Integrating Glass Machinery into Your Workflow: Tips for Success

Glass machinery plays a crucial role in various industries, ranging from construction to automotive. However, integrating this equipment into your workflow can be a daunting task. With the right strategies and knowledge, you can successfully incorporate glass machinery into your operations and ensure optimal efficiency and productivity. In this article, we will explore five essential tips that will guide you towards a successful integration.

Understanding Your Workflow Requirements

Before diving into the integration process, it is vital to have a clear understanding of your workflow requirements. Analyze your existing processes and identify areas where glass machinery can streamline operations and provide value. Consider the specific tasks and applications where this equipment will be utilized and assess the volume and frequency of usage. By comprehending your workflow requirements, you can make informed decisions throughout the integration process.

Take the time to consult with your team members who are directly involved in the workflow. Their insights and expertise will be valuable in identifying potential challenges and opportunities for improvement. Engage in open and transparent communication to ensure that everyone is on the same page regarding the integration process.

Investing in Quality Machinery

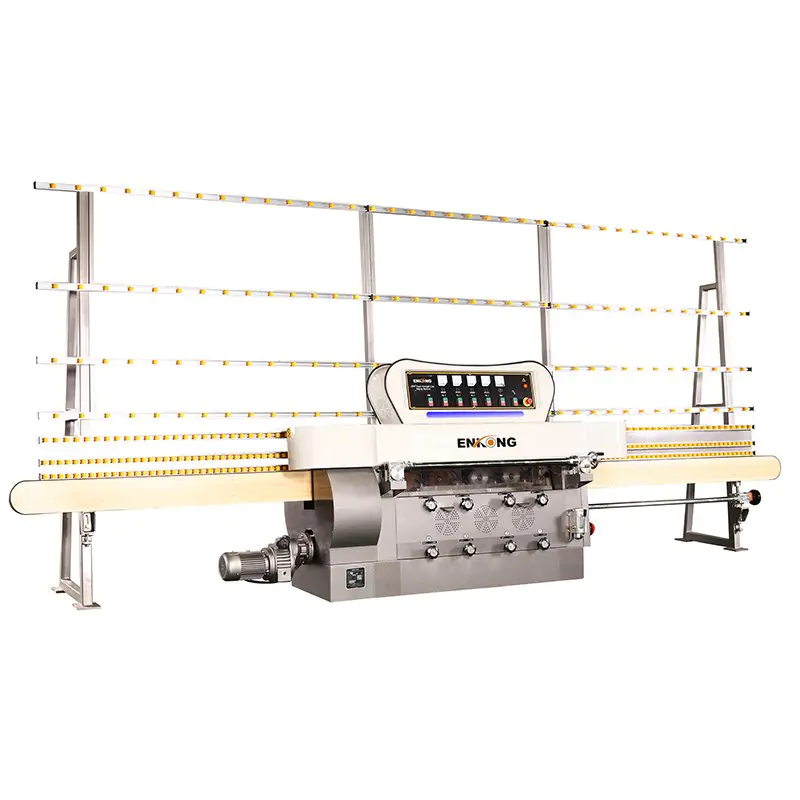

When it comes to integrating glass machinery into your workflow, investing in high-quality equipment is crucial. Quality machinery will not only provide optimal performance but also ensure the longevity and reliability of the equipment. Research reputable manufacturers and suppliers that specialize in glass machinery and have a track record of delivering reliable products.

Consider the specific features and specifications that align with your workflow requirements. For example, if you require precision cutting, look for machinery that offers advanced cutting technologies and accurate measurement systems. Evaluate the durability and maintenance requirements of the equipment to ensure it can withstand the demands of your workflow.

While cost is an important consideration, it should not be the sole determining factor. Remember that investing in quality machinery will yield long-term benefits and minimize downtime and repair costs. Consider the equipment's warranty and after-sales support to further safeguard your investment.

Training and Education

Integrating glass machinery into your workflow will invariably require training and education for your team members. The complexity of these machines necessitates a thorough understanding of their operation, safety protocols, and maintenance requirements. Without proper training, the risk of accidents, errors, and inefficient use of the equipment increases significantly.

Identify training programs or workshops conducted by the equipment manufacturer or trusted industry organizations. These programs often provide comprehensive training on the operation, maintenance, and troubleshooting of glass machinery. Ensure that all relevant team members receive the necessary training and certification to use the machinery safely and effectively.

In addition to initial training, consider ongoing education and refresher courses to keep your team members up-to-date with the latest advancements in glass machinery technology. This will enable your workforce to harness the full potential of the equipment and maximize productivity.

Creating a Safe and Ergonomic Environment

The integration of glass machinery requires the creation of a safe and ergonomic environment. Safety should always be a top priority when working with machinery that involves sharp glass, heavy components, and moving parts. Conduct a thorough risk assessment of your workspace and implement appropriate safety measures.

Ensure that all team members have access to personal protective equipment (PPE) such as gloves, goggles, and safety shoes. Clearly mark hazardous areas and provide ample signage to remind employees of safety protocols. Regularly inspect machinery for any signs of wear or damage and address any maintenance or repair concerns promptly.

Ergonomics is another crucial aspect to consider when integrating glass machinery. Repetitive tasks and awkward postures can lead to musculoskeletal disorders. Evaluate the layout of your workspace and make necessary adjustments to promote ergonomic working conditions. Consider the installation of height-adjustable workstations, anti-fatigue mats, and proper lighting to minimize strain and enhance productivity.

Monitoring Performance and Continuous Improvement

Once the glass machinery is integrated into your workflow, it is essential to monitor its performance and identify areas for continuous improvement. Regularly analyze data and metrics to evaluate the efficiency and effectiveness of the equipment. This can be done through the utilization of software systems or manual tracking methods.

Identify key performance indicators (KPIs) that align with your workflow goals and track them consistently. These KPIs could include production output, machine downtime, maintenance costs, and product quality. By monitoring performance, you can identify bottlenecks, potential issues, and areas for improvement.

Engage your team in regular feedback sessions to gather their observations and suggestions for enhancing the integration process. Encourage an environment of continuous improvement and innovation. Empower your employees to propose creative solutions and actively involve them in problem-solving initiatives.

Conclusion

Integrating glass machinery into your workflow can be a transformative step towards enhancing efficiency and productivity. By understanding your workflow requirements, investing in quality machinery, providing training and education, creating a safe and ergonomic environment, and monitoring performance, you can ensure a successful integration process.

Remember that the integration process is an ongoing journey that requires constant evaluation and adjustment. Embrace change and embrace the potential of glass machinery to revolutionize your operations. With the right strategies and a proactive approach, you can optimize your workflow and achieve new heights of success.

Getting doesn't have to be expensive, time-consuming, or difficult. It all comes down to the right method and a glass processing machines glass machine in place.

We are an experienced supplier of and have gained good reputaion among global customers. With a wide range of in offer, we can customize according to your requirement. Send us your enquiry at Enkong Glass Machinery.

Latest technology and manufacturing equipment has improved the quality of glass machine.

Guangdong Enkong Machinery Co.,Ltd. can promise that glass machine is one of the best products sold in the worldwide market at present.