Enkong Glass Machinery specialized in making high-quality glass machine, glass edging machine for global customers.

Enkong cost-effective double edger machine factory direct supply for round edge processing

-

v s

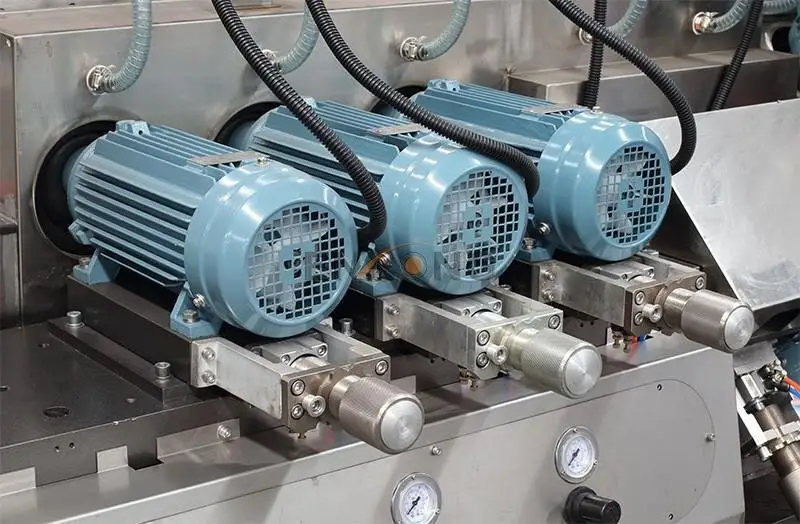

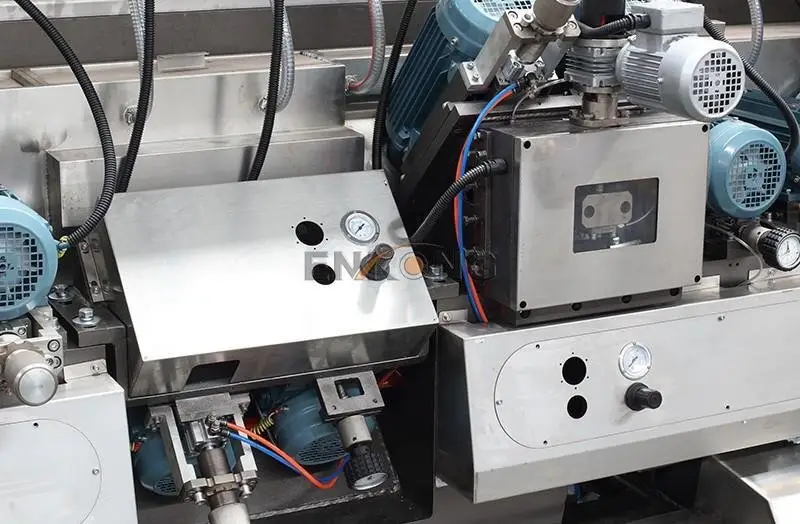

1. Enkong glass double edger is manufactured using quality raw material and comes in a variety of innovative designs.

2. The product is durable enough. Its main body is made of premium and high performance fiberglass materials and sturdy steel.

3. This product is hard yet it is typically smooth and pleasantly cool to touch. Its finish is made of high-quality ceramic glaze which is finely fired.

4. Guangdong Enkong Machinery Co.,Ltd. gets obvious price advantages.

4025 L Type Glass Straight-line Double Edging Prodution Line Technical parameter

- SM2040+SJL4025+SM2025

- 3--19mm

- 4000*2500

- 12m/min

- ≤0.2mm/m

- ≤0.5mm/m

- 1-3mm

- 3mm

- 2m/min

- 15m/min

- 2800rpm and 1400rpm

- about110kw

- about23000kgs

Production speed of 1-15m/min

The automatic detects the glass length and width dimensions

Comprehensive solution setting, suitable for construction and decorative glass with variable size

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features

1. Guangdong Enkong Machinery Co.,Ltd. is a world-renowned supplier of glass double edger .

2. Our factory has established a standardized quality management system. This quality management system enables us to achieve high-quality control in the aspects of raw materials selections, workmanship handling, automation level, and manpower control.

3. Enkong Glass Machinery will keep following the purpose of 'Think for customers, supply high quality products'. Get price! Hard it is, Enkong will still continue to move on in double edger machine industry. Get price!

As an innovator of glass machine, ENKONG will continue to pursue further development from a higher perspective, to set an example to the glass machine industry and build up an everlasting brand!

Professional glass processing machinery manufacturer and international glass equipment exporter.

CONTACT US

E-MAIL : sales@enkong.com

WHATSAPP : (+86)13724651837

OFFICE ADD :No.22, Shilong Industry Road, Lunjiao Str.,Shunde Dist., Foshan City, Guangdong, China.