Application Scope

Enkong's

glass cutting machine can be used in a variety of industries.Enkong has professional engineers and technicians, so we are able to provide one-stop and comprehensive solutions for customers.

Company Advantages1. Enkong is offered in a variety of sizes, that are broken down into formats: HDTV (16:9), NTSC or Video (4:3), Widescreen PC (16:10), Square (1:1), CinemaScope (2.35:1) and various other AV formats.

2. This product has a seismic design. It is structurally stable and durable, resistant to all forms of violent vibration.

3. The product has overload protection function for its components. During the design, it is built with a thermal overload relay to guard against the damage caused by long-term overload operation.

4. Guangdong Enkong Machinery Co.,Ltd. has excellent management team, modern production lines, advanced manufacturing equipment and processes.

5. Through years of persistent development, Enkong

Glass Machinery wins good fame and recognition among double edger manufacturers.

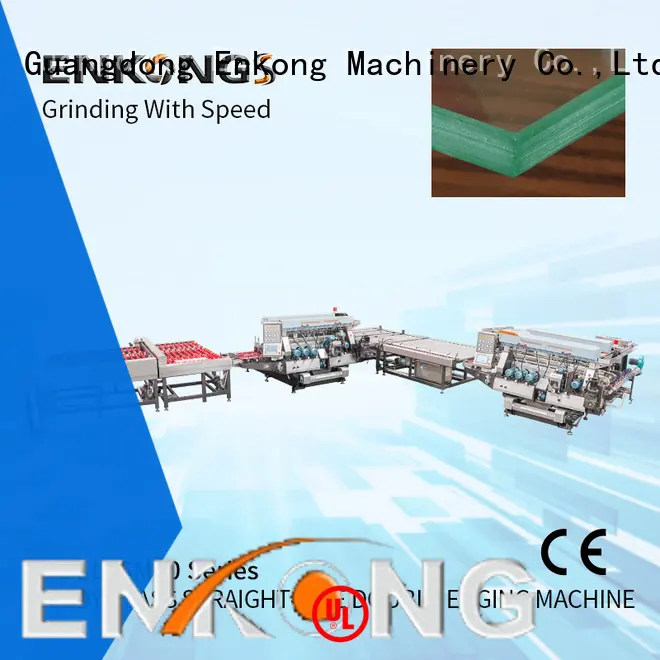

/ General description

Production speed of 1-18m/min

The automatic detects the glass length and width dimensions

Comprehensive solution setting, suitable for construction and decorative glass with variable size

![Enkong real double edger series for round edge processing1 5]()

/ Technical Date

Technical Date

◆ Number of Spindles: 10

◆ Max. glass dimension: Up to 2500

◆ Min. glass size: 300x300

◆ Glass thickness: 3~12 mm

◆ Working Speed: 0.5-18m/min

◆ Width adjustment Speed: 8m/min 16m/min

◆ Max. edge grinding: 1mm

◆ Tolerance of the diagonal(1000x1000): ±0.3mm

◆Tolerance on the parallelism(mm): ±0.1mm

◆ Total power: 35 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

Company Features1. Guangdong Enkong Machinery Co.,Ltd. leads the industry in terms of double edger production and quality.

2. The high quality double edger machine is made by high technology.

3. We are committed to a sustainable development of our Enkong brand. Please contact us! The ultimate goal of Guangdong Enkong Machinery Co.,Ltd. is to achieve continuous improvement in product quality and service. Please contact us! Guangdong Enkong Machinery Co.,Ltd. continuously optimizes the management and service systems to promote better development. Please contact us!