Factors to Consider When Pricing a Glass Beveling Machine

Introduction:

Glass beveling machines play a crucial role in the production and finishing of glass products, providing the perfect beveled edge that enhances the aesthetic appeal and functionality of glass panels. When it comes to pricing a glass beveling machine, there are several factors that need to be taken into consideration. These factors help determine the overall cost and value of the machine, ensuring that you make an informed decision. In this article, we will delve into the essential factors that should be considered when pricing a glass beveling machine, ensuring that you get the best value for your investment.

Machinery Capacity and Speed

The capacity and speed of a glass beveling machine are pivotal aspects to consider when pricing the equipment. The capacity of the machine refers to its ability to handle various sizes and thicknesses of glass panels. Machines with higher capacities can accommodate a wide range of glass sizes, offering greater versatility in production. Manufacturers may indicate the maximum size and thickness of glass that a machine can handle, making it easier for buyers to assess the machine's suitability for their needs.

Speed is another vital aspect to consider as it directly impacts productivity and efficiency. The speed of glass beveling machines can vary significantly, with some machines offering faster processing times than others. Faster machines are beneficial for high-volume glass processing operations as they can significantly reduce production time and increase overall output. However, it's essential to strike a balance between speed and precision to ensure that the machine can deliver high-quality beveled edges consistently.

Machine Design and Construction

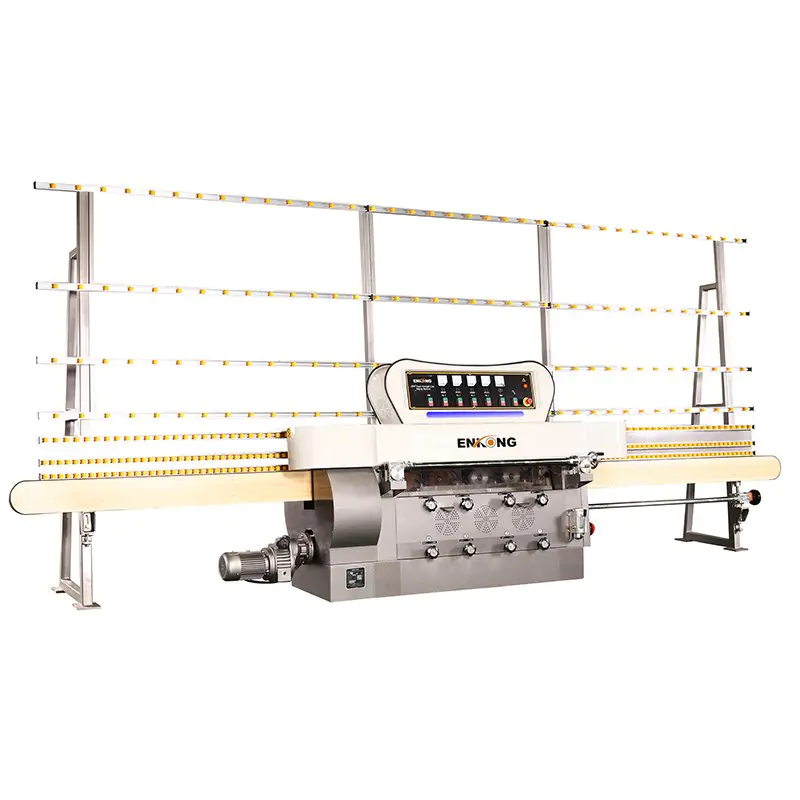

The design and construction of a glass beveling machine greatly influence its pricing. A robust and well-built machine typically commands a higher price due to its durability, reliability, and longevity. It is crucial to choose a machine constructed using high-quality materials that can withstand the demands of continuous operation in a glass processing facility.

The design of the machine should also be considered, as it plays a significant role in its ease of use and maintenance. A well-designed machine will have user-friendly features, intuitive controls, and accessible maintenance points, making it easier for operators to operate and maintain the equipment. Machines with complex designs may require additional training and maintenance expertise, leading to increased costs in the long run.

Beveling Precision and Quality

The precision and quality of the beveled edges produced by a glass beveling machine are vital factors to consider when determining its price. The accuracy of the machine's beveling mechanism directly affects the quality of the finished product. High-precision machines employ advanced technology and precise calibration systems to ensure consistent and accurate beveling results. These machines may come at a higher price point due to the sophistication of their design and manufacturing.

When assessing the beveling quality, factors such as edge smoothness, angle consistency, and surface finish must be taken into account. Buyers should thoroughly examine the finished beveled edges produced by the machine to ensure that they meet the desired standards. Opting for a machine that offers superior beveling quality may incur additional costs initially, but it can lead to higher customer satisfaction and improved competitiveness in the long term.

Machine Versatility and Flexibility

In modern glass processing facilities, versatility and flexibility are highly valued characteristics in beveling machines. The ability to perform various beveling profiles, such as straight, curved, and custom shapes, is essential to meet the diverse demands of customers. A machine that offers multiple beveling options allows glass manufacturers to cater to different design preferences and stay ahead in the market.

Moreover, machines that can be easily adjusted and reconfigured for different glass thicknesses and beveling angles provide greater flexibility in production. This adaptability reduces the need for investing in multiple machines and enables manufacturers to optimize production processes and reduce downtime between product changeovers. While versatile and flexible machines may come at a slightly higher price, their ability to enhance production efficiency and accommodate changing market demands justifies the investment.

After-Sales Support and Warranty

After-sales support and warranty coverage are crucial factors to consider when pricing a glass beveling machine. Investing in high-quality machinery is not only about the initial purchase but also about the long-term support and service provided by the manufacturer. It is essential to choose a supplier that offers comprehensive after-sales support, including training programs, technical assistance, and readily available spare parts.

Warranty coverage is another critical aspect to consider. A machine with an extended warranty period indicates the manufacturer's confidence in its reliability and durability. A longer warranty not only offers peace of mind but also helps in reducing potential maintenance and repair costs during the early stages of machine ownership.

Conclusion:

Pricing a glass beveling machine requires careful evaluation of various factors that contribute to its overall cost and value. Machinery capacity, speed, design, beveling precision, versatility, and after-sales support are all influential factors that should be thoroughly considered. By taking these factors into account, you can make an informed decision and choose a glass beveling machine that meets your production requirements while offering optimal efficiency and long-term value. Remember, investing in a high-quality machine may require a higher initial cost, but it can lead to improved productivity, enhanced product quality, and increased customer satisfaction in the long run.

Every day of the year, there is some city or town in the world that is changing over to for glass processing machines.

Guangdong Enkong Machinery Co.,Ltd. is one of leading glass machine manufacturer glass machine distributors. You can order , and accessories for your need. Meeting your business need is always our top priority. Any of your enquiry is warmly welcomed.

In terms of glass machine, why is it different than other production? How does it fit a true need or desire for your requires? Is it simple to use? Make life easier?

glass machine has its grasp on oversees market also and has a very good repute.