Company Advantages1. The development of Enkong glass straight line edging machine has adopted many high tech. They are mainly electronic information technology, automatic control theory, and microtechnology. Our glass machinery mainly include

Glass Edging Machine, Glass Washing Machine and Glass Drilling Machine

2. People who bought this product found that it almost produces no light pollution, doing no harm to people's health. The processing speed of our machines is adjustable

3. The product is long-lasting. The eco-friendly wood materials used are hand-selected and kiln-dried and is added heat and moisture to keep from cracking. Our products are of high quality with great functions

4. With a built-in filter system that is specially designed, this product generates very little radiation, including electromagnetic radiation and electromagnetic wave. Our products has high performance in glass processing

5. The product is characterized by low heat generation. During its operation, exothermic reactions between the chemicals used and Joule heating will not increase its temperature. CE certificate is available for all our

glass processing machines/ General description

Description

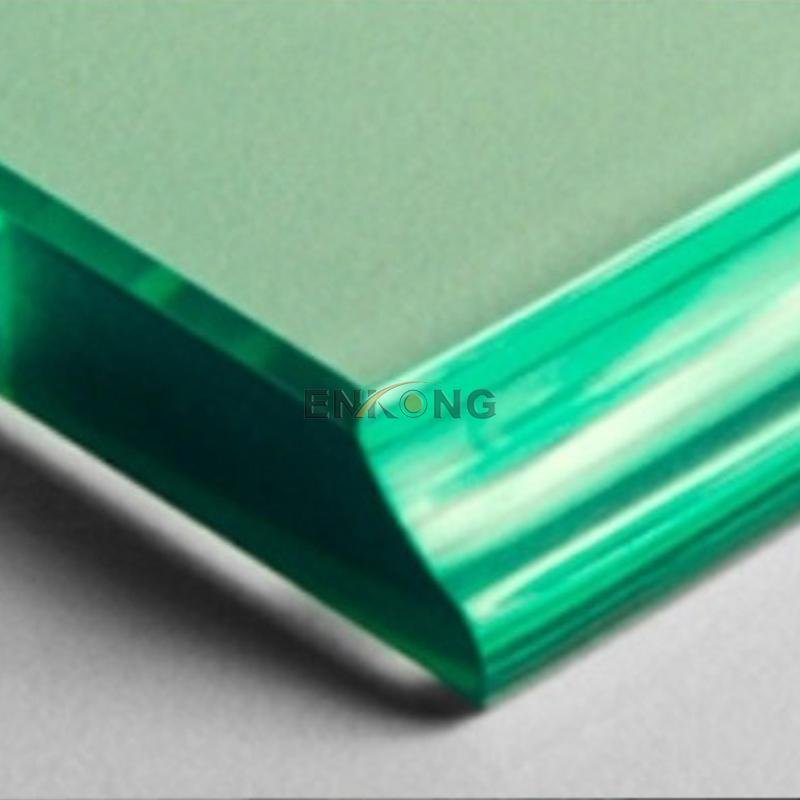

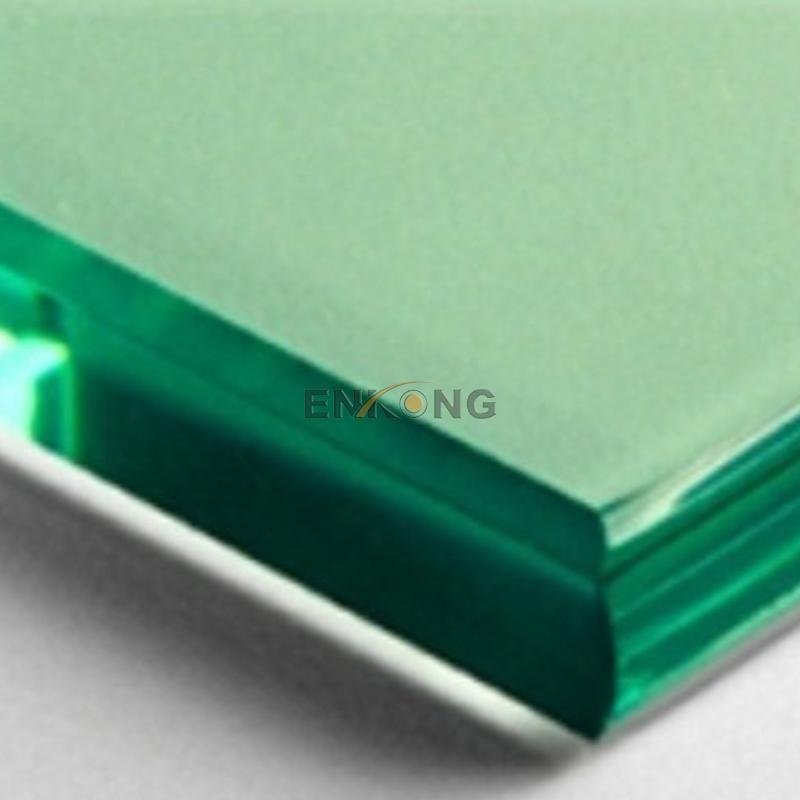

ZM4Y can process pencil/OG edging edges of different glass thickness with different shape wheels.

Description

