Enterprise Strength

-

Enkong runs brand-new management and a thoughtful service system. We serve every customer attentively, so as to meet their different needs and develop a greater sense of trust.

Company Advantages1. Enkong

double glass machine is designed by our designers who are actively developing new products based on the spirit of innovation.

2. The product has an aesthetic appealing. Its delicate carving, etching, embossed pattern, or wooden texture are manually done to enhance the decor elegance.

3. The product has the advantage of energy efficiency. Its Energy Star certification indicates that this product meets strict standards of efficiency.

4. The excellent characteristics give the product greater market application potential.

/ General description

![undefined undefined]()

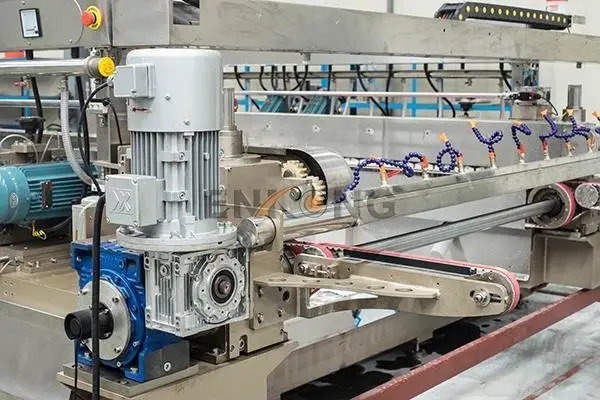

SM 20 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

/ Technical Date

Technical Date

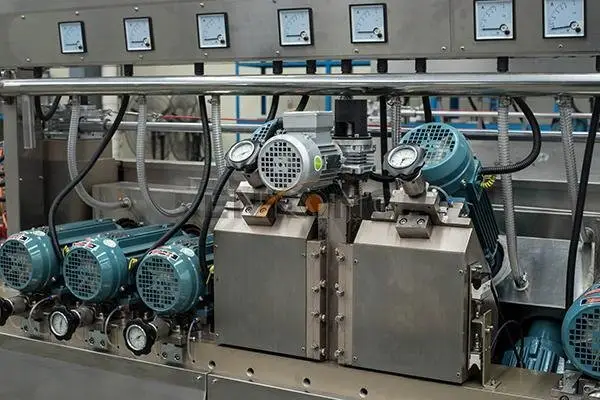

◆ Number of Spindles: 20 (optional: 22 spindles with Low E deletion device, Extra-polish, Servo tracking Safety Corner Cutting)

◆ Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆ Dimension: 7820×1400×2500mm

◆ Width adjustment Speed: 2m/mins (optional:8m/mins)

◆ Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

◆Total power: 68 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

/ Wheels Disposal

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features1. Guangdong Enkong Machinery Co.,Ltd. is a foreign owned enterprise primarily manufacturing high quality double edger machine .

2. All our

glass double edging machine have conducted strict tests.

3. We will work together to create sustainable value with everything we do – together with our employees, partners, and stakeholders. Our aim is heading Total Productive Maintenance (TPM) production approach. We endeavor to upgrade the production procedures to no breakdowns, no small stops or slow running, no defects, and no accidents. We act proactively to fight against negative environmental issues. We have set up plans and hope to reduce water pollution, gas emissions, and waste discharge. It is our firm intention to increase product quality over the entire product life cycle. So we will strive towards sustainable improvement of the product quality system and further training of our employees.