The Applications and Benefits of Glass Edge Polishing Machines in Glassblowing

The Art of Glassblowing: A Brief Overview

Glassblowing is a centuries-old technique that involves shaping molten glass into various objects, such as vases, sculptures, and decorative items. This intricate craft requires immense skill, precision, and attention to detail. While traditional glassblowing methods have their charm, the use of modern technology has revolutionized the process. Glass edge polishing machines, in particular, play a crucial role in enhancing the quality and aesthetics of glassblown products. In this article, we will delve deeper into the applications and benefits of these machines in the art of glassblowing.

Enhancing Precision and Uniformity

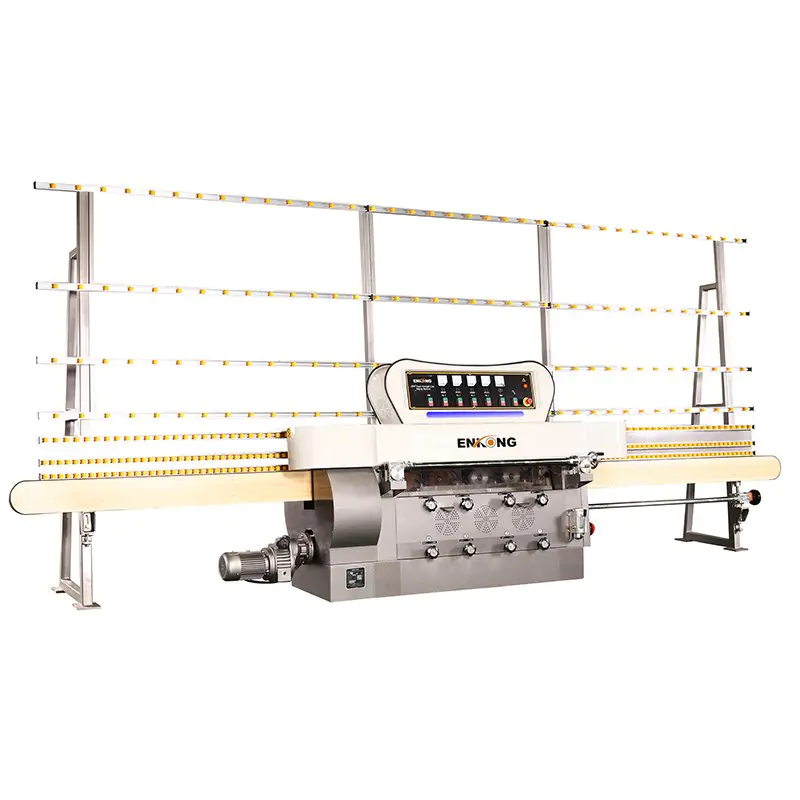

Glass edge polishing machines are designed to refine the edges of glass objects, ensuring a smooth and polished finish. For glassblowers, precision is of utmost importance, as any imperfections or rough edges can compromise the overall quality of the final product. These machines provide a consistent and uniform result, enabling artists to achieve the desired level of refinement with ease.

By using glass edge polishing machines, artisans can smooth out the rough edges caused by cutting or shaping the glass during the blow molding process. The machines utilize advanced abrasive materials, such as diamond-coated belts or wheels, to gradually grind away any irregularities, leaving a pristine edge. This level of precision allows for clean and seamless joints when assembling multiple glass pieces, enhancing the durability and aesthetics of the final product.

Versatility in Design and Customization

Glassblowers are renowned for their ability to create unique and customized designs. Glass edge polishing machines further contribute to artistic freedom by enabling the creation of intricate patterns and shapes. These machines come with a variety of attachments and tools that allow artists to experiment with different edging styles, beveled edges, or decorative accents.

Additionally, glass edge polishing machines can be programmed to follow specific patterns or designs, providing even more customization options. This versatility empowers glassblowers to push the boundaries of their creativity and produce one-of-a-kind pieces that captivate both the eye and the touch.

Improving Efficiency and Time Management

Hand polishing glass edges is a labor-intensive task, often requiring considerable time and effort. Glass edge polishing machines streamline this process by automating it, significantly reducing production time. Artists can focus their energy on other aspects of glassblowing, such as shaping the glass or adding intricate details, without compromising the quality of the final polish.

Moreover, these machines are designed to handle various glass thicknesses and sizes, ensuring that the polishing process remains efficient regardless of the dimensions of the glass object. This capability not only saves time but also allows glassblowers to optimize their production workflow and handle larger orders or more complex projects.

Safety and Sustainability Considerations

Glass edge polishing machines prioritize safety measures, providing a controlled and secure environment for the glassblower. These machines are equipped with safety sensors and mechanisms that prevent accidents and injuries, minimizing the risk associated with manual polishing methods.

Furthermore, glass edge polishing machines contribute to sustainability efforts in the art of glassblowing. The automated process minimizes material waste by efficiently utilizing the glass, reducing the need for excessive trimming or excessive reshaping. Additionally, these machines have energy-saving features, ensuring that the polishing process consumes minimal power and leaves a smaller carbon footprint.

Conclusion:

Glassblowing is an art form that continues to thrive, thanks to technological advancements such as glass edge polishing machines. These machines not only enhance the precision and uniformity of glass edges but also provide limitless design possibilities, improve efficiency, and prioritize safety and sustainability. With the aid of these versatile machines, glassblowers can unleash their creativity and usher in a new era of extraordinary glass creations.