Space-Saving Solutions: Small Glass Edge Polishing Machines for Compact Workspaces

Space-Saving Solutions: Small Glass Edge Polishing Machines for Compact Workspaces

Glass edge polishing is a critical process in the manufacturing and finishing of glass products. Achieving smooth and polished edges is essential for enhancing the aesthetic appeal and safety of glass items. However, working with glass can be challenging, particularly when space is limited. In this article, we will explore the benefits of small glass edge polishing machines designed specifically for compact workspaces. These innovative solutions offer efficiency, convenience, and high-quality results.

1. Introduction to Small Glass Edge Polishing Machines

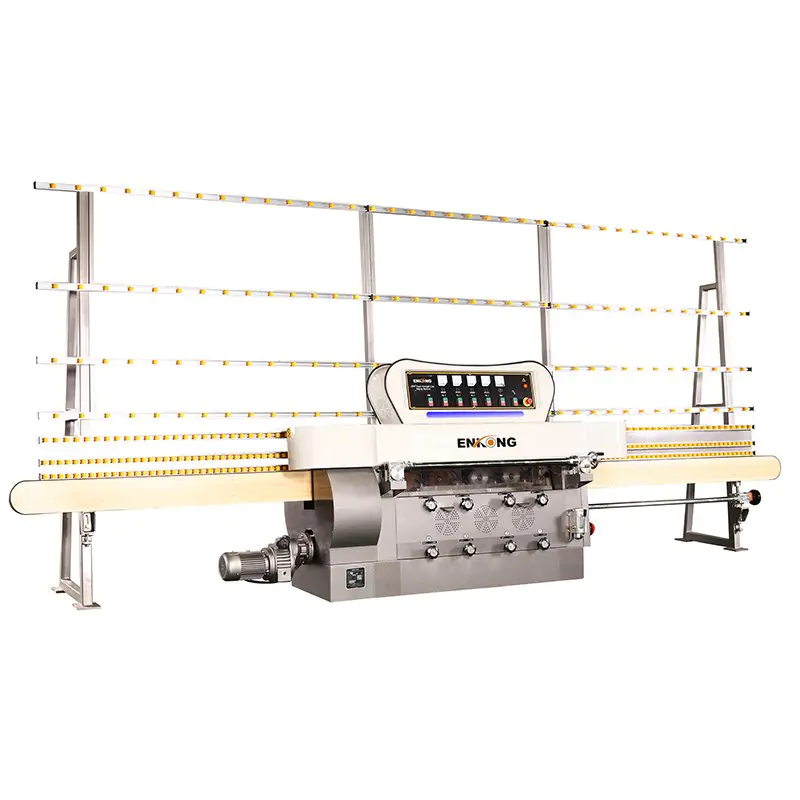

Glass edge polishing machines are specialized equipment used to refine and polish the edges of glass panels, mirrors, and other glass products. Traditionally, these machines have been bulky and required large workspaces to accommodate their size. However, recent advancements in technology have led to the development of small glass edge polishing machines that are specifically designed for compact workspaces.

2. Space-Saving Design for Compact Workspaces

The primary advantage of small glass edge polishing machines is their space-saving design. These machines are compact and lightweight, allowing them to be easily accommodated in small workshops or studios. With their smaller footprint, they provide glass artisans and manufacturers with the flexibility to set up their workstations in limited spaces without compromising on the quality of the final product.

3. Enhanced Portability and Flexibility

Small glass edge polishing machines offer enhanced portability and flexibility compared to their larger counterparts. Their lightweight design allows for easy transportation, making them ideal for on-site glass installations or mobile glass workshops. With these portable machines, glass craftsmen can seamlessly bring their polishing capabilities to customers' locations, eliminating the need for costly transportation or delays.

4. Advanced Features and Functionality

Despite their smaller size, small glass edge polishing machines are equipped with advanced features and functionalities. These machines are designed to provide precise control and accurate polishing, ensuring the highest quality finish on glass edges. They often come with adjustable speed settings, which allow users to tailor the polishing process according to the specific glass thickness and desired edge finish.

5. Efficient and Time-Saving Operations

Small glass edge polishing machines are optimized for efficiency and time-saving operations. Their smaller size enables faster setup and minimal downtime, resulting in increased productivity. Additionally, these machines typically incorporate automated functions, such as automated feeding and polishing, reducing the manual labor involved. This not only streamlines the polishing process but also ensures consistent results across multiple glass pieces.

6. Safety Measures and User-Friendly Interfaces

Safety is of utmost importance when working with glass, and small glass edge polishing machines prioritize user protection. These machines are equipped with safety features such as guards and emergency stop buttons to minimize the risk of accidents. Furthermore, they feature user-friendly interfaces with intuitive controls, allowing operators with varying levels of experience to operate the machine safely and efficiently.

7. Versatility and Compatibility with Various Glass Types

Small glass edge polishing machines are designed to be versatile and compatible with a wide range of glass types. Whether it's standard glass, tempered glass, laminated glass, or even intricate glass shapes, these machines can handle the variety effortlessly. This versatility expands the possibilities for glass artisans and manufacturers, enabling them to create custom-designed products with polished edges.

8. Maintenance and Longevity

Maintenance is crucial for the longevity and optimal performance of any machinery. Small glass edge polishing machines are designed with easy maintenance in mind. They often feature accessible components and easy-to-clean surfaces, simplifying the upkeep process. Regular maintenance not only extends the lifespan of the machine but also ensures consistent polishing quality over time.

9. Conclusion

In conclusion, small glass edge polishing machines bring innovative solutions to the limited workspace challenges faced by glass artisans and manufacturers. Their space-saving design, enhanced portability, advanced features, and user-friendly interfaces make them indispensable tools for achieving high-quality results. With the ability to execute efficient operations across various glass types, these machines empower glass craftsmen to unlock their full creative potential while optimizing time, resources, and workspace utilization.

Guangdong Enkong Machinery Co.,Ltd. is a gaint manufacturer of glass machine, which is one of the most outstanding product produced from us.

We want to continue to organize Enkong to make it more efficient and profitable so that both, our clients and our employees can get more out of their time.

Enkong provides a number of glass processing machines designed to handle glass machine manufacturer.

The global market is estimated to reach a value of almost glass processing machines in the next decade. have a robust position in the glass machine manufacturer market because of its proven high potency in glass processing machines.