Enhancing Efficiency and Productivity with Modern Glass Processing Machines

Introduction:

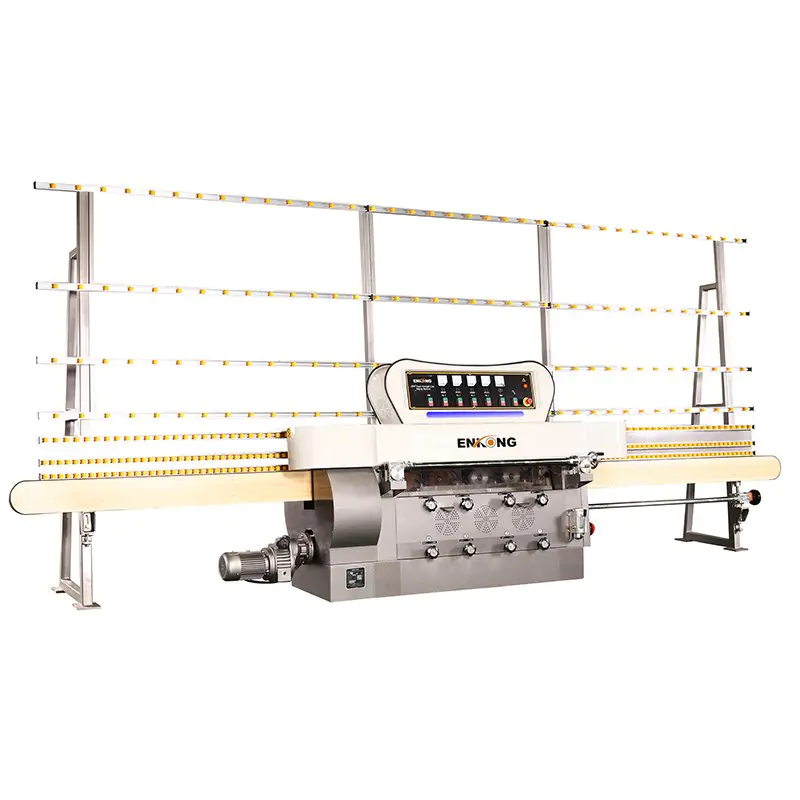

Glass processing is an essential aspect of various industries, including construction, automotive, furniture, and more. The efficiency and productivity of glass processing play a crucial role in meeting the growing demands of these industries. Technology advancements have led to the development of modern glass processing machines that have revolutionized the industry. These machines offer a wide range of features and capabilities to enhance productivity, precision, and cost-effectiveness. In this article, we will explore how modern glass processing machines have significantly improved efficiency and productivity in different applications.

The Benefits of Modern Glass Processing Machines

Modern glass processing machines offer numerous benefits that contribute to enhancing efficiency and productivity. Let's delve into some of these advantages:

Improved Precision and Accuracy:

Accuracy is of utmost importance in glass processing, as even the slightest error can lead to costly mistakes. Modern glass processing machines utilize advanced technologies such as computer numerical control (CNC) systems, which enable precise and accurate glass cutting, shaping, and edging. These machines use high-resolution sensors and intelligent algorithms to ensure the desired measurements are achieved consistently. With increased precision, manufacturers can reduce rework, minimize wastage, and deliver high-quality glass products to their customers.

Increased Speed and Throughput:

Efficiency and productivity go hand in hand with the speed at which glass processing machines operate. Modern machines are designed to handle glass processing tasks at significantly higher speeds compared to traditional methods. This increase in speed allows manufacturers to complete projects in shorter time frames, enabling them to take on more orders and meet tight deadlines. As a result, businesses can maximize their output, improve customer satisfaction, and gain a competitive edge in the market.

Versatility and Customization:

Another key advantage of modern glass processing machines is their versatility and ability to handle a wide range of glass types, shapes, and sizes. Whether it's straight-line cutting, beveling, drilling, or engraving, these machines offer customizable options to meet diverse customer requirements. Advanced software interfaces and programming capabilities allow manufacturers to design unique glass products with intricate patterns and shapes without compromising on efficiency. This flexibility enables businesses to cater to the growing demand for customized glass solutions in different industries.

Reduced Labor and Operational Costs:

By automating various glass processing tasks, modern machines significantly reduce the need for extensive manual labor, resulting in cost savings for businesses. These machines can perform multiple operations simultaneously, eliminating the need for separate machines and labor for each task. Moreover, automated processes minimize human errors, reducing the chances of product damage and rework. The decreased reliance on manual labor not only saves costs but also ensures consistent quality and improves overall efficiency.

Enhanced Safety and Worker Well-being:

Glass processing can be a hazardous task, exposing workers to risks such as cuts, eye injuries, and repetitive strain injuries. Modern glass processing machines prioritize safety by incorporating safety features such as enclosed cutting areas, laser sensors, and automatic shut-off mechanisms. These features minimize the chances of accidents and injuries during glass processing operations, ensuring the well-being of workers. By creating a safer work environment, businesses can boost employee morale, reduce absenteeism, and improve overall productivity.

The Applications of Modern Glass Processing Machines

Modern glass processing machines find applications in various industries. Let's explore some of these industries and the ways in which these machines enhance efficiency and productivity:

Construction Industry:

Glass plays a crucial role in modern architectural designs, providing aesthetic appeal and energy-efficient solutions. Modern glass processing machines enable precise cutting, shaping, and drilling of glass panels, facilitating seamless installation in buildings. Moreover, these machines can create complex patterns and designs on glass surfaces, adding artistic elements to architectural projects. The speed and accuracy of modern glass processing machines enable construction companies to complete projects on time, contributing to increased efficiency and customer satisfaction.

Automotive Industry:

The automotive industry extensively relies on glass for windshields, windows, and other components. Modern glass processing machines allow manufacturers to cut and shape glass with high precision and efficiency, meeting the demands of automotive production lines. These machines can also perform complex glass processing tasks such as laminating and tempering, ensuring the durability and safety of automotive glass products. By incorporating modern glass processing machines, automotive manufacturers can streamline their production processes and improve the overall quality of their vehicles.

Furniture Industry:

The furniture industry often incorporates glass elements in tables, shelves, cabinets, and decorative pieces. Modern glass processing machines offer precise cutting, shaping, and edging of glass panels, enabling furniture manufacturers to create custom designs with polished edges and intricate details. These machines also facilitate the creation of curved glass pieces, expanding the design possibilities for furniture makers. By utilizing modern glass processing machines, the furniture industry can produce high-quality glass furniture efficiently, meeting customer expectations and design requirements.

Electronics Industry:

The electronics industry relies on glass for displays, touchscreens, and other components. The use of modern glass processing machines ensures the production of glass components with accurate measurements and fine details. These machines can handle thin glass sheets with utmost precision, ensuring the integrity and functionality of electronic devices. With the ability to process glass quickly and accurately, manufacturers in the electronics industry can meet the demands of growing consumer electronics markets and enhance production efficiency.

Summary

Modern glass processing machines have revolutionized the industry by significantly enhancing efficiency and productivity. The benefits these machines offer, such as improved precision, increased speed, versatility, reduced labor costs, and enhanced safety, empower various industries to optimize their glass processing operations. Whether it's the construction, automotive, furniture, or electronics industry, modern glass processing machines provide the tools necessary to meet customer requirements accurately and efficiently. As technology continues to advance, we can expect further innovations in glass processing machines, leading to even greater efficiency and productivity in the future.