Rough grinding, fine grinding and polishing of the pencil edge can be finished at one time.

Description

Same thickness of glass sheet can be process continually.

Description

It is suitable for rough peocessing before tempering and other further processing.

/ Technical Date

Technical Date

◆ Spindles: 4pcs

◆ Processing glass thickness: 3-19mm

◆ Min.size of glass: 80mm×80mm

◆Processing speed: 0.5~5m/min

◆ Dimension: 5800x1100×2500mm

/ producy detials

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

/ Operation Condition

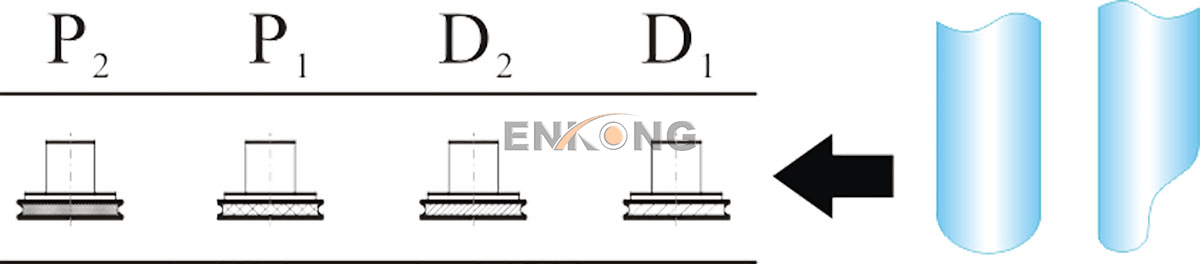

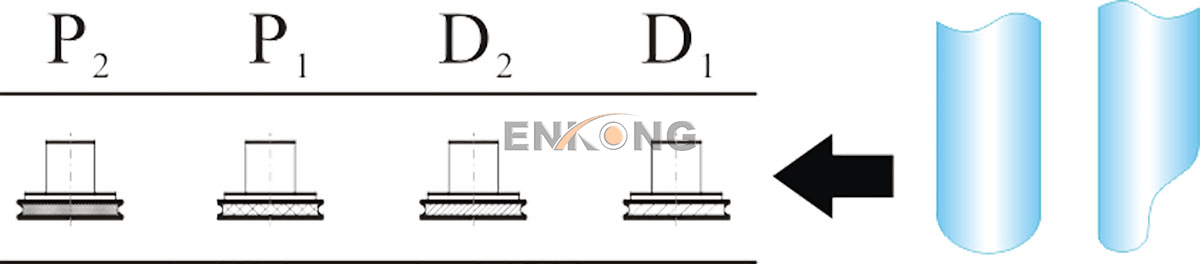

6 spindles for the straight-line edge (adopt the independent wool felt wheel)

2 spindles for front and back arris each.

/ Wheels Disposal

4 spindles for the straight-line pencil edge.

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Company Features1. Guangdong Enkong Machinery Co.,Ltd. has established a reputation for providing premium glass straight line edging machine . We are becoming one of the leading manufacturers in the industry.

2. Guangdong Enkong Machinery Co.,Ltd. is equipped with sophisticated testing and testing equipment.

3. We spare no efforts to avoid causing devastating influence on the environment, especially pollution. For instance, we only use the materials that will not contribute to environmental degradation in an effort to avoid contamination.