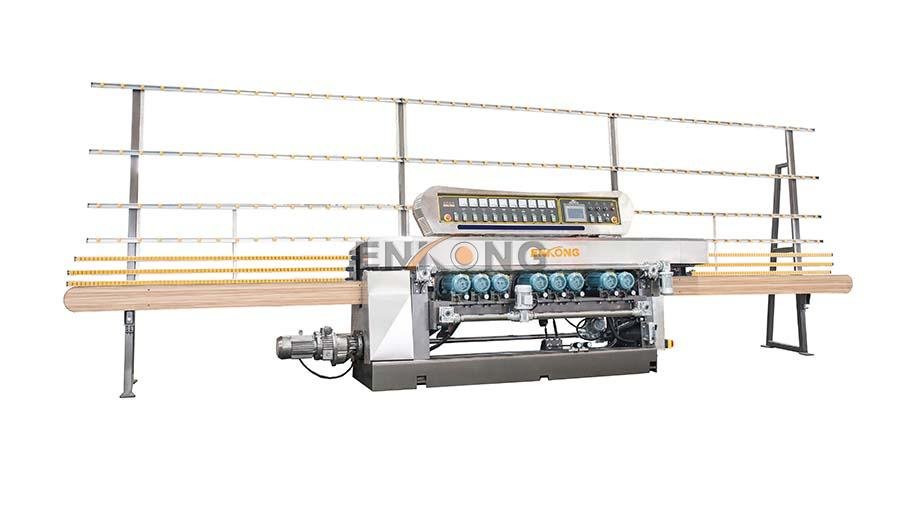

XM351 is designed for grinding and polishing a bevel edge, with bottom round edger of glass with different size and thickness.

Rough grinding, fine grinding, polishing of bevel and grinding of bottom edge can be completed in one time.

Processing thickness, angle and remaining thickness appears on digital display.

The processing speed is adjustable with a step-less motor which offers a wide range of speed selection.

Input and output conveyor adopt timing belt which can improve the transmission precision.

The grinding wheels are indirectly connected to the motor by a belt to reduce vibration.

This machine features high efficiency and precision, stable quality, easy operation and low wear.All motors using ABB brand.

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

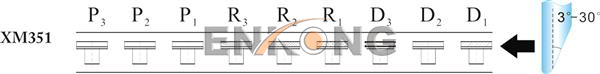

8 spindles for bevel.

1 spindles for bottom pencil edge.

★ Products order can be made according to customer’s request. Our company reserves the right to renew and revise as well as cease the technology depending on design requirements.

Copyright © 2018 by Guangdong Enkong Machinery Co., Ltd. | All Rights Reserved Design by www.enkongmachinery.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.