Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

real double edger SM 22 factory direct supply for photovoltaic panel processing

1. The materials used in Enkong glass double edger are carefully selected. Only the materials that have high insulation level and strong wear resistance are adopted to guarantee stable and safe electric performance.

2. The product has good contact performance. All its parts have been professionally welded and soldered with advanced technique.

3. The product is corrosion resistant. Its metal parts have been treated with surface paint to guard against oxidization and rust.

4. The product provides people with better smelling and better tasting drinking water by reducing bacteria, heavy metal contaminants, and chlorine.

SM20 High-tech series Technical parameter(For Furniture glass)

- SM2615/25/30/40

- 3--19mm

- 250-1700/300-2700/300-3200/300-4200

- 1-15m/min

- ≤0.2mm/m

- ≤0.5mm/m

- 1-5mm

- 3mm

- 2m/min(≤ 2500mm width);4m/min(≥3000mm width)

- 1-18m/min

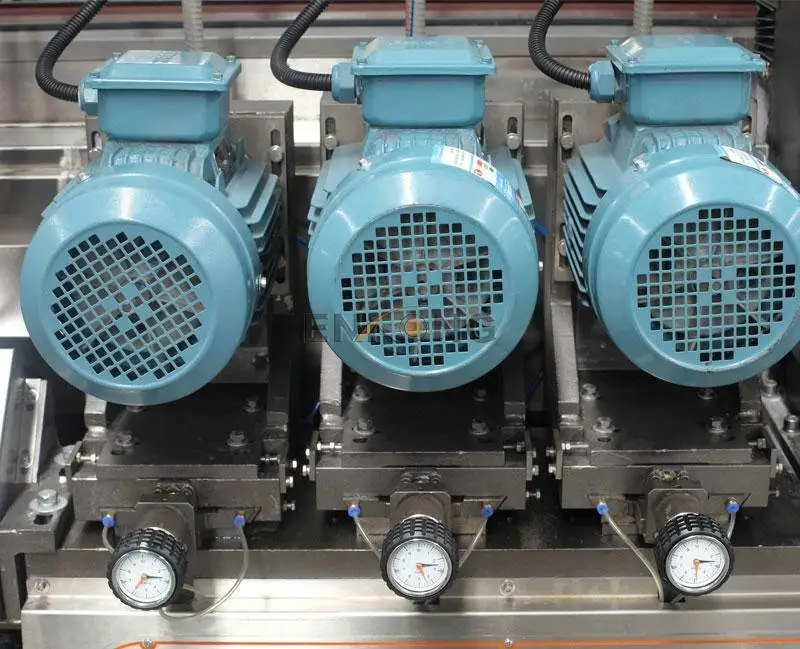

- NO.1-NO.3 using 4200rpm/min;NO.4-9 using frequency conversion;No.10-12 using 1400rpm/min.

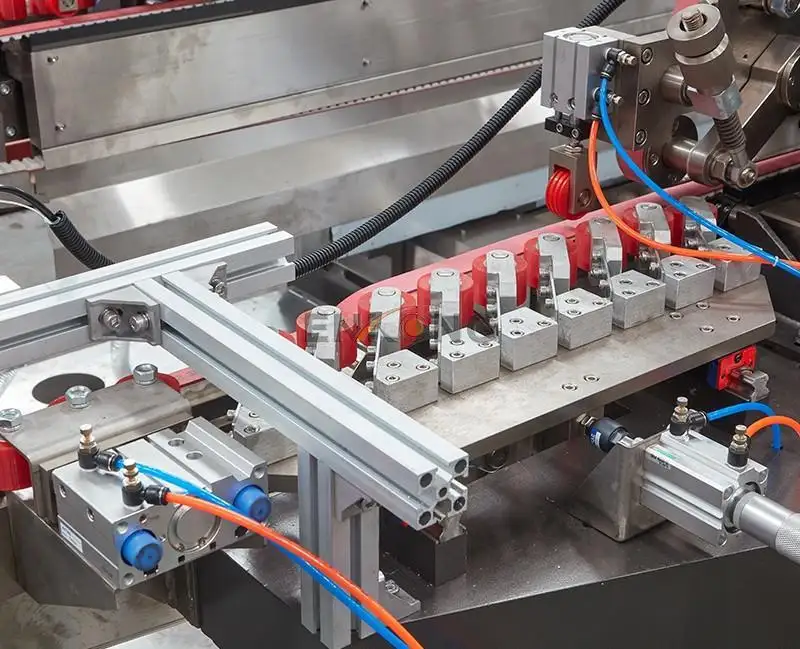

- Cylinder(Standard)/ Automatic pneumatic polishing(Option)

- About 65kw

- About 8000kgs/8500kgs/9000kgs/9500kgs

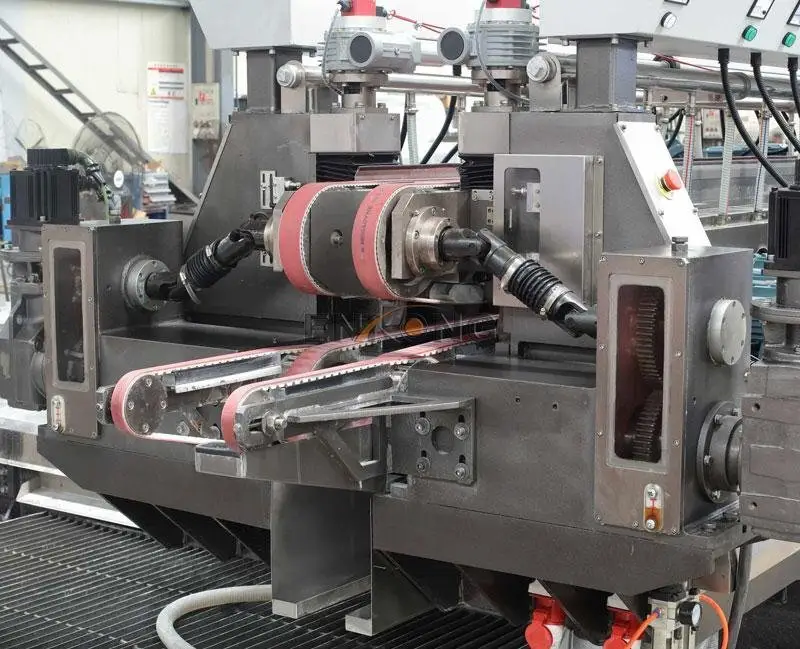

SM 26 adopted auto-polish feeding senor, optimizing polish level, secondary transmission.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

Operation Condition

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. As the leader of double edger industry, Enkong owns mature technology to produce competitive products.

2. Guangdong Enkong Machinery Co.,Ltd. has equipped appropriate advanced equipment for its factory.

3. We have been taking a visionary approach to supporting environmental progress. We’ve integrated environmental criteria into our innovation process so that every new product we launch contributes to sustainability. We are determined to become the leader in the industry and we have strong confidence to accomplish this goal. We will rely on technological innovation and cultivation of the R&D team to optimize our products and strengthen our manufacturing capabilities. We take green production as our future development direction. We will focus on seeking sustainable raw materials, clean resources, and more environmental-friendly production ways. Integrity will become the heart and soul of our company's culture. In business activities, we will never cheat our partners, suppliers, and clients no matter what. We will always work hard to realize our commitment to them.

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.