Glass Grinding and Polishing Equipment: Safety Precautions and Best Practices

Introduction:

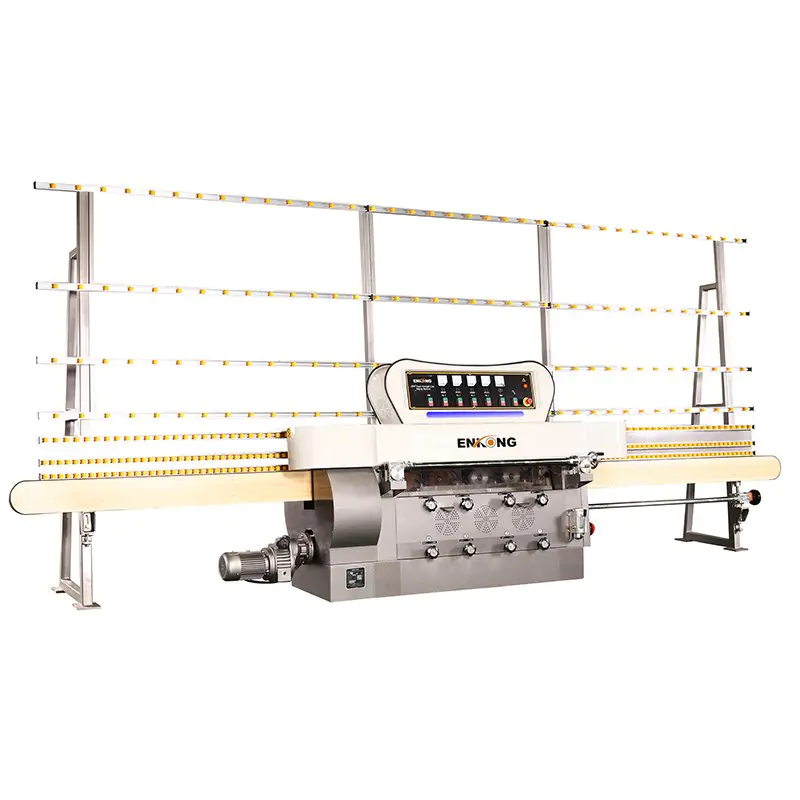

Glass grinding and polishing equipment are essential tools used in various industries such as construction, automotive, and electronics. These machines help achieve smooth and polished glass surfaces, enhancing their visual appeal and functionality. However, working with glass and using such equipment can be potentially hazardous if proper safety precautions and best practices are not followed. This article aims to provide a comprehensive guide on the safety measures and best practices to ensure a secure working environment and achieve optimal results when using glass grinding and polishing equipment.

Safety Gear and Personal Protection Equipment (PPE)

Safety gear and personal protection equipment (PPE) are crucial when operating glass grinding and polishing equipment. They act as a shield against potential hazards, such as flying glass shards and dust particles. Here are some essential items to consider:

Eye Protection:

Wearing safety glasses with side shields or goggles is paramount to protect the eyes from debris and glass fragments. These devices provide a barrier against potential eye injuries, ensuring the safety of the operator.

Respiratory Protection:

Depending on the type of grinding or polishing being performed, dust and airborne particles may be generated. In these situations, a respirator or a dust mask with appropriate filtration is necessary to prevent the inhalation of harmful particles. It is essential to choose the correct type of respiratory protection based on the application and level of exposure.

Hand and Arm Protection:

When handling glass sheets or utilizing grinding and polishing equipment, the hands and arms are prone to cuts and abrasions. To mitigate these risks, wearing cut-resistant gloves or Kevlar sleeves is highly recommended. These protective measures provide an additional layer of defense while maintaining dexterity and manual control.

Foot Protection:

As with any industrial setting, wearing suitable footwear is crucial. Safety shoes or boots with steel toe caps and slip-resistant soles protect against heavy objects, accidental slips, and potential electrical hazards in some equipment.

