Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

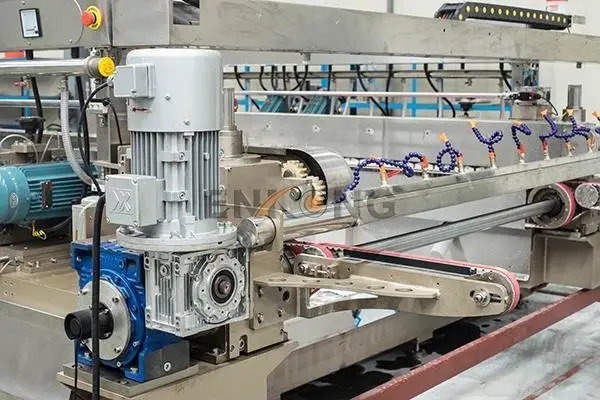

Enkong high speed double edger manufacturer for photovoltaic panel processing

1. Enkong double glass machine is designed in according to the ergonomics principle by the design team who have years of experience in creating BBQ accessories.

2. The product can work with high accuracy. Its distinguished self-diagnostic feature can make sure that every motion is of high accuracy.

3. Our quality products have a large reputation in the market.

SM 20 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

Technical Date

◆ Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆ Dimension: 7820×1400×2500mm

◆ Width adjustment Speed: 2m/mins (optional:8m/mins)

◆ Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

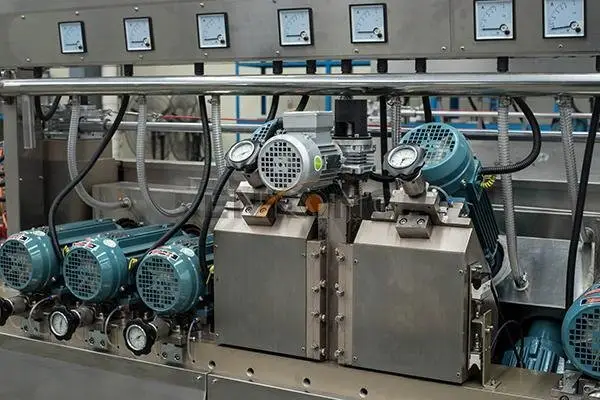

◆Total power: 68 KW

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. As one of the most accepted manufacturers of double glass machine in the industry, Guangdong Enkong Machinery Co.,Ltd. has become the preferred choice when it comes to manufacturing capacities.

2. The factory has a large scale floor space, covering a large materials storing area, machining area, testing, and packaging area. The arrangement of the space has guaranteed orderly and efficient production procedures.

3. As a product manufacturer, we always look for materials that could be given a second life, continuously upgrade our packaging methods, and reducing resources wastes to improve sustainability. Our mission is to discover new ways to rapidly deliver a full spectrum of solutions by partnering with our customers, teammates, suppliers, and communities. We attach great importance to environmental protection. We have strengthened production control and made more efficient use of materials, hoping to result in less scrap. To implement sustainability, we constantly seek new and innovative solutions to minimize the ecological impact of our products and processes during production.

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.