Unveiling the Precision of Glass Beveling with Advanced Polishing Machines

Unveiling the Precision of Glass Beveling with Advanced Polishing Machines

Introduction:

Glass beveling is a technique used to create a decorative edge or chamfer on glass surfaces. It adds elegance and sophistication to various glass applications such as mirrors, tabletops, windows, and doors. The process requires precision and accuracy to achieve flawless results. In recent years, advanced polishing machines have revolutionized the glass industry, making beveling more efficient and precise. This article explores the benefits and intricacies of glass beveling with advanced polishing machines.

1. Understanding the Art of Glass Beveling:

Glass beveling is not just a technical process; it is an artform that requires skill and expertise. Beveled glass edges refract light, creating prismatic reflections that enhance the aesthetics of any glass object. The beveling process involves removing the sharp edges and transforming them into inclined surfaces, usually with a 45-degree angle. This intricate process adds depth, texture, and brilliance to glass, making it a popular choice for interior designers and architects.

2. Challenges Faced in Traditional Glass Beveling:

Traditional glass beveling methods required skilled craftsmen to manually grind and polish glass edges. This process was time-consuming, labor-intensive, and prone to human error. Achieving precise and consistent bevels across multiple glass pieces was a challenging task. Moreover, the inconsistencies in hand-guided tools often resulted in uneven bevel edges, decreasing the overall quality of the finished product.

3. Advancements in Polishing Machines:

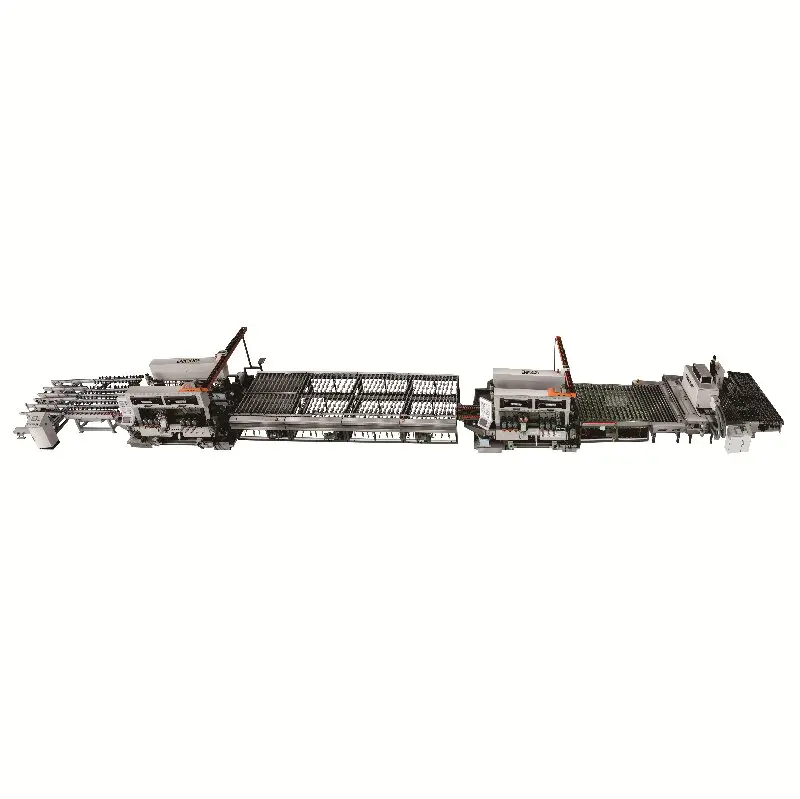

Recent advancements in technology have transformed the glass beveling process, introducing automated polishing machines. These machines utilize computer numerical control (CNC) technology to accurately shape and polish glass edges. CNC-driven polishing machines offer precise control over factors like speed, pressure, and angle, ensuring consistent bevels across numerous glass pieces. The use of advanced polishing machines has revolutionized the glass industry by increasing efficiency, productivity, and overall product quality.

