Integrating Glass Machinery into Your Production Line: Tips for Success

Introduction:

In today's rapidly advancing industrial landscape, integrating state-of-the-art machinery into your production line is crucial for staying competitive. This rings particularly true for sectors like glass manufacturing, where precision and efficiency are paramount. By seamlessly integrating glass machinery into your production line, you can enhance productivity, quality, and overall operational effectiveness. This article provides valuable tips and insights on successfully integrating glass machinery, ensuring your business thrives in this dynamic industry.

The Importance of Integrating Glass Machinery

Integrating glass machinery into your production line offers a myriad of benefits that can significantly impact your business. Firstly, it allows you to automate various processes, reducing the reliance on manual labor. By doing so, you can eliminate human errors, enhance precision, and maximize throughput. Additionally, advanced glass machinery often boasts cutting-edge technologies that enable superior quality control. This enables you to consistently produce flawless glass products, bolstering customer satisfaction and increasing your market reputation.

Furthermore, integrating glass machinery enhances efficiency and reduces production lead times. Modern equipment is designed to optimize operational processes, minimize downtime, and streamline workflows. This, in turn, allows you to meet customer demands more efficiently, potentially leading to increased sales and revenue. Moreover, by automating repetitive tasks, you can free up your workforce, enabling them to focus on more complex and value-added activities.

Tips for Successful Integration

Successfully integrating glass machinery into your production line requires careful planning and execution. Here are some essential tips to help you navigate the process:

1. Conduct a Thorough Needs Assessment

Before making any purchasing decisions, it's crucial to conduct a detailed needs assessment. Analyze your production requirements, specific processes that need improvement, and the desired output. Identify bottlenecks, pain points, and areas where automation could bring the most significant benefits. By understanding your needs thoroughly, you can select the right machinery that aligns with your goals and objectives.

2. Collaborate with Industry Experts

When integrating new glass machinery, collaborating with industry experts can prove invaluable. Seek out the expertise of manufacturers, suppliers, or consultants who specialize in glass manufacturing. They possess the knowledge and experience to guide you towards the most suitable equipment for your specific requirements. Additionally, these experts can provide support throughout the implementation process, ensuring seamless integration and minimizing disruptions to your production line.

3. Ensure Compatibility and Scalability

Compatibility with existing equipment is a critical factor in successful integration. Assess whether the new glass machinery is compatible with your current production line and whether it can seamlessly integrate with your existing systems. Consider the scalability of the machinery as well, as you want to invest in equipment that can accommodate future growth and evolving needs.

4. Train Your Workforce

Investing in comprehensive training for your workforce is key to maximize the benefits of integrated glass machinery. Ensure that your employees are well-versed in operating the new equipment, maintenance protocols, troubleshooting procedures, and safety precautions. This will empower your workforce to harness the full potential of the machinery and make the most of the enhanced capabilities it offers.

5. Embrace Continuous Improvement

Integration is an ongoing process, and there will always be room for improvement. Encourage a culture of continuous improvement within your organization to identify areas where optimization is possible. Regularly review data, performance metrics, and customer feedback to fine-tune your production processes. Embrace emerging technologies and advancements in the glass manufacturing industry to stay ahead of the competition and keep your production line efficient and cutting-edge.

Conclusion

Successfully integrating glass machinery into your production line is a strategic decision that can revolutionize your business. By automating processes, enhancing efficiency, and ensuring superior product quality, you are poised to thrive in the competitive glass manufacturing industry. Remember to conduct a thorough needs assessment, collaborate with industry experts, ensure compatibility and scalability, train your workforce, and embrace continuous improvement. By following these tips, you can achieve seamless integration, setting your business on the path to sustained success.

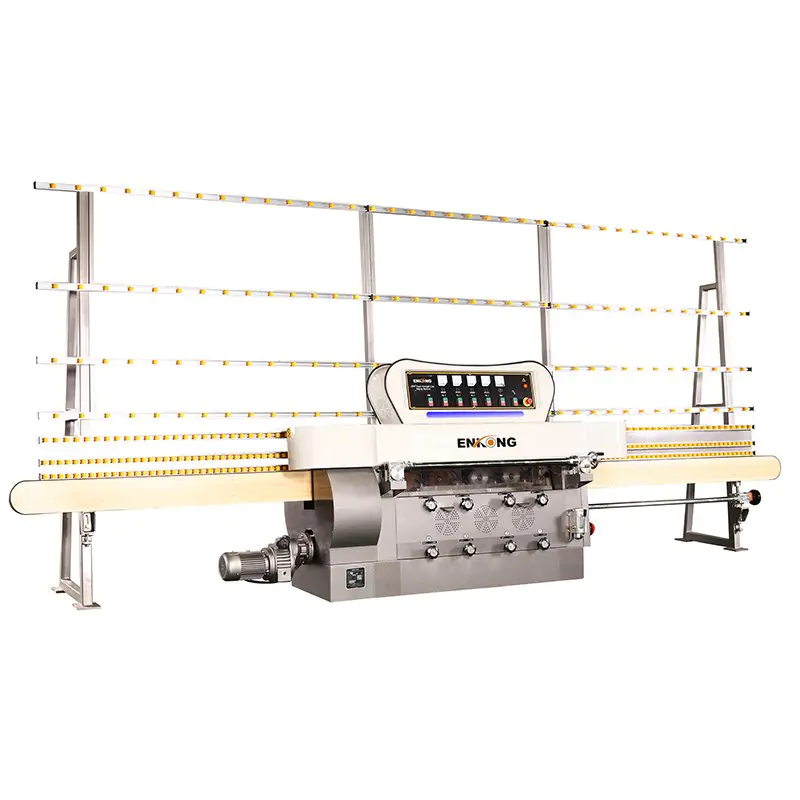

This is an internationally recognized standard which acts as a form of guarantee that everything Guangdong Enkong Machinery Co.,Ltd. does is managed to the highest quality standards.

Interested in the that create such effect? Come to Enkong Glass Machinery to see some items.

Turn to Guangdong Enkong Machinery Co.,Ltd. if you are looking for premier glass machine manufacturer solution, affordable packages, and quality glass machine products! We produce wide series of high quality, first-class , and provide professional glass machine services at great prices.

glass machine offers the opportunity for improved manufacturing and product’s data collection, as well as direct feedback, enabling companies to better understand their consumer base and respond accordingly.