Company Advantages1. English and Chinese instruction manual are available for our high quality

glass machinery At the same time, this glass straight line edging machine has the characteristics of . English and Chinese instruction manual are available for our high quality glass machinery

2. Before delivery, glass straight line edging machine will conduct several rounds of strict tests for quality. CE certificate is available for all our

glass processing machines3. This product is extremely resistant to corrosion. Made of heavy metal composites that have been tested by salt spray, they are not adversely affected by chemicals. Our glass machinery mainly include

Glass Edging Machine, Glass Washing Machine and Glass Drilling Machine

4. The product is durable and anti-aging. It can endure longstanding and monotonous repeated mechanical operation without failure and malfunction. Our products has high performance in glass processing

5. The product is highly wear-resistant. Its abrasion-resistant coating can provide a thin layer of lubrication to prevent parts to wear out. All our machines are especially designed for high precision

/ General description

Description

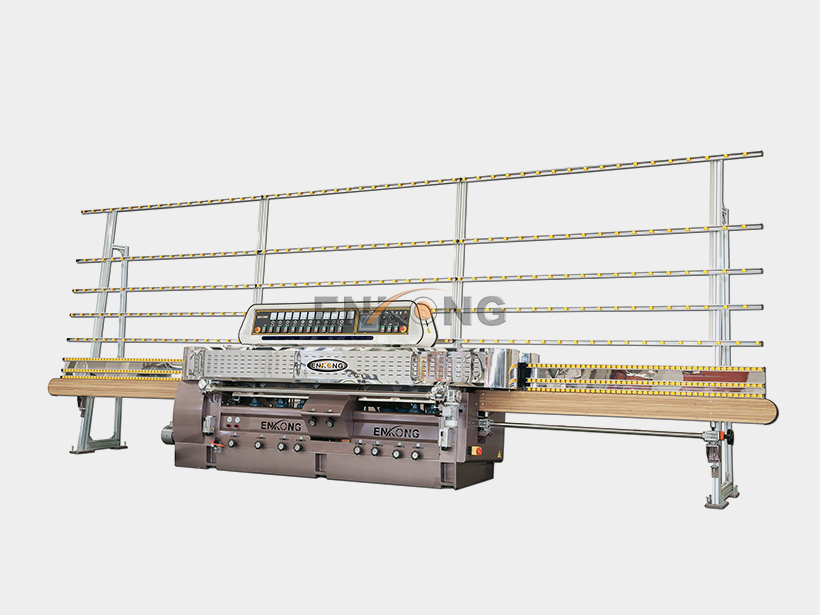

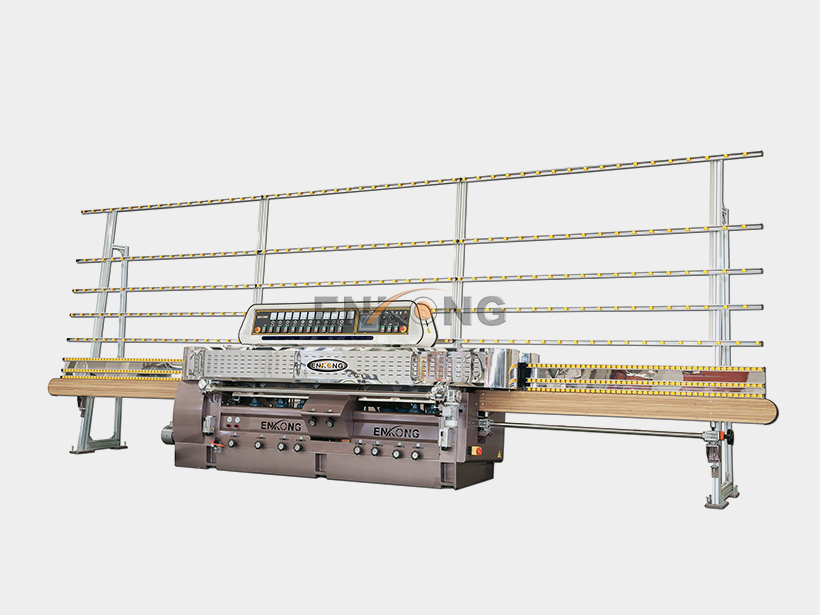

ZM10 W is suitable for processing straight-line edge & 45°arrises on glass.

Description

A special design of the in-feed section for controlling the grinding amount of glass without adjusting each spindle individually.

Description

Indepent wool felt wheel and the cerium water recirculation system make the flat edge more shining.

Description

With ABB spindle motors and the conveyor system running on ball bearing units, this machine has a much stronger loading and delivering capacity, thus it is able to process mini piece and extremely thick piece with high precision and good water-proofing.

Description

Input and output conveyors adopt timing belt which can improve the stability of transmission.

Description

Speed is adjusted by frequency inverter; PLC with pneumatic polishing.

/ Technical Date

Technical Data

◆ Spindles: 10pcs

◆ Processing glass thickness: 3-25mm

◆ Angle of arris: 45°

◆ Min.size of glass: 40mm×40mm

◆ Processing speed: 0.5~5m/min

◆ Dimension: 7820×1400×2500mm

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

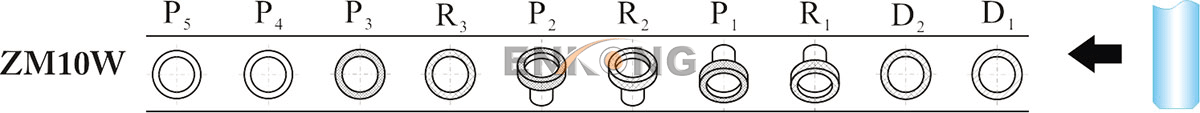

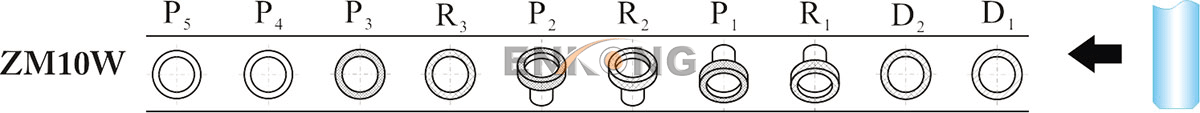

/ Wheels Disposal

6 spindles for the straight-line edge (adopt the independent wool felt wheel)

2 spindles for front and back arris each.

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features1. We have our own design team and the engineering development team. They have strong design and development capabilities and a profound understanding of the product and market trends. This makes them continuously introduced new distinctive products.

2. Providing the highest quality glass straight line edging machine has always been Enkong efforts to do. Get more info!