Glass Beveling vs. Polishing: Which Technique is More Cost-Effective?

Introduction:

Glass is a versatile material that is widely used in various industries, from construction to automotive. Its transparency, durability, and aesthetic appeal make it a popular choice. However, to achieve the desired look and functionality, glass often requires additional processes such as beveling or polishing. These techniques enhance the visual appeal, smoothness, and safety of glass surfaces. When it comes to cost-effectiveness, choosing the right technique can be crucial. In this article, we will explore the differences between glass beveling and polishing and evaluate their cost effectiveness, helping you make an informed decision for your specific glass needs.

The Process of Glass Beveling

Glass beveling is a process that involves creating a sloping surface known as a bevel on the edge of the glass. This bevel is typically achieved by grinding the edge at an angle, resulting in a chamfered edge. Beveling serves both functional and aesthetic purposes. Functionally, beveling reduces the risk of glass breakage by eliminating sharp edges. Aesthetically, it adds a decorative touch to the glass, enhancing its overall visual appeal.

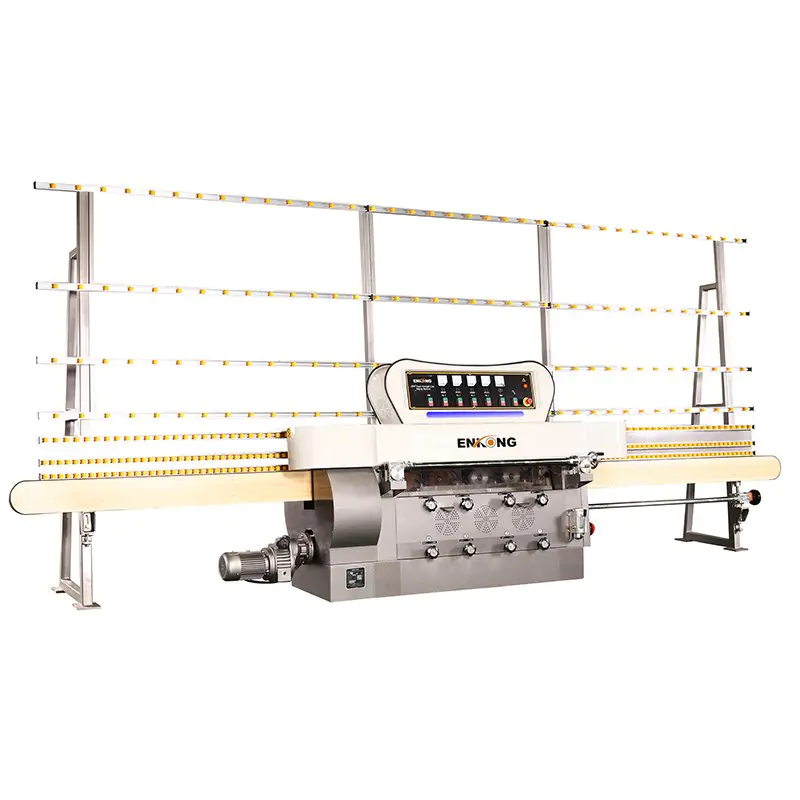

During the beveling process, the glass is first cut to the desired size and shape. Then, specialized machinery is used to grind the edges at the desired bevel angle. This machinery utilizes diamond wheels to remove the glass material gradually, resulting in a smooth and polished beveled edge. The angle of the bevel can be customized to achieve different design effects, ranging from a subtle chamfer to a more pronounced bevel.

Glass beveling is mainly used in applications where visual appeal is a crucial factor, such as decorative glass, mirrors, furniture, and architectural elements. It adds a touch of elegance and sophistication to the finished product, making it a popular choice in various industries.

The Process of Glass Polishing

Glass polishing, on the other hand, focuses on refining the surface of the glass to achieve smoothness and clarity. The polishing process involves removing surface imperfections, such as scratches and marks, resulting in a clear and flawless glass surface. Polishing is often performed after the glass has been cut, shaped, or fabricated to the desired size and shape.

