Rough grinding, fine grinding, polishing of bevel and grinding of bottom edge can be completed in one time.

Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

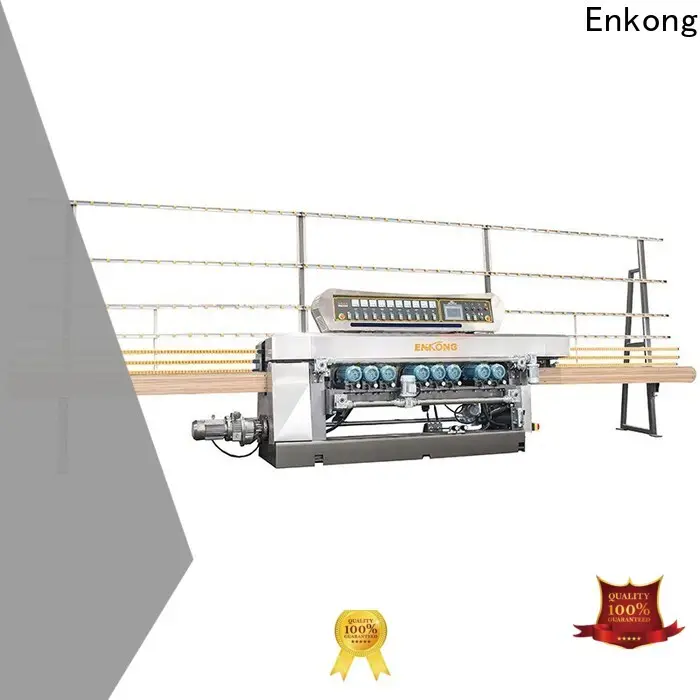

Wholesale glass beveling machine xm371 suppliers for polishing

1. The development of Enkong glass beveling machine is considered from the perspective of green design. Our machines are safe enough to operate

2. Our QC is incorporated into every stage of manufacturing process to guarantee quality for glass beveling machine . Our products are of high quality with great functions

3. The product features small friction power consumption. Due to the small contact area for the friction pair, combining with semi-fluid lubrication or boundary lubrication, the friction power is very small. English and Chinese instruction manual are available for our high quality glass machinery

4. The product stands out for its durability. Its housing features strong shock resistance to allow inner circuit boards to work well even in bad condition. All our machines are especially designed for high precision

5. The product is characterized by its corrosion resistance. It has been treated with chemical or acid-base liquid to enhance its chemical properties. Our machines feature high precision and low operating cost

XM351 is designed for grinding and polishing a bevel edge, with bottom round edger of glass with different size and thickness.

Processing thickness, angle and remaining thickness appears on digital display.

The processing speed is adjustable with a step-less motor which offers a wide range of speed selection.

Input and output conveyor adopt timing belt which can improve the transmission precision.

The grinding wheels are indirectly connected to the motor by a belt to reduce vibration.

This machine features high efficiency and precision, stable quality, easy operation and low wear.All motors using ABB brand.

Technical Date

◆ Processing glass thickness: 3-19mm

◆ Bevel angle: 3~30°

◆Bevel width: 40mm

◆ Min.size of glass: 120mm×120mm

◆Processing speed: 0.5~4.5m/min

◆ Dimension: 8250×1400×2500mm

◆ Power: 22.83KW

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

8 spindles for bevel.

1 spindles for bottom pencil edge.

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. Since its inception, Guangdong Enkong Machinery Co.,Ltd. has been recognized as a trustworthy manufacturer in China. We have been providing quality to the market.

2. We boast a high-efficient project management team. Based on their years of understanding of our industry, they work together to help us cut costs, increase productivity, improve quality, decrease lead times, and reduce waste.

3. Guangdong Enkong Machinery Co.,Ltd. pays high attention to quality and service for better development. Get price!

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.