Company Advantages1. The design of Enkong takes into account many factors. It includes statics, dynamics, the strength of materials, vibrations, reliability, and fatigue. English and Chinese instruction manual are available for our high quality

glass machinery2. The product is now widely demanded across various industries, having an extensive applications. All of the machines have a warranty of one year

3. This product has great strength. Its parts are able to withstand various stresses caused by the load, such as thermal stresses, torsional stresses, and bending stress. We can provide technical support for our products

/ General description

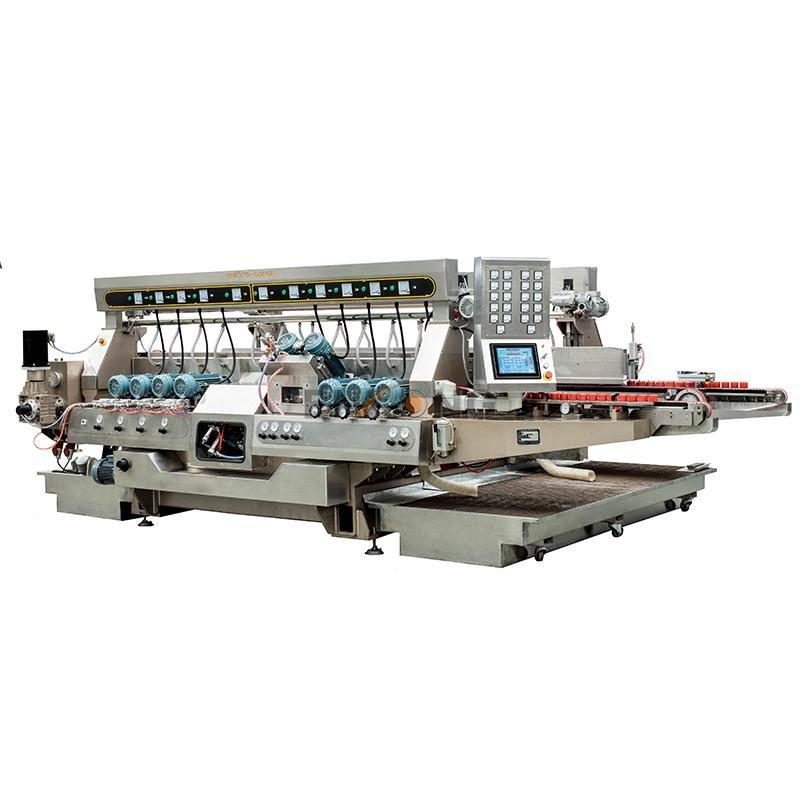

SM 22 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

/ Technical Date

Technical Date

◆ Number of Spindles: 20 (optional: 22 spindles with Low E deletion device, Extra-polish, Servo tracking Safety Corner Cutting)

◆Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆Width adjustment Speed: 2m/mins (optional:8m/mins)

◆Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

◆Total power: 68 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

![Enkong cost-effective double edger machine supplier for round edge processing 10]()

![Enkong cost-effective double edger machine supplier for round edge processing 11]()

![Enkong cost-effective double edger machine supplier for round edge processing 12]()

/ Wheels Disposal

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features1. Our company has gained many achievements and has been awarded honorary titles such as "Excellent Enterprise", "Quality Trustworthy Enterprise", "Top Ten Brands" and "Famous Chinese Brand".

2. We implement our environmental sustainability strategy by reducing our own environmental impacts such as the reduction of energy use and water.