Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

Enkong real glass double edging machine supplier for photovoltaic panel processing1

SM20 High-tech series Technical parameter(For Furniture glass)

- SM2615/25/30/40

- 3--19mm

- 250-1700/300-2700/300-3200/300-4200

- 1-15m/min

- ≤0.2mm/m

- ≤0.5mm/m

- 1-5mm

- 3mm

- 2m/min(≤ 2500mm width);4m/min(≥3000mm width)

- 1-18m/min

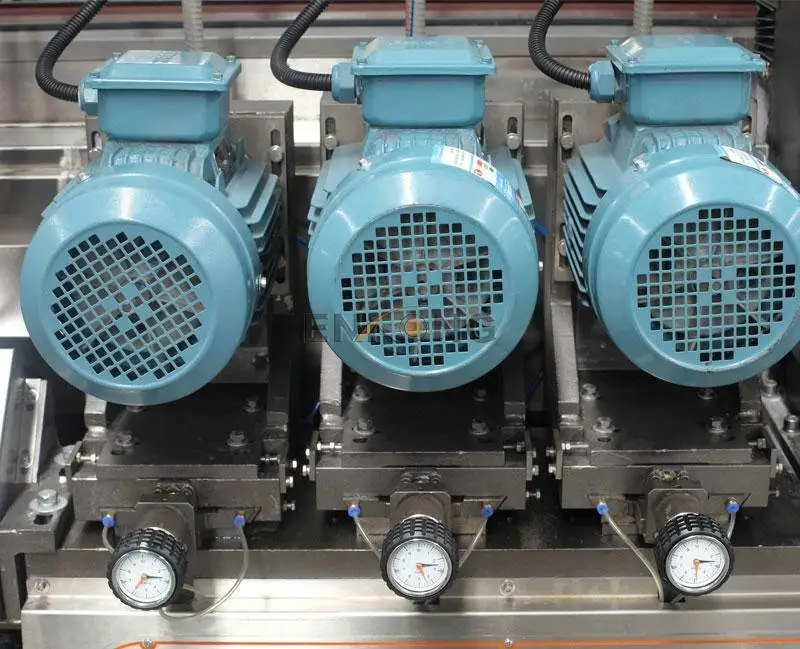

- NO.1-NO.3 using 4200rpm/min;NO.4-9 using frequency conversion;No.10-12 using 1400rpm/min.

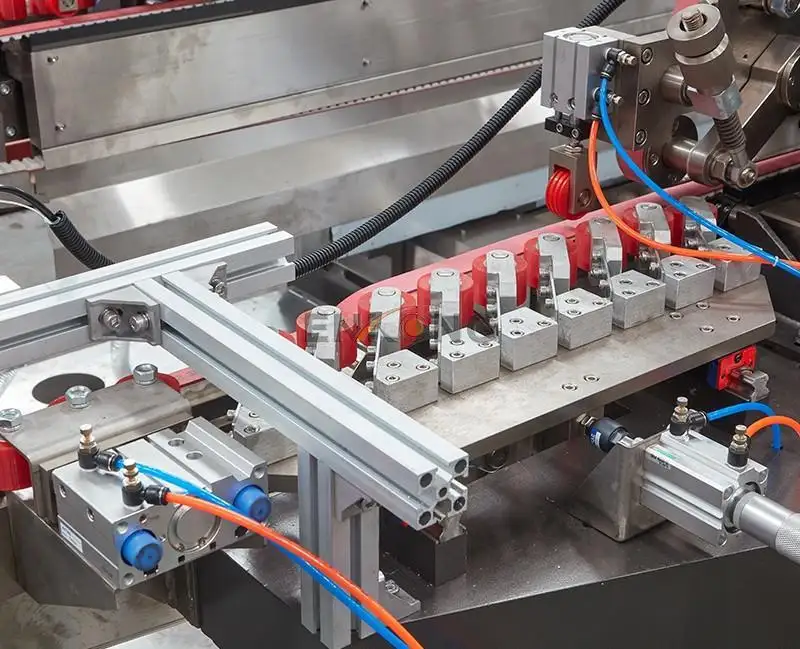

- Cylinder(Standard)/ Automatic pneumatic polishing(Option)

- About 65kw

- About 8000kgs/8500kgs/9000kgs/9500kgs

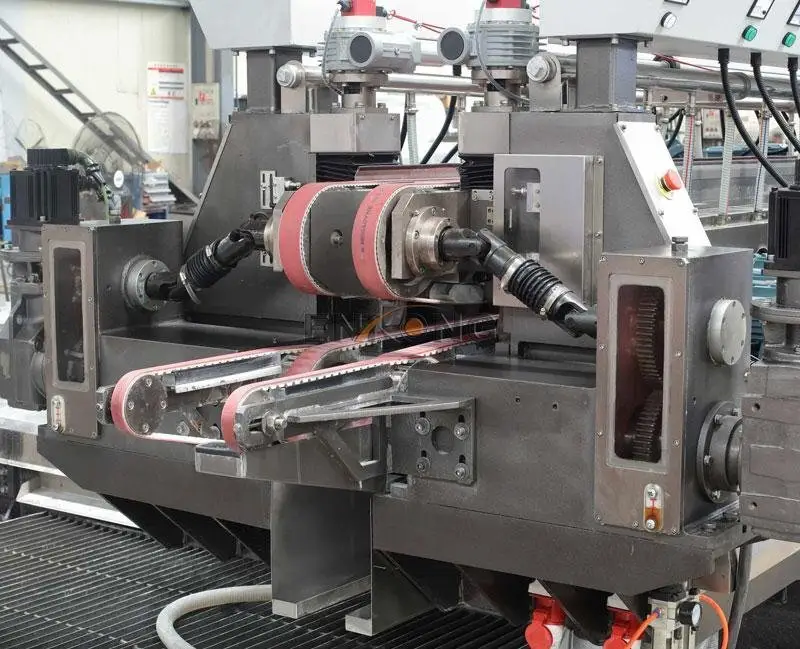

SM 26 adopted auto-polish feeding senor, optimizing polish level, secondary transmission.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

Operation Condition

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.