Equipment Setup and Workspace

Creating a safe and optimized workspace is essential to ensure efficiency and minimize potential accidents or injuries. Consider the following factors when setting up the equipment and workspace:

Proper Equipment Installation:

Before operating glass grinding and polishing equipment, it is vital to ensure that the machines are correctly installed and securely anchored to prevent vibrations during use. Loose or unstable equipment can pose risks to both the operator and the surrounding environment.

Work Area Organization:

Maintaining an organized work area leads to better workflow and reduces the chances of accidents. Remove any unnecessary items or clutter that may hinder movement or cause tripping hazards. Keep the workspace clean and free from any obstacles that could interfere with the operation of the equipment.

Workspace Ventilation:

Glass grinding and polishing processes often generate dust and fine particles, which can be hazardous when inhaled. Adequate ventilation is necessary to remove these contaminants from the workspace. Consider installing local exhaust ventilation systems or ensuring that the area is well-ventilated to maintain a safe and healthy working environment.

Proper Lighting:

Good lighting is crucial to ensure visibility and accuracy when working with glass grinding and polishing equipment. Insufficient lighting can lead to errors in judgment and increase the likelihood of accidents. Use proper lighting fixtures or task lights to illuminate the workspace adequately.

Safe Operating Procedures

Following safe operating procedures is essential to prevent accidents and injuries while using glass grinding and polishing equipment. Here are some key best practices to consider:

Equipment Inspection:

Before starting any grinding or polishing task, thoroughly inspect the equipment for any signs of damage or malfunction. Pay close attention to power cords, switches, and guards. If any faults or defects are identified, repairs or maintenance should be performed by qualified personnel before proceeding.

Securely Clamp the Glass:

Always securely clamp the glass being worked on to prevent it from slipping or moving during the grinding or polishing process. This ensures better control over the equipment and reduces the risk of accidents caused by uncontrolled movements.

Use the Correct Grinding and Polishing Discs:

Choosing the appropriate discs for the task at hand is crucial. Different types of glass and finishing requirements may require specific discs with varying abrasiveness and grit sizes. Using the wrong discs can result in inefficient grinding or polishing and may compromise the safety of the operator.

Proper Tool Rest and Work Support:

Ensure that the tool rests and work supports provided by the equipment are adjusted correctly to hold the glass securely. Improper positioning can lead to glass breakage or the equipment malfunctioning, posing potential risks to the operator.

Limit Excessive Force:

Applying excessive force during the grinding or polishing process can lead to glass breakage or equipment damage. Let the equipment's weight and design do the work. Apply gentle and steady pressure, allowing the abrasives to perform effectively without unnecessary strain.

Maintenance and Cleaning

Regular maintenance and cleaning of glass grinding and polishing equipment are essential for their optimal performance and longevity. Consider the following aspects:

Scheduled Inspection and Servicing:

Establish a routine maintenance schedule to inspect and service the equipment as recommended by the manufacturer. This ensures that any potential issues are addressed promptly, reducing the chances of unexpected failures or accidents.

Proper Storage:

When not in use, store the equipment in a dry and secure location, away from extreme temperatures and corrosive materials. Follow the manufacturer's recommendations for storage to prevent damage and maintain the integrity of the machine.

Cleaning Procedures:

Regularly clean the equipment to remove accumulated debris, dirt, and abrasive materials. Use appropriate cleaning agents and tools recommended by the manufacturer, taking care to protect sensitive components from moisture or chemical damage.

Summary:

When using glass grinding and polishing equipment, prioritizing safety precautions and best practices is essential to minimize accidents, maintain a secure working environment, and achieve the desired results. By adhering to the recommended safety gear, creating an optimized workspace, following safe operating procedures, and maintaining equipment properly, operators can ensure their well-being and maximize the efficiency and longevity of the equipment. Remember, working with glass can be a precise and rewarding process, but safety should always be the top priority.