Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

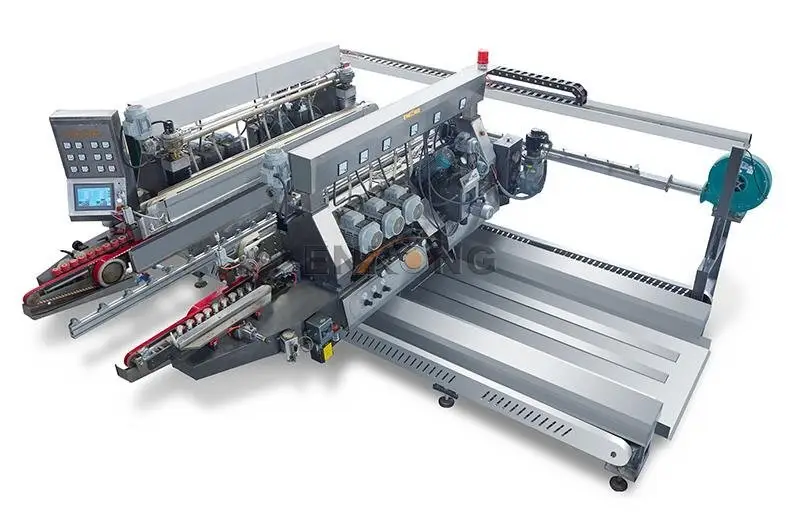

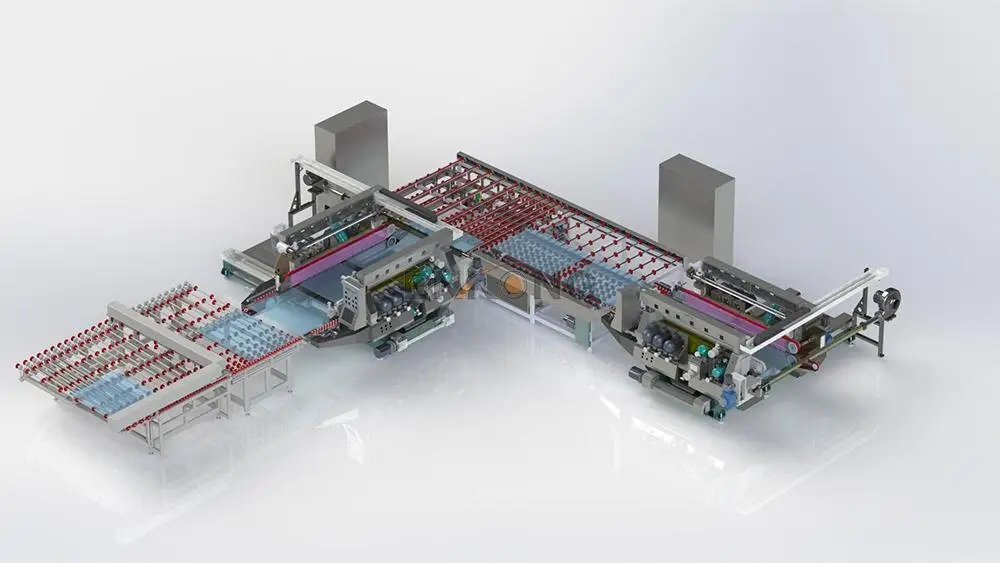

quality double edger straight-line wholesale for photovoltaic panel processing

Brand name:

Enkong

Place of origin:

Guangdong China

Certificate:

CE/ISO(CSA UL certificate can be customized according to customer requirement for the production)

Minimum order:

1 set

Price term:

FOB/CIF/C&F(optional)

Payment terms:

L/C, T/T

Package detail:

package with film

Delivery:

20-45days

/ Technical Date

SM10 Speedy Series Technical parameter(For Construction glass)

- SM1015/20/25/30/40

- 3--12mm

- 250-1700/300-2200/300-2700/300-3200/300-4200mm

- 1-25m/min

- ≤0.2mm/m

- ≤0.5mm/m

- 1-3mm

- 1.5mm

- 16m/min

- 1-25m/min

- NO.1-NO.3 using 4200rpm/min;NO.4-5 using frequency conversion;

- about 36kw

- about 5000/5500/6000/6500/7000kgs

/ General description

Production speed of 1-25m/min

Width opening speed of 16m/min

For constructoin glass

/ Operation Condition

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

TEL : (+86)757-27756688

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.

Copyright © 2025 by Guangdong Enkong Machinery Co., Ltd. |