Glass edging, a crucial process in the glass fabrication industry, is both an art and a science. It involves refining the edges of glass to achieve a specific finish, whether for aesthetic appeal, functionality, or safety. The glass edging process has evolved significantly over the years, with technological advancements leading to more precise and efficient methods.

edging glass

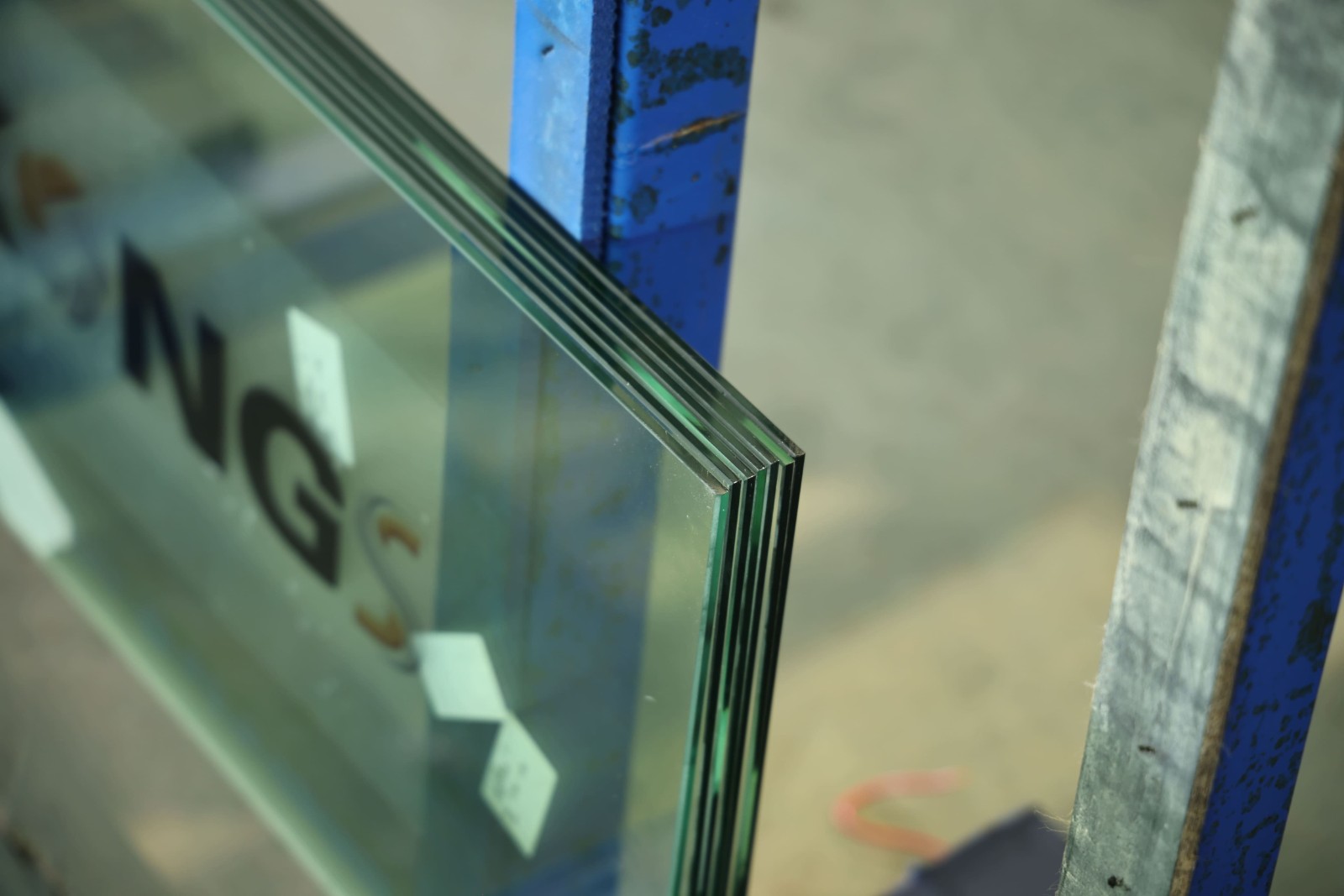

Glass edging is about shaping the edges of glass to a desired finish. This can range from simple smoothing to complex beveling or polishing. The importance of this process lies in its ability to transform a raw, potentially hazardous glass edge into a smooth, safe, and visually appealing finish. The glass edging process also plays a key role in preparing glass for further processing, such as tempering or lamination.

Glass edging feasibility and method depend on glass size. The size and thickness of the glass are crucial. With current glass edging machine technology, these proportions are limited. The minimum processable width is 30mm. This lower limit makes the glass strong enough to be edged without breaking. On the other side, the machine can process 6000mm. This limit covers several uses, from tiny homes to big industries.

The glass edging process begins with the preparation of the glass. This involves cleaning the glass and inspecting it for any defects. Once prepped, the glass is ready for edging. The process varies depending on the desired outcome but typically involves grinding the edges with abrasives.

