Exploring the Types of Glass Machines and Their Functions

Introduction:

Glass machines have revolutionized the manufacturing industry, making the production of various glass products faster, more efficient, and of superior quality. These machines range from simple tools to complex systems that perform specific functions in the glass manufacturing process. In this article, we will explore the different types of glass machines and delve into their functions, highlighting their significance in the industry.

Types of Glass Machines and Their Functions:

1. Cutting Machines:

Cutting is one of the fundamental processes in glass manufacturing, and cutting machines play a crucial role in achieving precise, accurate cuts. These machines use various methods to cut glass, including diamond-tipped blades, abrasive wheels, and lasers. Diamond blade cutting machines are commonly used for straight line cutting, while abrasive wheel cutting machines are suitable for shapes and curves. Laser cutting machines offer high precision and are ideal for intricate and complex designs.

Cutting machines are equipped with advanced features such as computer numerical control (CNC) systems, which enable precise programming and automation, resulting in consistent and accurate cuts. With the ability to cut various thicknesses of glass, these machines are versatile and widely used in the production of glass windows, doors, mirrors, and decorative glass products.

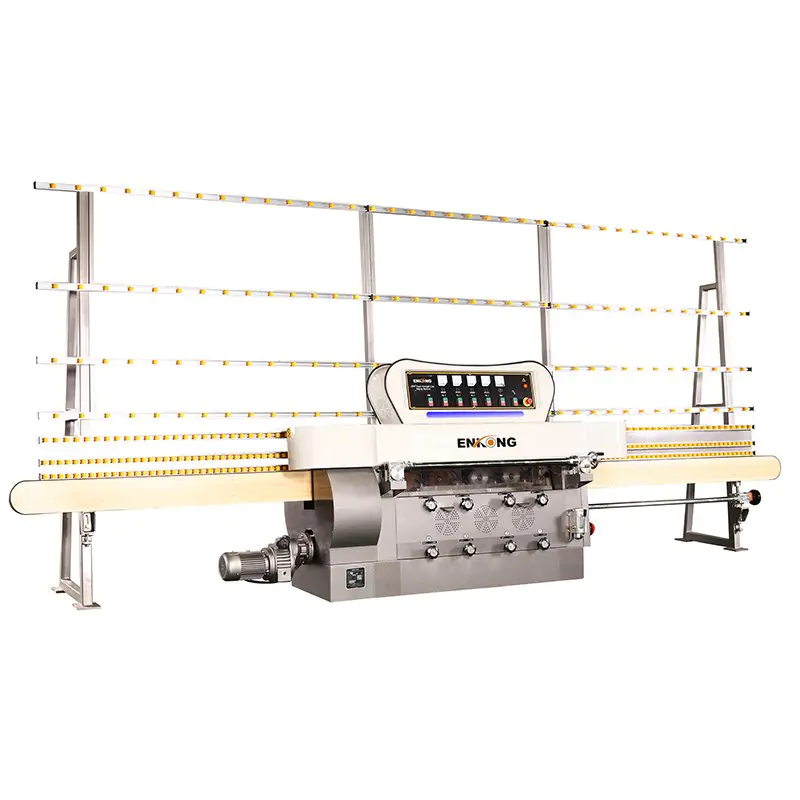

2. Edging and Polishing Machines:

After the glass has been cut, it often requires additional processing to achieve a smooth and polished finish. Edging and polishing machines are specifically designed for this purpose. These machines utilize grinding wheels and polishing belts to remove any rough edges or imperfections and create a polished and aesthetically pleasing surface.

Edging machines are used to shape the glass edges, while polishing machines refine the edges and provide a glossy finish. The process involves the use of water, coolants, and diamond abrasives, ensuring the highest quality results. These machines are particularly essential in the production of glass furniture, tabletops, glass shelves, and architectural glass, as they enhance the safety and visual appeal of the final product.

3. Tempering and Heat Strengthening Machines:

Tempered glass is widely used in applications that require increased strength and safety. Tempering machines subject the glass to intense heat followed by rapid cooling, creating a state of surface and edge compression. This process significantly enhances the strength and impact resistance of the glass, making it more durable and less likely to break into sharp shards when shattered.

Heat strengthening machines, on the other hand, provide a milder version of the tempering process, resulting in glass with improved strength while retaining its aesthetic characteristics. These machines are commonly used in the production of automotive glass, shower doors, glass facades, and other safety glass applications.

4. Laminating Machines:

Laminated glass is a type of safety glass that consists of two or more layers of glass bonded together with an interlayer of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). Laminating machines are used to create this composite material by subjecting the glass layers and interlayer to heat and pressure, ensuring a strong bond.

This type of glass offers several benefits, including improved sound insulation, enhanced security, and resistance to ultraviolet radiation. Furthermore, in the event of breakage, the interlayer holds the shattered glass together, preventing it from scattering, and reducing the risk of injury. Laminating machines find extensive use in the production of automotive windshields, safety glass partitions, and bullet-resistant glass.

5. Insulating Glass Production Lines:

Insulating glass, also known as double or triple glazing, consists of two or more glass panes separated by a sealed air or gas-filled space. These glass units provide improved thermal insulation, reduced noise transmission, and condensation resistance. Insulating glass production lines are used to manufacture these units efficiently and to ensure their long-term durability.

These production lines involve multiple stages, including glass washing, drying, spacer application, glass assembling, and gas filling, followed by the sealing process. Advanced insulating glass production lines incorporate automation, ensuring precise alignment, gas filling control, and continuous production. The resulting insulating glass units are widely used in the construction industry for windows, curtain walls, and energy-efficient building envelopes.

Conclusion:

Glass machines play an integral role in the manufacturing industry, offering efficiency, precision, and enhanced product quality. The various types of machines discussed in this article, including cutting machines, edging and polishing machines, tempering and heat strengthening machines, laminating machines, and insulating glass production lines, cater to different stages of the glass manufacturing process.

These machines have revolutionized the glass industry, enabling the production of a wide range of glass products, including windows, doors, mirrors, furniture, automotive glass, safety glass, and architectural glass. Investing in the right glass machine can significantly improve productivity, reduce production time, minimize waste, and ultimately contribute to the growth and success of glass manufacturers worldwide.

are important in ensuring glass machine manufacturer, and the machine is utilised by everyone from glass processing machines to glass machine manufacturer.

For more advice on tips, please visit our website Enkong Glass Machinery. Do not hesitate to contact us if you are interested.

Overall, glass machine may be a great way for manufacturers to expand their use of technology, but the price could present a significant hurdle for some businesses.

glass processing machines problems are nothing new, almost every one of us have to go through them at some point of our lives and some of us never get rid of them. with the development of glass machine manufacturer technology, now provides a perfect cure for that.

Producing with varied technical skills, glass machine can be used in a wide range of applications as glass processing machines.