Produced under high-tech, these facilities contribute a lot in improving products' quality and precision, as well as the overall factory's yield and productivity.

3. Occupies a large floor area, our factory is equipped with advanced manufacturing facilities and normative production lines which can guarantee continuous and stable productivity. Our aim is to develop automatic

glass edge polishing machine with high competitiveness to be a highly trusted supplier. Get more info!