There are several methods of glass edging, each suited to different applications. Some common methods include:

In glass edging, the cut-and-swipe method, also known as seamed edges, is a foundational technique. It utilizes a sanding belt to gently sand off the sharp edges of the glass, primarily focusing on safety rather than aesthetics. This approach ensures that the finished glass piece is safe for handling, making it particularly suitable for applications without visible or highlighted glass edges. For instance, the glass used in the frames of fireplace doors often undergoes this type of edging. The simplicity of this method, where functionality trumps form, defines its niche in the glass edging process.

Grind and chamfer, another critical technique in glass edging, involves two main steps. Firstly, the glass edges are flat ground to achieve smoothness. Following this, the top and bottom edges of the glass are carefully run along a belt, a process that eliminates sharpness and removes any chips. This results in a finished glass piece that boasts a smooth chamfer on the top and bottom, complemented by an expertly ground exterior edge. This edging type, available in straight and curved bevels, is commonly seen in frameless mirrors, including those used in medicine cabinets. The grind and chamfer method stands out for its ability to combine smoothness and aesthetic appeal in glass edging.

Pencil grind, a distinctive style within the glass edging process, employs a diamond-embedded grinding wheel to create a slightly rounded edge on the glass. This technique results in a frosty, satin, or matte finish, offering a unique textural quality. The term “pencil” in pencil grind refers to the edge radius, which mirrors the rounded shape of a pencil or a 'C'. This grind, also known as a Semi-Polished Edge, is a testament to the versatility and precision achievable in modern glass edging.

Pencil polish takes the process a step further by grinding the glass edges smoothly and finishing them with a shiny polish. This method results in a slight curve on the edge, lending the glass a sophisticated and visually appealing finish. Pencil polished edges are reminiscent of the curve of a pencil or 'C' shape, merging functional smoothness with a touch of elegance.

The flat polish method in glass edging is about achieving a sleek, modern look. This technique starts by cutting the glass edges, which are flat-polished, to create a shiny finish. Flat polish usually includes a slight 45° chamfer on the glass's top and bottom edges. This additional step is crucial for removing sharpness and mitigating "chatter," enhancing the finished piece's safety and aesthetic quality.

Glass Flat Polish

The evolution of the glass edging machine has been a game changer in the industry. These machines range from simple hand-held devices to sophisticated CNC machines. The choice of machine depends on the operation scale, the work's complexity, and the desired finish.

Modern glass edging machines offer precision and consistency, which are important in achieving high-quality results. They can be programmed to produce various edge finishes and handle different glass thicknesses and sizes. Using these machines not only improves the quality of the finished product but also enhances production efficiency and safety.

The process of glass edging is not merely a cosmetic refinement but serves several critical functional purposes, which are essential in both the manufacturing and application phases of glass products.

● Injury Prevention: Glass edging primarily aims to grind off the sharp edges and corners resulting from cutting. This is crucial to prevent injury during handling, installation, and use. The glass edging process ensures that every piece of glass is safe to handle, thereby reducing the risk of cuts or abrasions.

● Increasing Glass Strength: When glass is cut, it often results in small cracks and micro-cracks along the edges. These imperfections can lead to local stress concentration, which weakens the glass. The glass edging process grinds away these flaws, thereby increasing the overall strength of the glass. This enhancement is particularly important for glass subjected to thermal treatments or mechanical stresses.

● Reducing Breakage in Tempering: The glass edging process is important in subsequent processes like tempering. By smoothing the edges, glass edging reduces the likelihood of breakage in the tempering furnace, a crucial factor in maintaining production efficiency and product integrity.

● Geometric and Dimensional Accuracy: Post-edging, the glass needs to meet specific geometric shapes and dimensional tolerances. Glass edging ensures that these requirements are fulfilled, making the glass suitable for its intended application, whether it be in construction, automotive, or other industries.

● Quality Grading: Glass edging involves different grades of quality processing, including rough edging, fine edging, and polishing. Each stage serves a purpose, from the initial rough shaping to the final polishing, which provides a high-quality finish. This step-wise approach allows for a range of finishes tailored to the application's specific needs.

● Facilitating Glass Glazing: Finally, glass edging is often a prerequisite for glass glazing. Properly edged glass ensures a better fit and finishes in frames and supports, which is critical for both the aesthetic and functional aspects of glazing. Whether it’s for windows, doors, or decorative elements, the edging process prepares the glass for successful glazing, ensuring longevity and performance.

One of the main challenges in glass edging is managing the balance between speed and quality. High production speeds can lead to a compromise in quality while focusing too much on quality can reduce output. Addressing this challenge involves optimizing the glass edging process and selecting the right equipment.

Another challenge is the handling of different glass types and thicknesses. This requires adaptable glass edging machines and skilled operators who understand the nuances of working with various glass forms.

Lastly, probably the most prevalent of all challenges is where to get quality glass edging machines. Enkongs is one name that has been solving this issue in the glass market. With years of experience and quality equipment, you can rest assured about your glass edging machines. Contact us for more information.

ENKONG Glass Machines Manufacturer

Copyright © 2018 by Guangdong Enkong Machinery Co., Ltd. | All Rights Reserved Design by www.enkongmachinery.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.