Related Products

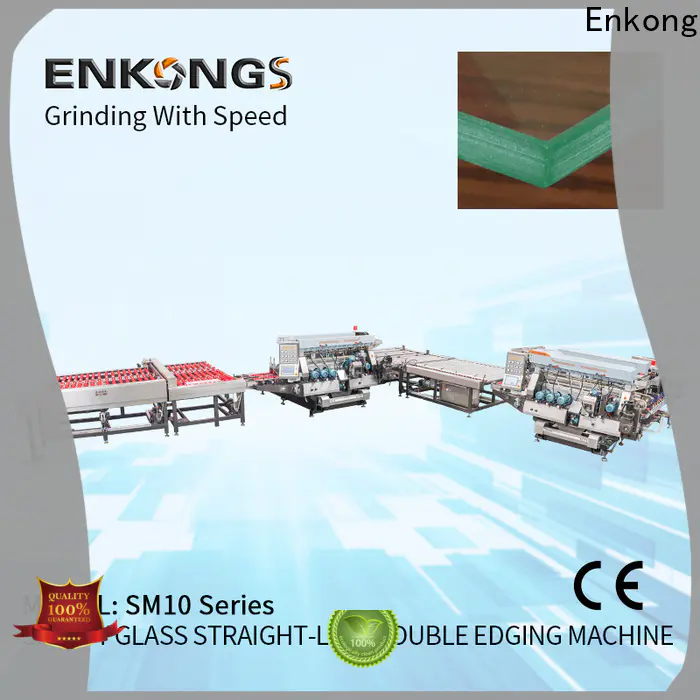

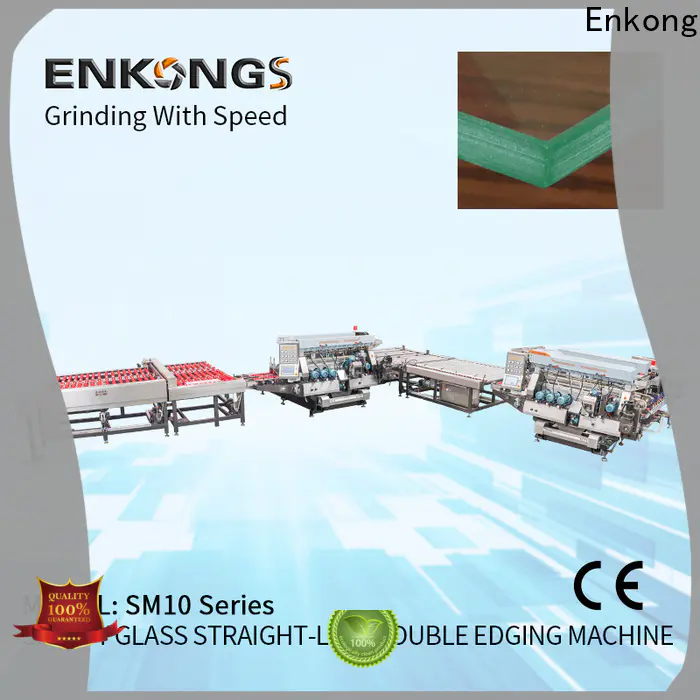

Production speed of 1-18m/min

The automatic detects the glass length and width dimensions

Comprehensive solution setting, suitable for construction and decorative glass with variable size

Power supply: AC220V, 380V, 415V ±10% 3φ 50Hz/60Hz±2%

Environment: Temperature: 1~40℃

Copyright © 2018 by Guangdong Enkong Machinery Co., Ltd. | All Rights Reserved Design by www.enkongmachinery.com

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.