/ General description

![undefined undefined]()

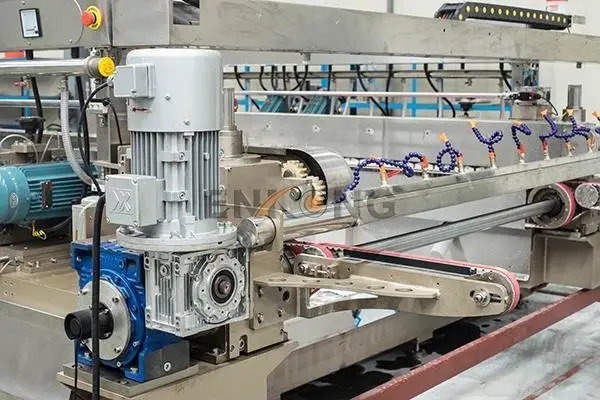

SM 20 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

/ Technical Date

Technical Date

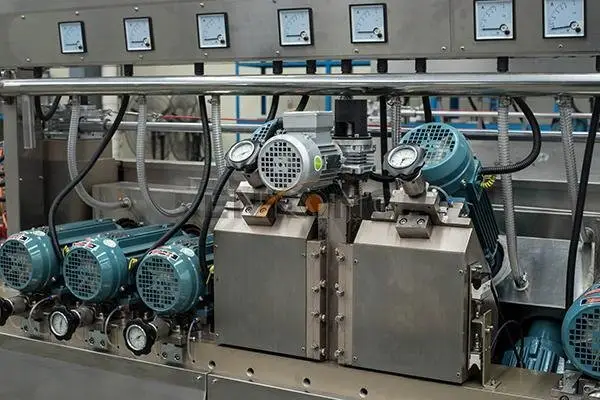

◆ Number of Spindles: 20 (optional: 22 spindles with Low E deletion device, Extra-polish, Servo tracking Safety Corner Cutting)

◆ Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆ Dimension: 7820×1400×2500mm

◆ Width adjustment Speed: 2m/mins (optional:8m/mins)

◆ Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

◆Total power: 68 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

/ Wheels Disposal

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.