Product Comparison

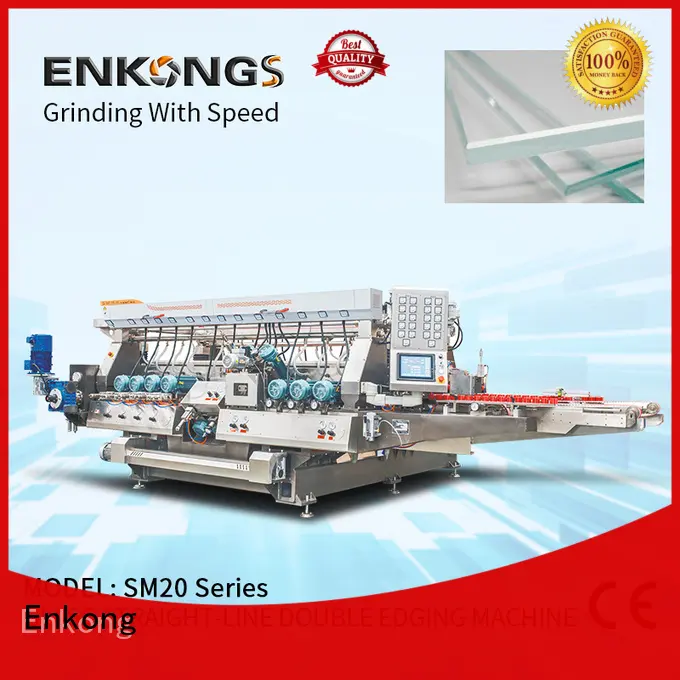

Enkong carefully selects quality raw materials. Production cost and product quality will be strictly controlled. This enables us to produce

glass edging machine which is more competitive than other products in the industry. It has advantages in internal performance, price, and quality.Enkong's glass edging machine is produced in strict accordance with standards. We make ensure that the products have more advantages over similar products in the following aspects.

Product Details

Choose Enkong's glass edging machine for the following reasons.Closely following the market trend, Enkong uses advanced production equipment and manufacturing technology to produce glass edging machine. The product receives favors from the majority of customers for the high quality and favorable price.

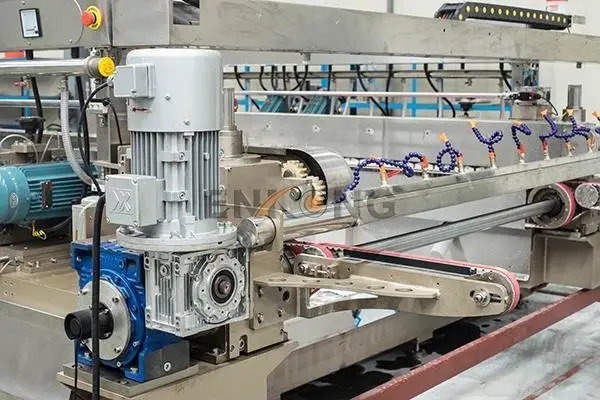

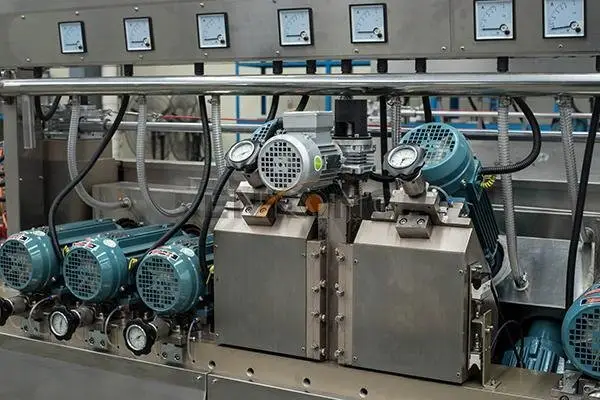

Company Advantages1. Enkong glass double edger is made of the finest quality materials which has been tested carefully before production.

2. This product is known for its system reliability. It can perform the same task endlessly in the same way without loss.

3. With rich factory experience, the quality of double edger is deeply trusted by customers.

4. The comprehensive sales network has helped Enkong to win more customers.

/ General description

![undefined undefined]()

SM 20 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

/ Technical Date

Technical Date

◆ Number of Spindles: 20 (optional: 22 spindles with Low E deletion device, Extra-polish, Servo tracking Safety Corner Cutting)

◆ Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆ Dimension: 7820×1400×2500mm

◆ Width adjustment Speed: 2m/mins (optional:8m/mins)

◆ Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

◆Total power: 68 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

/ Wheels Disposal

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features1. Enkong brand now has gained more and more attention for its rapid development.

2. The technology in Guangdong Enkong Machinery Co.,Ltd. is highly advanced and has reached the international level.

3. To achieve sustainable development, we will make all efforts to cut energy waste and conserve resources during the production processes. We have set up a green team to promote sustainable development. They research new sustainability trends and initiatives, monitor progress in production, so as to guarantee continuous and ongoing improvement in sustainability. We make efforts to contribute to communities and society. We develop locally when possible, work closely with local businesses and employ local people to promote socio-economic development.