The Advantages of Glass Edge Polishing Machines for Architectural Glass

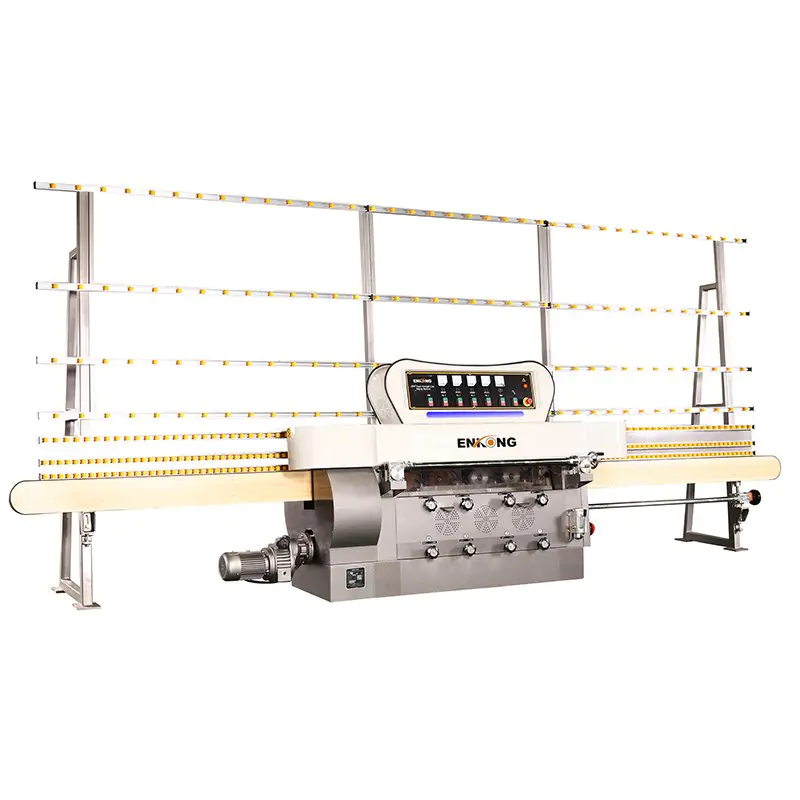

Glass edge polishing machines are the secret behind achieving flawless architectural glass installations. These machines offer numerous advantages that make them an essential tool for professionals in the glass industry. Whether you are working on large-scale architectural projects or smaller residential installations, glass edge polishing machines can revolutionize your workflow and deliver outstanding results.

In this article, we will explore the various advantages of using glass edge polishing machines. From maximizing efficiency and precision to enhancing the overall aesthetic appeal, these machines are a game-changer for architects, designers, and glass manufacturers. Let's delve into the world of glass edge polishing machines and uncover their remarkable benefits.

1. Unparalleled Precision: Taking glass finishing to new heights

Precision is paramount when it comes to architectural glass installations. Glass edge polishing machines are designed to ensure unparalleled precision in every facet of their operation. These machines utilize advanced technology and innovative techniques to deliver smooth and precisely finished edges. The result is glass with impeccably polished edges, free from any imperfections or unevenness.

The high level of precision offered by glass edge polishing machines eliminates the need for manual grinding and polishing, which can be time-consuming and prone to human errors. With these machines, every part of the glass edge receives equal attention, resulting in perfectly even edges that meet the strictest industry standards.

2. Enhanced Efficiency: Boosting productivity and reducing costs

Efficiency is a key factor in any manufacturing process, and glass edge polishing is no exception. Glass edge polishing machines are designed to streamline the polishing process, significantly boosting productivity and reducing costs. These machines automate various tasks, eliminating the need for manual labor and reducing the risk of errors.

By automating the polishing process, glass edge polishing machines allow professionals to complete tasks in a fraction of the time it would take using traditional methods. This increased efficiency translates to significant cost savings for glass manufacturers and contractors, as it reduces labor expenses and maximizes output without compromising on quality.

3. Versatility: Catering to diverse architectural glass requirements

Architectural glass comes in various shapes, sizes, and thicknesses, making versatility a crucial factor when choosing a glass edge polishing machine. These machines are highly versatile and can cater to a wide range of glass specifications, ensuring a seamless integration into any architectural project.

Whether you are working with curved glass, beveled glass, or multi-layered glass, glass edge polishing machines can adapt to the specific requirements of each project. The ability to handle different glass thicknesses and profiles makes these machines a valuable asset for professionals seeking versatility in their glass edge polishing process.

4. Superior Quality: Elevating the visual impact of architectural glass

Architectural glass is not only a functional component but also a design element that contributes to the overall aesthetic appeal of a structure. The quality of the glass edges plays a significant role in enhancing the visual impact of architectural glass installations. Glass edge polishing machines excel in delivering superior quality finishes that elevate the appearance of the glass.

These machines eliminate any roughness, chipping, or unevenness that can detract from the beauty of the glass. The consistent and flawless edges achieved by the machines contribute to a sleek, refined look that impresses clients and adds value to architectural projects. The superior quality provided by glass edge polishing machines ensures that the glass edges meet the high standards expected in the industry.

5. Increased Durability: Strengthening glass for long-lasting performance

In addition to aesthetic appeal, glass edge polishing machines also contribute to the durability and longevity of architectural glass. By removing any sharp edges or microcracks, these machines strengthen the glass and reduce the risk of breakage or damage. This is especially important for structural glass applications, where strength and durability are paramount.

The polishing process performed by glass edge polishing machines smooths out the edges, creating a more resilient glass surface. This increased durability ensures that the glass can withstand environmental factors, such as temperature changes and mechanical stress, without compromising its structural integrity. The enhanced durability provided by glass edge polishing machines gives architects, designers, and clients peace of mind, knowing that the glass will stand the test of time.

In conclusion, glass edge polishing machines offer a multitude of advantages that revolutionize the glass industry. The unparalleled precision, enhanced efficiency, versatility, superior quality, and increased durability provided by these machines make them an indispensable tool for professionals in the architectural glass sector. By investing in glass edge polishing machines, architects, designers, and glass manufacturers can streamline their workflow, achieve impeccable finishes, and deliver outstanding glass installations that exceed client expectations. Embrace the power of glass edge polishing machines, and unlock a new level of excellence in architectural glass.