Understanding the Importance of Glass Machines in the Construction Industry

The Importance of Glass Machines in the Construction Industry

Glass is a versatile material that adds elegance, sophistication, and functionality to modern architectural designs. It is widely used in the construction industry for its transparency, durability, and aesthetic appeal. However, transforming glass into the desired shape and size requires the use of advanced machinery. Glass machines play a crucial role in the fabrication process, enabling architects and designers to create stunning structures that enhance the visual appeal of our cities. In this article, we will explore the importance of glass machines in the construction industry and how they contribute to the development of innovative architectural designs.

Enhancing Efficiency and Precision with Glass Cutting Machines

Glass cutting machines are invaluable tools in the construction industry as they enable precise and efficient cutting of glass sheets. These machines utilize advanced technology, such as computer numerical control (CNC), to cut, score, and shape glass with great accuracy. With a glass glass cutting machine, construction professionals can create complex glass shapes, curves, and patterns that add uniqueness and charm to architectural designs.

Glass cutting machines come in various types, including automatic, semi-automatic, and manual models. Automatic machines are the most common choice in large-scale construction projects due to their ability to process large volumes of glass sheets quickly. These machines offer high-speed cutting, reducing production time and increasing overall efficiency. Semi-automatic machines, on the other hand, strike a balance between automation and manual operation, allowing operators to have greater control over the cutting process. Manual machines are suitable for small-scale operations, where precision cutting is required on a smaller scale.

Creating Intricate Designs with Glass Engraving Machines

Glass engraving machines empower architects and designers to add intricate and detailed designs to glass surfaces. These machines use a combination of cutting, etching, and engraving techniques to create stunning patterns, logos, and textures on glass. By precisely etching into the glass surface, these machines can produce custom designs that enhance the overall aesthetic appeal.

Glass engraving machines operate through a variety of methods, including sandblasting, laser engraving, and diamond bit engraving. Sandblasting involves propelling fine particles at high speeds onto the glass surface, creating a frosted or textured effect. Laser engraving, on the other hand, uses a focused laser beam to etch designs onto the glass with high precision. Diamond bit engraving utilizes specialized bits with diamond tips to physically engrave into the glass surface, allowing for intricate and detailed designs.

Supporting Structural Integrity with Glass Bending Machines

Glass bending machines are vital in the construction industry as they enable the fabrication of curved and bent glass panels that provide structural support and aesthetic appeal. These machines use a combination of heating, cooling, and pressure to shape glass sheets into various curves and angles. By utilizing precise control over temperature and pressure, glass bending machines ensure that the glass retains its strength and durability after the bending process.

Glass bending machines come in different types, including gravity bending machines, press bending machines, and CNC bending machines. Gravity bending machines utilize gravity and heat to bend glass sheets, making them suitable for simple and gentle curves. Press bending machines employ hydraulic or mechanical presses to shape glass sheets, allowing for more complex and precise bending. CNC bending machines offer the highest level of accuracy and flexibility, as they combine the functionalities of CNC control and press bending.

Streamlining Production with Glass Laminating Machines

Glass laminating machines are indispensable in the construction industry as they facilitate the creation of laminated glass, which offers enhanced safety, security, and sound insulation properties. These machines sandwich two or more layers of glass with a layer of interlayer material, such as polyvinyl butyral (PVB), and then subject them to heat and pressure. The result is a single glass unit that remains intact even if shattered, making it ideal for applications that require safety or soundproofing.

Glass laminating machines operate using either autoclave or vacuum bag pressing techniques. Autoclave machines apply pressure and heat to the glass and interlayer material in a controlled chamber, ensuring a strong bond between the layers. Vacuum bag pressing machines, on the other hand, use a vacuum bag to eliminate air and apply pressure to the glass and interlayer material. This method is commonly used for laminating small or irregularly shaped glass panels.

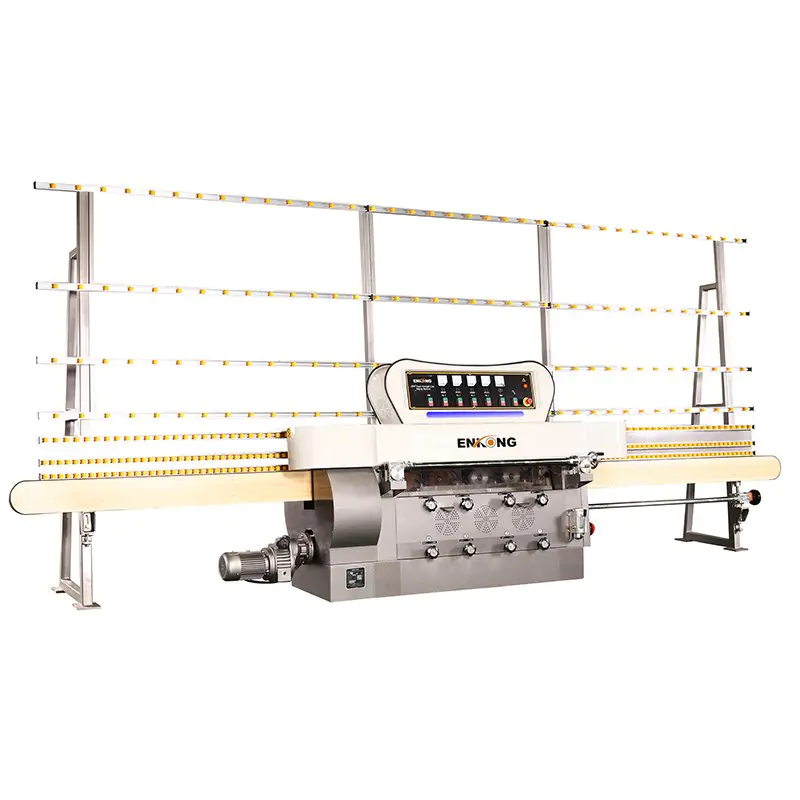

Elevating Design Possibilities with Glass Edging and Beveling Machines

Glass edging and beveling machines are crucial in the construction industry as they refine the edges of glass panels, creating smooth and polished finishes. These machines remove any imperfections, sharp edges, or uneven surfaces, enhancing both the visual appeal and safety of the glass. Additionally, glass edging and beveling machines can create decorative designs by producing angled edges or bevelling the glass surfaces.

Glass edging machines come in different configurations, including straight-line edging machines and double-edging machines. Straight-line edging machines are designed for high-volume production, as they can accurately shape and polish the edges of glass sheets in a straight line. Double-edging machines, on the other hand, operate on both sides of the glass simultaneously, saving time and increasing efficiency. These machines are ideal for glass panels that require symmetrical edging or beveling.

In Summary

Glass machines are indispensable tools for the construction industry, enabling the creation of stunning architectural designs that incorporate the beauty and functionality of glass. From cutting and engraving to bending, laminating, edging, and beveling, these machines offer precision, efficiency, and versatility in shaping glass. By harnessing the power of advanced technology, glass machines elevate design possibilities and streamline production processes, ultimately contributing to the growth and innovation of the construction industry. Architects and designers can continue to push the boundaries of architectural design, transforming cities with captivating glass structures and facades.

Nowadays, the adoption of glass machine in glass processing machines industry is quite common.

Guangdong Enkong Machinery Co.,Ltd. humbly request you to try this item in your centers and we assure you that you would be in a great pleasure with the results.

There's the area of manufacturing glass machine that's becoming very important. If you can create those things, you build this closed bond.

Guangdong Enkong Machinery Co.,Ltd. employs a group of professional staff, enhancing the function of glass machine.