Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

Enkong SM 10 double edger factory direct supply for round edge processing

- Enkong has a strong service network to provide one-stop service for customers.

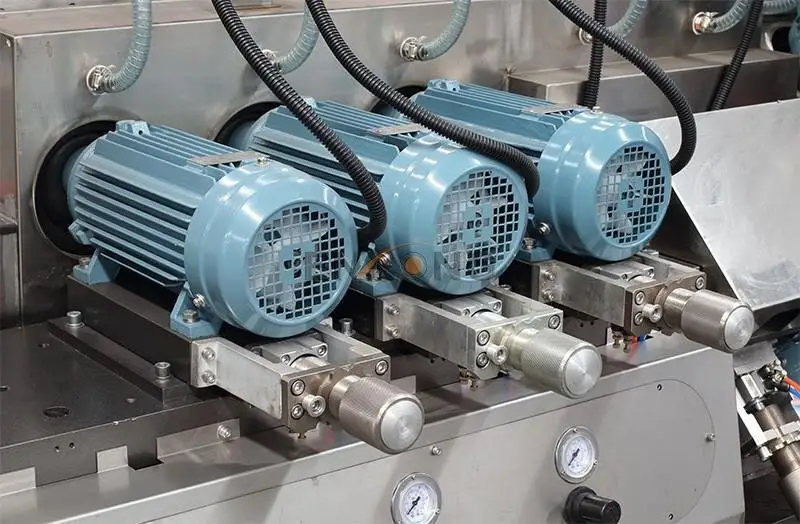

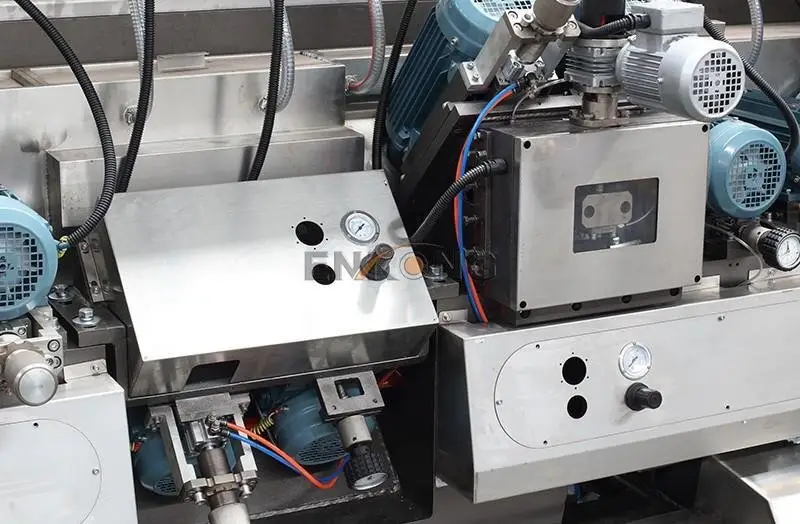

1. The production stages of Enkong double glass machine cover the following aspects. They are materials and components procurement, mechanical parts fabrication, structure fabrication, and quality tests.

2. The product poses no hazards during operation. It is designed with an auto cut-off device for overheating or overloading protection.

3. This product provides adequate strength for stacking merchandise. Numbers of tests are performed to ensure its strength and load-bearing capacity.

4. This product brings an increase in accuracy and repeatability. As it is programmed to perform a task over and over again, the accuracy and repeatability compared to an employee is far greater.

4025 L Type Glass Straight-line Double Edging Prodution Line Technical parameter

- SM2040+SJL4025+SM2025

- 3--19mm

- 4000*2500

- 12m/min

- ≤0.2mm/m

- ≤0.5mm/m

- 1-3mm

- 3mm

- 2m/min

- 15m/min

- 2800rpm and 1400rpm

- about110kw

- about23000kgs

Production speed of 1-15m/min

The automatic detects the glass length and width dimensions

Comprehensive solution setting, suitable for construction and decorative glass with variable size

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. The primary businesses of Guangdong Enkong Machinery Co.,Ltd. includes main areas of R&D and manufacturing: GLASS DOUBLE EDGING MACHINE.

2. Being qualified with the authoritative certifications, we are more confident to produce double edger with double glass machine .

3. Serving customers and contributing to the society are the business philosophy of Guangdong Enkong Machinery Co.,Ltd.. Ask online! double glass machine is a basic tenet of Guangdong Enkong Machinery Co.,Ltd.. Ask online!

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.