Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

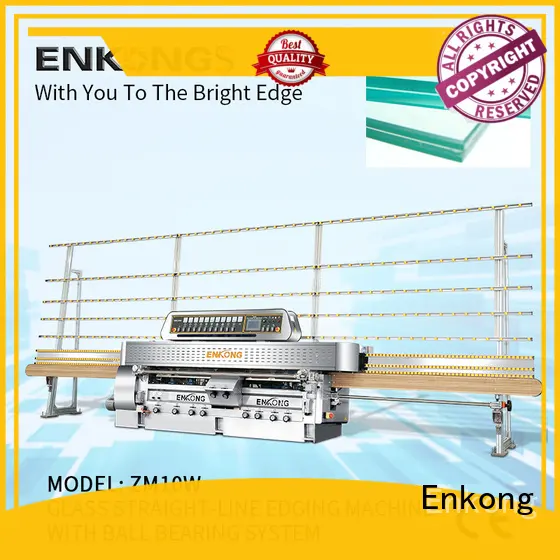

glass machinery zm10w series for processing glass

- Based on the principle of 'service is always considerate', Enkong creates an efficient, timely and mutually beneficial service environment for customers.

1. The offered Enkong glass straight line edging machine is designed by a dedicated team of experts.

2. The product features fatigue resistance. The softener or plasticizer are used to make the mobility of the molecule strengthened, thus its anti-aging ability is improved.

3. The stable and enhanced performance of this product helps to reduce the costs associated with maintenance, longer up-times, and enhanced product quality.

ZM10 W is suitable for processing straight-line edge & 45°arrises on glass.

A special design of the in-feed section for controlling the grinding amount of glass without adjusting each spindle individually.

Indepent wool felt wheel and the cerium water recirculation system make the flat edge more shining.

With ABB spindle motors and the conveyor system running on ball bearing units, this machine has a much stronger loading and delivering capacity, thus it is able to process mini piece and extremely thick piece with high precision and good water-proofing.

Input and output conveyors adopt timing belt which can improve the stability of transmission.

Speed is adjusted by frequency inverter; PLC with pneumatic polishing.

Technical Data

◆ Processing glass thickness: 3-25mm

◆ Angle of arris: 45°

◆ Min.size of glass: 40mm×40mm

◆ Processing speed: 0.5~5m/min

◆ Dimension: 7820×1400×2500mm

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

6 spindles for the straight-line edge (adopt the independent wool felt wheel)

2 spindles for front and back arris each.

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. Established years ago, Guangdong Enkong Machinery Co.,Ltd. is one of the main manufacturers of glass straight line edging machine in China with a solid industry background and related experience.

2. Guangdong Enkong Machinery Co.,Ltd. boasts technology with advanced production.

3. Enkong is always famous for its exquisite service. Check now! Enkong makes determined decisions to be the leading supplier in glass machinery industry. Check now! The goal of Enkong brand is to take the lead in the field of glass machinery. Check now!

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.