Glass Mitering Machines: Tips for Ensuring Accurate and Clean Cuts

Introduction:

Glass mitering machines are essential tools for achieving precise and clean cuts in glass fabrication. Whether you are working on architectural glass, furniture, or other glass projects, having the right mitering machine and employing the correct techniques can make a substantial difference in the quality of your cuts. This article will provide you with invaluable tips and insights on how to ensure accurate and clean cuts when using glass mitering machines.

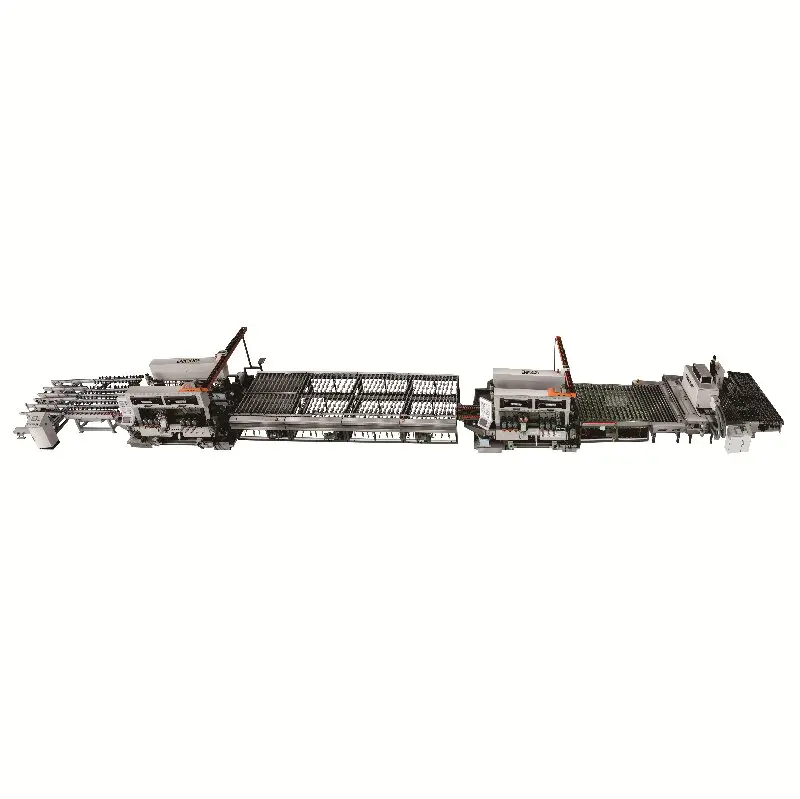

The Importance of Choosing the Right Glass Mitering Machine

Choosing the right glass mitering machine is the first step towards achieving accurate and clean cuts. There are various factors to consider when selecting a suitable machine for your needs.

One crucial aspect to look for is the machine's cutting precision. Precision is vital, as it determines the quality of the final result. Look for a mitering machine that features a robust and reliable cutting mechanism, such as a diamond or carbide blade, to ensure clean and precise cuts every time.

Additionally, consider the machine's flexibility and adjustability. A good mitering machine should offer adjustable angles and be able to handle different glass thicknesses. This versatility allows you to tackle a wide range of projects and ensures optimal precision and accuracy.

Another important consideration is the machine's overall build quality. Look for a sturdy and durable construction, as this will directly impact the machine's performance and longevity. Investing in a high-quality glass mitering machine is essential for achieving consistent and reliable results.

Preparation: Proper Cleaning and Measurement

Before operating the glass mitering machine, it is crucial to prepare the glass properly. Cleaning the glass surface is essential to ensure accurate measurements and prevent any debris from interfering with the cutting process.

Start by thoroughly cleaning the glass surface with a specialized glass cleaner. Remove any dust, fingerprints, or other contaminants that may affect the accuracy of your measurements. Use a lint-free cloth to avoid leaving particles on the glass surface.

After cleaning, take precise measurements of the glass dimensions. Accurate measurements are paramount to achieving clean and seamless mitered cuts. Use a high-quality tape measure or a digital measuring device to ensure precision. It is advisable to double-check your measurements before proceeding to the cutting stage.

Securing the Glass: Use of Clamps and Supports

To ensure stability and prevent glass slippage during the mitering process, it is crucial to secure the glass in place. The use of clamps and supports is highly recommended to maintain the glass's position and prevent any shifting or movement that may compromise the accuracy of the cuts.

Use sturdy clamps that provide adequate pressure to hold the glass firmly in place without damaging its surface. Position the clamps strategically to ensure stability during the cutting process. In addition to the clamps, consider the use of supports, such as foam pads or wooden blocks, to reinforce and balance the glass throughout the mitering procedure.

Choosing the Right Cutting Technique: Wet or Dry Cutting

Glass mitering machines offer two primary cutting techniques: wet and dry cutting. Each technique has its advantages and considerations, depending on the specific project requirements.

