Application Scope

Enkong's glass machine is of excellent quality and is widely used in the Manufacturing Machinery industry.Enkong insists on providing customers with reasonable solutions according to their actual needs.

Product Comparison

glass machine has the following advantages: well-chosen materials, reasonable design, stable performance, excellent quality, and affordable price. Such a product is up to the market demand.Compared with other same kind of products in the market, Enkong's glass machine is equipped with the following outstanding advantages.

Company Advantages1. The design of Enkong

double glass machine involves several considerations, including overall bag weight, overall shape and balance, materials used in construction, and type and configuration of zippers.

2. glass double edging machine offers the benefit of superior performance and double glass machine .

3. It has been proved that glass double edging machine is reasonable in structure, double glass machine and useful in practical application.

4. By increasing productivity, cutting labor expenditure, and optimizing division of labor, the product eventually brings about profits to producers.

/ General description

![undefined undefined]()

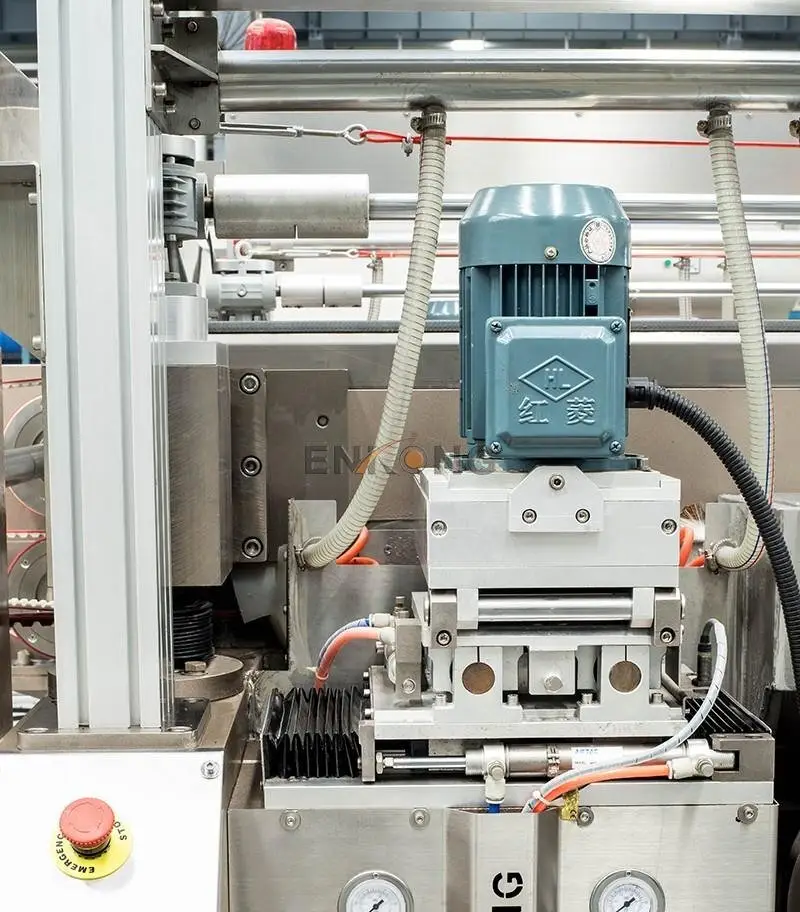

SYM12/08 double round edging machine is directed at round edge processing. Typical apply in household appliances and photovoltaic panel processing.

Modularise design

Machine body and components especial stable design for low vibration processing and ensure on precision.

/ Technical Date

Technical Date

◆ Number of Spindles: 12/08 (optional: with Low E deletion device, Servo tracking Safety Corner Cutting)

◆Max. glass dimension: Up to 2500

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Min. glass size: 150X150

◆ Glass thickness: 3~12 mm

◆Working Speed: 0.5-15m/mins

◆Width adjustment Speed: 2m/min

◆Tolerance of the diagonal(1000x1000): ±0.3mm

◆ Tolerance on the parallelism(mm): ±0.1mm

◆Total power: 24 KW

◆Weight: 6800-7800kg

![undefined undefined]()

![undefined undefined]()

Company Features1. Guangdong Enkong Machinery Co.,Ltd. has been receiving wide popularity in glass double edging machine industry since its establishment.

2. Excellent product has become a cost-effective weapon for Guangdong Enkong Machinery Co.,Ltd. to fight the market.

3. Keep being curious is our operational principle. We question, hunt, study, examine, probe, observe, query and search, hoping to learn from different perspectives. Our company is committed to sustainable manufacturing processes. All our manufacturing processes are designed with sustainability and efficiency in mind.