Application Scope

Enkong's

glass machine can play a role in various industries.Enkong has many years of industrial experience and great production capability. We are able to provide customers with quality and efficient one-stop solutions according to different needs of customers.

Company Advantages1. The production process of Enkong is regulated according to international standards.

2. Our professional technicians monitor the quality of products throughout the production process, which greatly ensures the quality of products.

3. This product is able to carry around people's stuff in an organized manner. It can easily store things which people wish to carry around while traveling.

/ General description

![undefined undefined]()

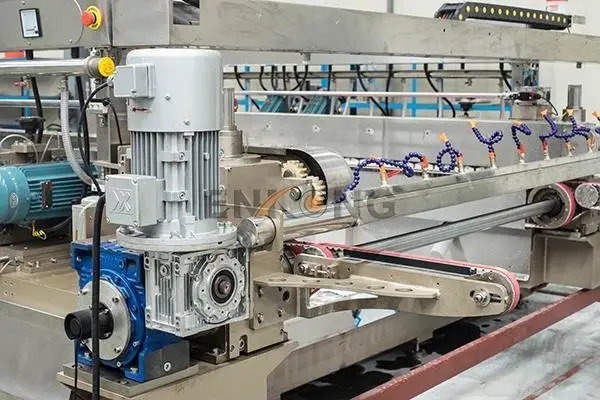

SM 20 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

/ Technical Date

Technical Date

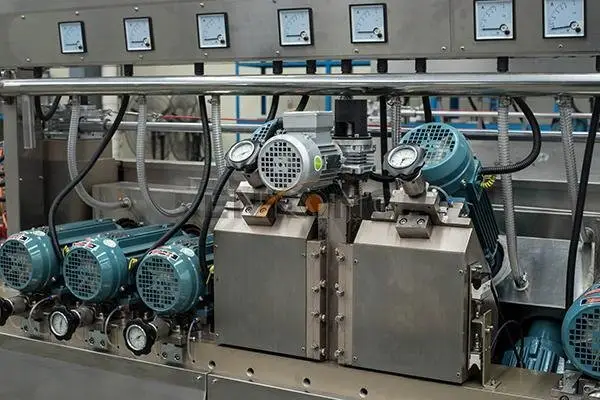

◆ Number of Spindles: 20 (optional: 22 spindles with Low E deletion device, Extra-polish, Servo tracking Safety Corner Cutting)

◆ Max. glass dimension: Up to 4200

◆ Min. glass size: 300x300 (optional: 250x250)

◆ Glass thickness: 3~25 mm

◆ Working Speed: 0.5-12 8m/mins

◆ Dimension: 7820×1400×2500mm

◆ Width adjustment Speed: 2m/mins (optional:8m/mins)

◆ Max. edge grinding: 1~3 mm

◆Tolerance of the diagonal(1000x1000): ±0.5mm

◆ Tolerance on the parallelism(mm): ±0.3mm

◆Total power: 68 KW

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

/ Wheels Disposal

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features1. Guangdong Enkong Machinery Co.,Ltd. has been admired and respected in the domestic market. We have been specialing in the R&D, manufacture, and supply of .

2. Enkong has been devoted to putting efforts into producing first-rate

glass double edging machine in the market.

3. The absolute goal of our environmental work is that our industrial processes should have the lowest possible impact on the environment. Our strategy is to stay one step ahead of official requirements by implementing an active environmental management system and to continuously improve our environmental standard. Contact us! We actively advocate the enterprise spirits of ' pragmatic and innovative'. We are committed to improving product value, optimizing the product ranges, and creating more distinctive products. We believe that our success is built on the trust we earned from clients. We work shoulder-to-shoulder with our clients to solve complex challenges in ways that minimize business risk and maximize opportunity. Contact us!