The Benefits of Using a Glass Cutting and Polishing Machine in the Art Industry

Artists and craftsmen have long relied on various tools and techniques to bring their creative vision to life. One such tool that has revolutionized the art industry is the glass cutting and polishing machine. This remarkable machine allows artists to transform ordinary glass into stunning works of art with precision and ease. Whether you are a professional artist or a hobbyist, incorporating a glass cutting and polishing machine into your artistic process can offer a plethora of benefits. In this article, we will explore these advantages and discuss how this machine has become an invaluable asset to artists around the world.

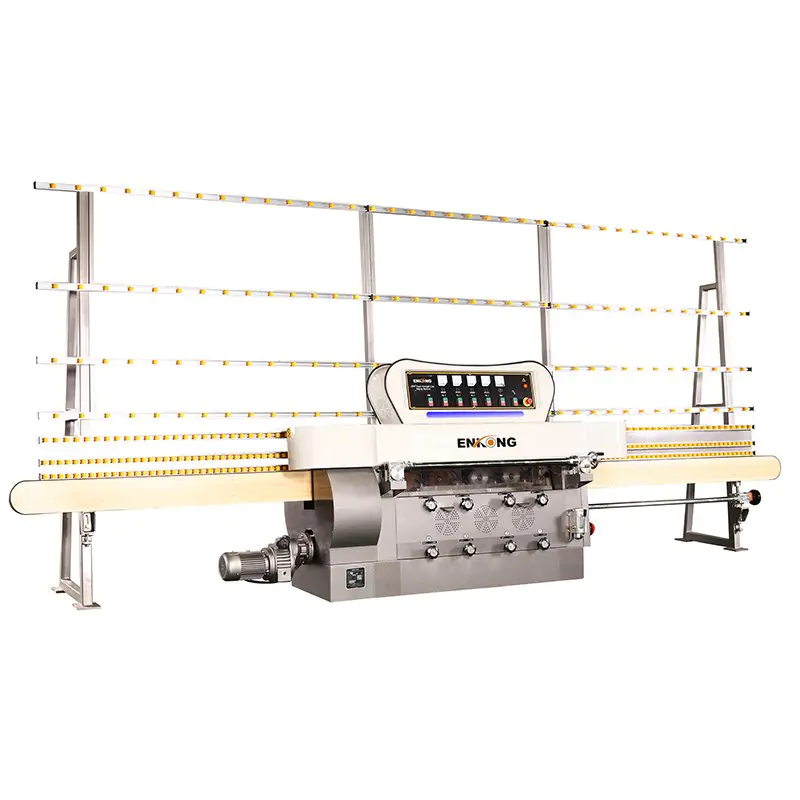

The Versatility of a Glass Cutting and Polishing Machine

Glass cutting and polishing machines offer unmatched versatility, making them an ideal addition to any artist's toolbox. With this machine, artists can create a wide range of intricate shapes and designs on glass surfaces. From straight lines to intricate curves, the possibilities are endless. Moreover, the machine allows for various types of cuts, including straight, beveled, and angled cuts.

Additionally, a glass cutting and polishing machine gives artists the ability to effortlessly polish glass edges, resulting in a smooth and professional finish. Artists can choose from different types of polishing wheels and abrasive compounds to achieve the desired level of shine and clarity. This versatility allows artists to explore different techniques and experiment with different finishes, ultimately expanding their artistic horizons.

Enhanced Precision and Accuracy

One of the main reasons why artists turn to glass cutting and polishing machines is their unparalleled precision and accuracy. These machines are equipped with advanced features such as adjustable fences, guides, and scales, making it easier than ever to make precise cuts with utmost accuracy. Artists can set specific measurements, angles, and shapes, ensuring that every cut is executed flawlessly.

Moreover, glass cutting and polishing machines often come with innovative laser alignment systems that further enhance precision. These laser guides allow artists to precisely position the glass and align it with the cutting path, ensuring a smooth and accurate cut every time. By eliminating guesswork and reducing human error, these machines empower artists to create intricate and detailed glass artworks with remarkable precision.

Time Efficiency and Productivity

In the fast-paced art industry, time efficiency is crucial. Glass cutting and polishing machines excel in this aspect, allowing artists to save significant time and streamline their workflow. With the ability to execute precise cuts quickly and effortlessly, artists can complete their projects in a fraction of the time it would take with traditional manual methods.

Furthermore, these machines often come equipped with advanced automation features, such as programmable cutting paths and automatic polishing cycles. Artists can input their desired specifications into the machine's control panel, and it will execute the entire process automatically. This automation not only saves time but also boosts productivity by allowing artists to work on multiple projects simultaneously.

Improved Safety and Ergonomics

Working with glass can be hazardous, particularly when cutting and polishing it manually. Glass cutting and polishing machines address this concern by offering improved safety features, ensuring the protection of artists and craftsmen. These machines are designed with safety shields and guards that prevent accidental contact with sharp cutting blades and abrasive wheels, reducing the risk of injuries.

Additionally, glass cutting and polishing machines promote better ergonomics in the artistic process. Traditional manual methods require artists to exert significant physical effort when cutting and polishing glass. This repetitive motion can lead to fatigue and discomfort over time. However, with a glass cutting and polishing machine, artists can rely on the machine's mechanical power, reducing physical strain and allowing them to work on their projects for longer periods without discomfort.

Cost Savings and Longevity

While glass cutting and polishing machines require an initial investment, they offer long-term cost savings for artists in the art industry. Purchasing pre-cut glass or outsourcing cutting and polishing services can be expensive in the long run. With a glass cutting and polishing machine, artists have the freedom to source their own glass sheets and create custom designs without relying on external services. This independence not only reduces costs but also provides artists with creative flexibility.

Furthermore, glass cutting and polishing machines are built to last. With proper maintenance and care, these machines can provide artists with years of reliable service. This longevity ensures that artists can continuously explore their creativity without the worry of frequent repairs or replacements, making them a sound investment for professionals and enthusiasts alike.

In conclusion, a glass cutting and polishing machine is an invaluable tool in the art industry. Its versatility, precision, time efficiency, safety features, and long-term cost savings make it an indispensable asset for artists and craftsmen worldwide. Whether you are creating stained glass windows, glass sculptures, or intricate glass jewelry, incorporating a glass cutting and polishing machine into your artistic process will undoubtedly elevate your creations to new levels of beauty and sophistication. Embrace the power of this remarkable machine and unlock your artistic potential today.