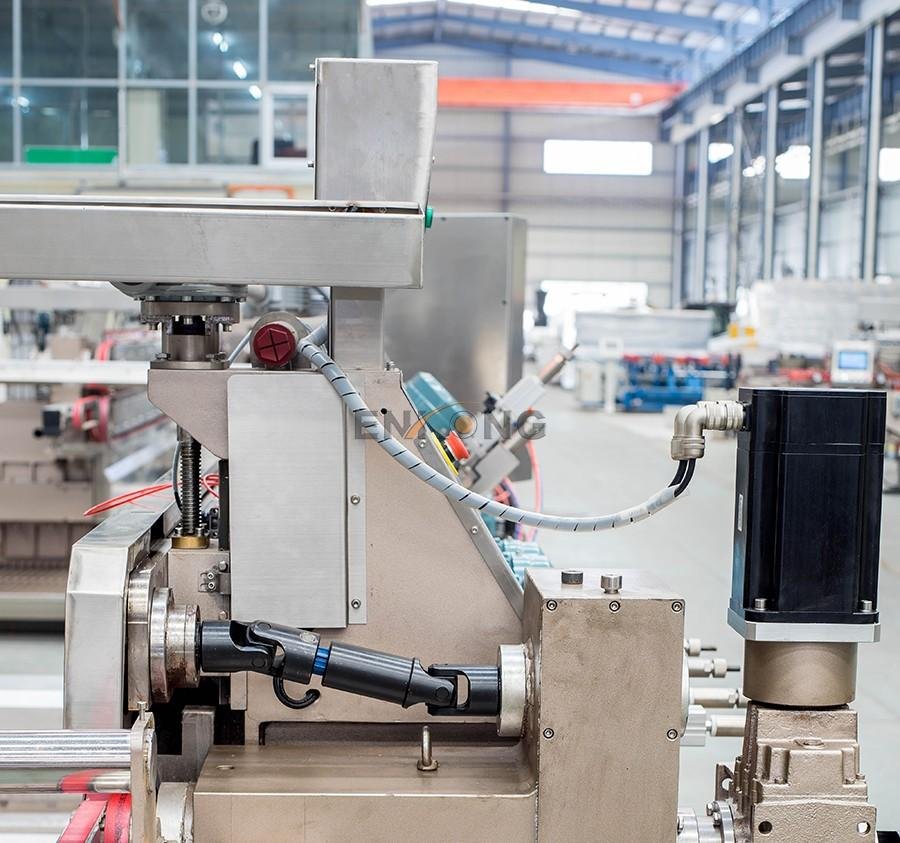

SM 22 adopted auto-polish feeding senor, optimizing polish level.

Suitable for high polish demanded products, such as household appliances and furniture.

Machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within 0.1 in 1m^2.

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Copyright © 2018 by Guangdong Enkong Machinery Co., Ltd. | All Rights Reserved Design by www.enkongmachinery.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.