The process of glass polishing typically involves using special polishing compounds, pads, and machinery. The glass surface is carefully polished with a rotating pad and the polishing compound, which acts as an abrasive, gradually smoothing out imperfections. This process is repeated until the desired level of clarity and smoothness is achieved.

Polishing is commonly used in applications where visual clarity and smoothness are critical, such as display cases, optical lenses, and glassware. It is also utilized in the automotive industry to restore the clarity of glass windshields by removing scratches and haze.

Factors Affecting Cost-Effectiveness

When evaluating the cost-effectiveness of glass beveling and polishing techniques, several factors come into play. It is essential to consider these factors to determine which technique is best suited for your specific requirements and budget.

1. Design Complexity:

The complexity of the desired design is a significant factor affecting the cost-effectiveness of glass beveling and polishing. Beveling, especially intricate and custom designs, can be more time-consuming and require specialized machinery and skilled labor. As a result, the cost of beveling may be higher compared to a simpler design. On the other hand, the cost of glass polishing is generally more dependent on the size and surface area rather than the complexity of the design.

2. Material Thickness:

The thickness of the glass also plays a role in determining the cost-effectiveness of beveling or polishing. Beveling is more commonly performed on thicker glass, where the beveled edge adds a substantial visual impact. Thicker glass requires more material removal during beveling, resulting in higher costs compared to polishing. Polishing, on the other hand, is typically performed on thinner glass where surface imperfections are more visible, making it a cost-effective solution for achieving desired clarity and smoothness.

3. Volume and Batch Size:

The volume and batch size of the glass components also affect the cost-effectiveness of beveling and polishing. Beveling, being a more intricate process, may require longer setup times and specialized tooling for each component. This can result in higher costs for small volume or batch production. In contrast, polishing can be more economical for larger volumes or batch sizes, as the process can be streamlined, reducing setup costs and maximizing efficiency.

4. Time Constraints:

Time constraints can also impact the cost-effectiveness of glass beveling versus polishing. Beveling, being a more time-consuming process, may result in longer production lead times compared to polishing. If time is a critical factor, such as in time-sensitive projects or urgent orders, the cost-effectiveness of polishing may outweigh that of beveling due to quicker turnaround times.

5. Desired End Result:

Ultimately, the desired end result and the specific application play a crucial role in determining the cost-effectiveness of glass beveling or polishing. Beveling adds a decorative and elegant touch to glass, making it ideal for applications where visual aesthetics are paramount. Polishing, on the other hand, focuses on achieving clarity and smoothness, making it suitable for applications that require high transparency and surface quality.

Summary:

In conclusion, both glass beveling and polishing are valuable techniques for enhancing the visual appeal, safety, and surface quality of glass. The cost-effectiveness of each technique depends on several factors, including design complexity, material thickness, volume, batch size, time constraints, and the desired end result. When considering which technique to choose, it is crucial to evaluate these factors and align them with your specific requirements and budget.

Glass beveling is an ideal choice for applications requiring decorative elegance, such as decorative glass, mirrors, furniture, and architectural elements. The customization options and the added safety benefits make it a worthwhile investment. On the other hand, glass polishing is more cost-effective for achieving visual clarity and smoothness, making it suitable for display cases, optical lenses, and glassware.

Ultimately, the choice between glass beveling and polishing depends on your priorities, budget, and the specific requirements of your project. Consulting with a glass professional can provide invaluable insights and help you make an informed decision to achieve the desired results within your budget constraints.

The manufacture marketing game of glass machine is changing with each innovation, and businesses of all products need to be ready to pounce.

Super quality are in offer at Enkong Glass Machinery, welcome to visit us.

Utilizing high technology to manufacture products can afford a fully experience to customers by using glass machine.

It is never too late to have a new mindset and to get things moving in the right direction. Choose Guangdong Enkong Machinery Co.,Ltd. to be your quality provider.