Wet cutting involves the use of a continuous water supply during the cutting process. Water acts as a coolant, reducing heat generation and preventing the glass from cracking or chipping. Wet cutting also helps to minimize dust and debris, resulting in cleaner and smoother cuts. However, the use of water can be messy and requires proper containment and disposal systems.

Dry cutting, on the other hand, involves cutting the glass without water. This technique is suitable for projects where water is not feasible or when dealing with thicker glass. Dry cutting produces faster results and avoids the hassle of water management. However, it generates more dust, necessitating the use of appropriate dust control measures.

Carefully assess the requirements of your project and consider the advantages and challenges of both wet and dry cutting techniques before selecting the most appropriate method for your glass mitering machine.

Proper Blade Maintenance: Ensuring Longevity and Precision

Keeping your glass mitering machine's blades in optimal condition is crucial for achieving accurate and clean cuts consistently. Dull or damaged blades can lead to poor cutting performance, chipping, or even breakage of the glass during the mitering process. Therefore, proper blade maintenance is essential.

Regularly inspect the blades for any signs of wear or damage. Replace blades as needed to avoid compromising the quality of your cuts. When replacing blades, ensure they are properly installed and tightened to prevent any wobbling or instability during operation.

Additionally, regularly lubricate the blade mechanism according to the manufacturer's instructions. Lubrication helps reduce friction, heat generation, and blade wear, leading to improved cutting performance and longevity.

Furthermore, follow proper blade cleaning procedures after each use. Remove any debris, glass particles, or residue that may accumulate on the blade surface. This ensures that the blades remain clean and sharp, resulting in cleaner and more precise cuts.

Conclusion

Achieving accurate and clean cuts when using glass mitering machines requires attention to detail, proper preparation, and the right techniques. From the initial selection of the mitering machine to the preparation of the glass and the cutting process itself, each step plays a crucial role in ensuring the final result meets your expectations.

By choosing a high-quality glass mitering machine, preparing the glass properly, securing it correctly, selecting the appropriate cutting technique, and maintaining your blades, you can consistently achieve precise and clean cuts in your glass fabrication projects.

Remember, practice makes perfect. With time and experience, you will become adept at using glass mitering machines and produce flawless and professional-looking cuts. So, start implementing these tips and elevate the quality of your glasswork to new heights.

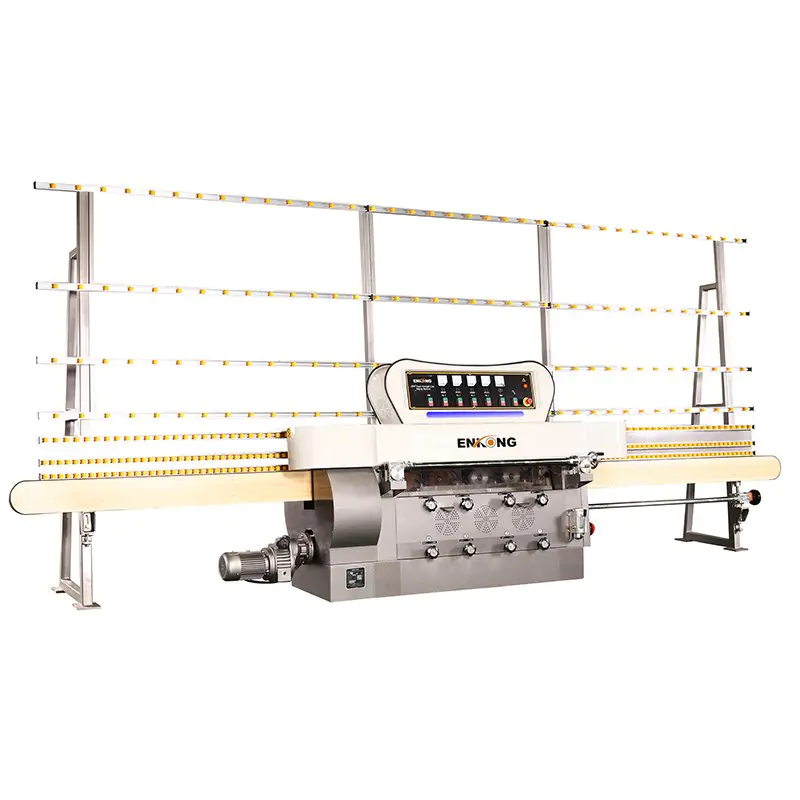

Professional glass machine manufacturer also understand that when you're working with glass processing machines product, it's important to understand that quality of glass machine always matters.

Looking for a company to handle your glass machine glass machine manufacturer? Visit Enkong Glass Machinery today for more information.

Enkong focuses on three key elements—process, people, and technology—the authors found that people of two seemingly opposite cultures are able to work together in a project-based environment to complement each other and reap mutual benefits for a win-win result.

Many of the glass machine listed here can be purchased for less money, but in general we recommend paying a slightly higher price for significantly improved performance. These are our top choices and their recommended configurations.