Related Products

SYM08 Speedy Series Technical parameter(For Photovoltaic glass )

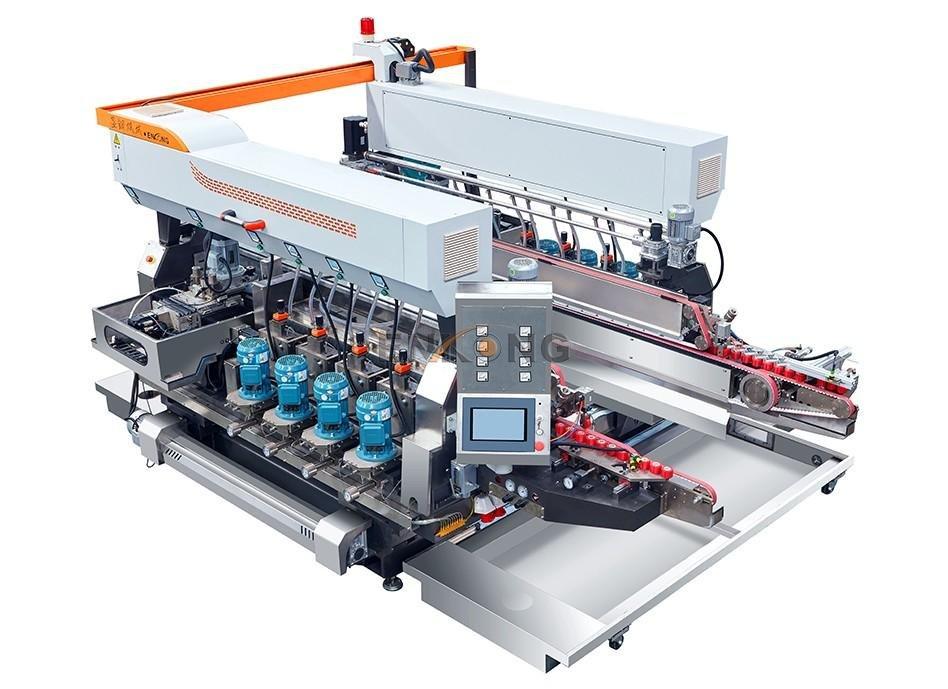

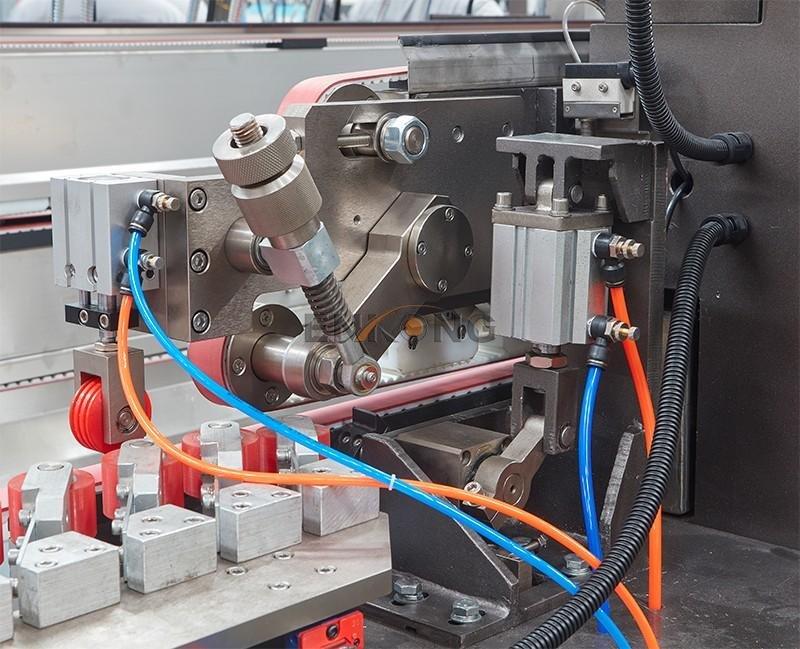

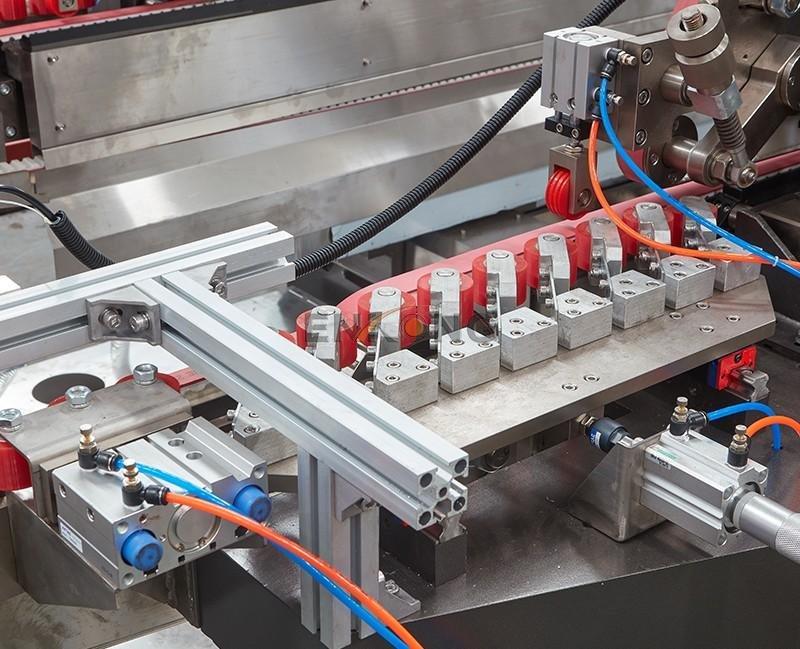

SYM12/08 double round edging machine is directed at round edge processing.

Typical apply in household appliances and photovoltaic panel processing.

Modularise design:

Machine body and components especial stable design for low vibration processing and ensure on precision.

Copyright © 2018 by Guangdong Enkong Machinery Co., Ltd. | All Rights Reserved Design by www.enkongmachinery.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.