Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

Enkong modularise design glass double edging machine company for round edge processing

4025 L Type Glass Straight-line Double Edging Prodution Line Technical parameter

- SM2040+SJL4025+SM2025

- 3--19mm

- 4000*2500

- 12m/min

- ≤0.2mm/m

- ≤0.5mm/m

- 1-3mm

- 3mm

- 2m/min

- 15m/min

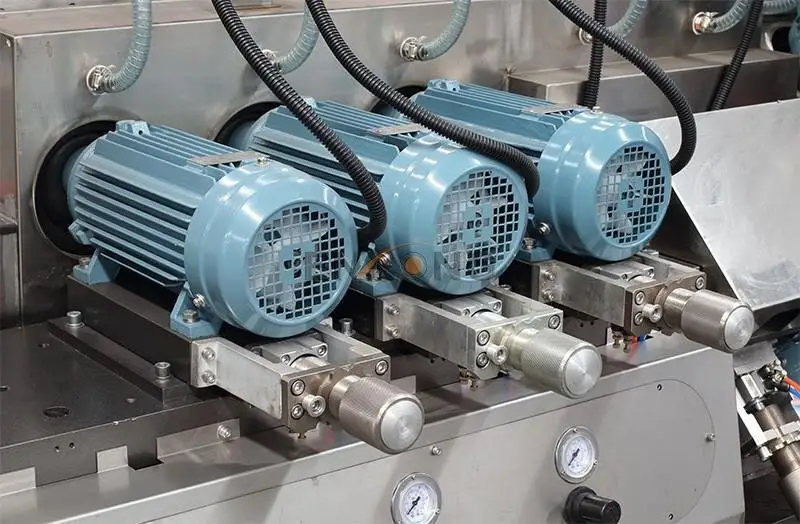

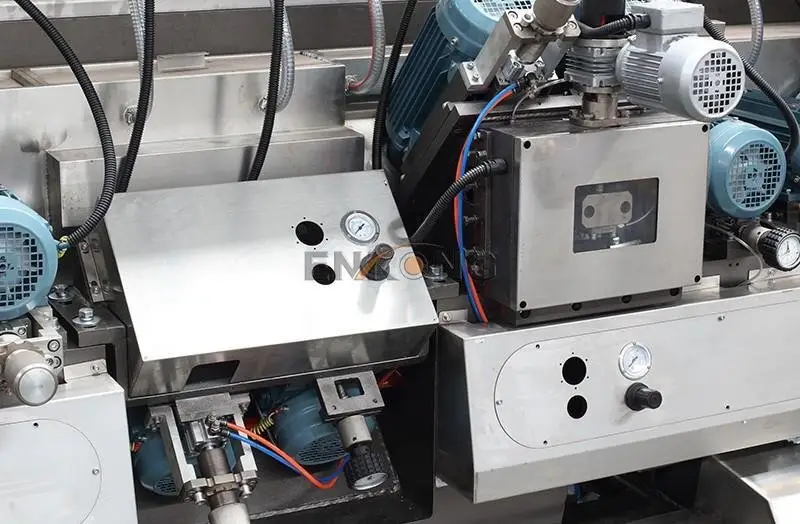

- 2800rpm and 1400rpm

- about110kw

- about23000kgs

Production speed of 1-15m/min

The automatic detects the glass length and width dimensions

Comprehensive solution setting, suitable for construction and decorative glass with variable size

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.