4. The Precision of Advanced Polishing Machines:

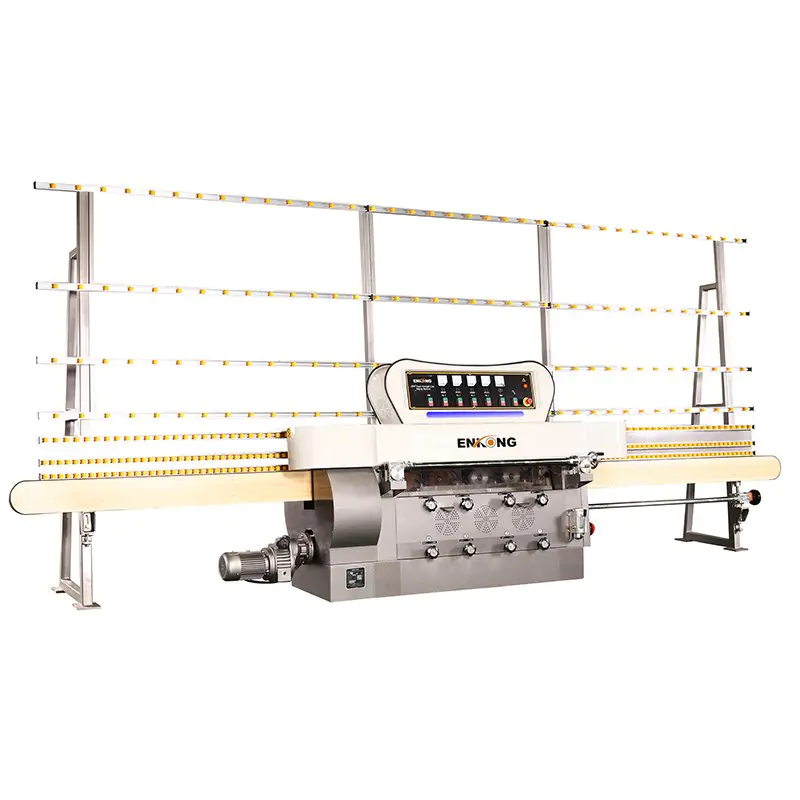

One of the key advantages of utilizing advanced polishing machines in glass beveling is the enhanced precision they offer. These machines are equipped with high-quality diamond grinding wheels that effectively remove sharp edges and create smooth, even bevels. The automated nature of the process eliminates human error, resulting in consistent and flawless beveled edges. The precision of advanced polishing machines ensures uniformity in glass dimensions, allowing for easy installation and durability.

5. Improved Efficiency and Productivity:

The introduction of advanced polishing machines has significantly improved the efficiency and productivity of glass beveling processes. These automated machines can handle high volumes of glass pieces with minimal manual intervention. The CNC technology precisely controls the movement and speed of the grinding wheels, reducing the time required for each piece. This increased efficiency allows manufacturers to meet demanding deadlines without compromising on quality, leading to higher customer satisfaction.

6. Enhanced Design Possibilities:

With advanced polishing machines, the possibilities for designing unique and intricate beveled glass pieces are endless. These machines can create a wide range of bevel widths, depths, and angles, allowing designers to experiment with different styles and patterns. From simple, straight bevels to complex, custom designs, the precision and flexibility of these machines empower designers to push the boundaries of creativity. The ability to create intricate bevels opens up opportunities in architectural designs, furniture, and decorative glass applications.

7. Quality Assurance and Durability:

Using advanced polishing machines instills confidence in manufacturers and customers regarding the quality and durability of beveled glass products. The precision afforded by these machines ensures that each glass piece meets the desired specifications, minimizing the chances of defects or inconsistencies. Additionally, the smooth, polished edges achieved through advanced beveling techniques reduce the likelihood of chipping or cracking, enhancing the overall strength and longevity of the glass.

8. Application in Various Industries:

The benefits of advanced glass beveling techniques extend beyond traditional applications. Industries such as automotive, aerospace, and home appliances are increasingly adopting beveled glass for their products. Polished glass edges offer safety advantages by reducing the risk of cuts and injuries. The aesthetic appeal and light manipulation properties of beveled glass make it a popular choice in luxury car interiors, aircraft windows, and high-end appliances.

Conclusion:

The precision and efficiency of advanced polishing machines have revolutionized the glass beveling process. These machines provide manufacturers with the ability to create flawless and uniform bevels, empowering designers to explore infinite possibilities in glass applications. The industry's transition from traditional beveling methods to automated machines has significantly improved productivity, product quality, and customer satisfaction. As technology continues to advance, the future of glass beveling looks promising, with even greater precision and innovation on the horizon.