Customizing Glass Machinery: Tailoring Solutions to Your Needs

Introduction:

Glass manufacturing is a complex industry that requires advanced machinery and equipment to meet the specific requirements of each individual customer. As the demand for customized glass products continues to grow, the need for tailor-made solutions becomes increasingly important. Customizing glass machinery allows manufacturers to optimize their production processes, enhance efficiency, and deliver high-quality products that meet the unique specifications and demands of their customers. In this article, we will explore the benefits of customizing glass machinery, the different areas where customization is possible, and the key factors to consider when implementing customized solutions.

The Benefits of Customizing Glass Machinery

Customizing glass machinery offers a range of benefits that contribute to the overall success and productivity of a glass manufacturing business. Here are some of the key advantages:

1. Enhanced Efficiency and Productivity:

When machinery is customized to match specific production requirements, it can significantly improve efficiency and productivity. By eliminating unnecessary steps or implementing automation processes, manufacturers can streamline their operations, reduce downtime, and increase overall output. This ensures that the production process is optimized to meet customer demands in a timely manner.

2. Improved Quality and Precision:

Customized glass machinery is designed to deliver precise and accurate results, ensuring that each product meets the required quality standards. By tailoring the machinery to specific production needs, manufacturers can achieve better control over variables such as glass thickness, size, shape, and finishing. This leads to superior quality products that meet or exceed customer expectations.

3. Cost Optimization:

While the initial investment for customizing glass machinery may be higher, it can result in long-term cost savings. By eliminating unnecessary features or processes, customized machinery reduces waste, minimizes energy consumption, and lowers maintenance and repair costs. It also allows businesses to optimize their production capacity, resulting in higher revenue generation.

4. Flexibility and Adaptability:

One of the significant advantages of customizing glass machinery is the ability to adapt to changing market trends and customer demands. With customized solutions, manufacturers can easily modify or upgrade machinery as per the evolving needs of their customers. This flexibility ensures that businesses can keep up with technological advancements and stay competitive in the market.

5. Better Customer Satisfaction:

When glass products are customized to meet specific requirements, it enhances customer satisfaction. Tailoring machinery solutions enables manufacturers to create unique and innovative glass products that fulfill the precise needs and preferences of their clients. This not only strengthens customer relationships but also opens up opportunities for repeat business and referrals.

Areas of Customization in Glass Machinery

Customization in glass machinery can be achieved in various areas, depending on the specific needs of the manufacturer and their customers. Here are some key areas where customization can be implemented:

1. Glass Cutting and Shaping:

One of the fundamental processes in glass manufacturing is cutting and shaping. Customizing machinery in this area allows manufacturers to achieve precision cuts, complex shapes, and intricate designs. Advanced technologies such as CNC (Computer Numerical Control) can be incorporated to automate and improve cutting accuracy. By tailoring the cutting and shaping processes, manufacturers can create unique and customized glass products that cater to the demands of their customers.

1. Glass Tempering and Annealing:

Tempering and annealing are crucial steps in glass production that enhance the strength and durability of the final product. Customized machinery allows manufacturers to control the tempering and annealing process according to the specific requirements of different glass types and thicknesses. This ensures that the glass achieves the desired characteristics, such as increased resistance to thermal stress or improved safety properties.

1. Glass Lamination and Bonding:

Glass lamination and bonding are techniques used to combine multiple layers of glass or to bond glass with other materials, such as plastics or metals. Customizing machinery in this area enables manufacturers to achieve precise bonding, uniform pressure distribution, and optimal curing conditions. By tailoring the lamination and bonding processes, manufacturers can create laminated glass with specific properties, such as sound insulation, UV protection, or bullet resistance.

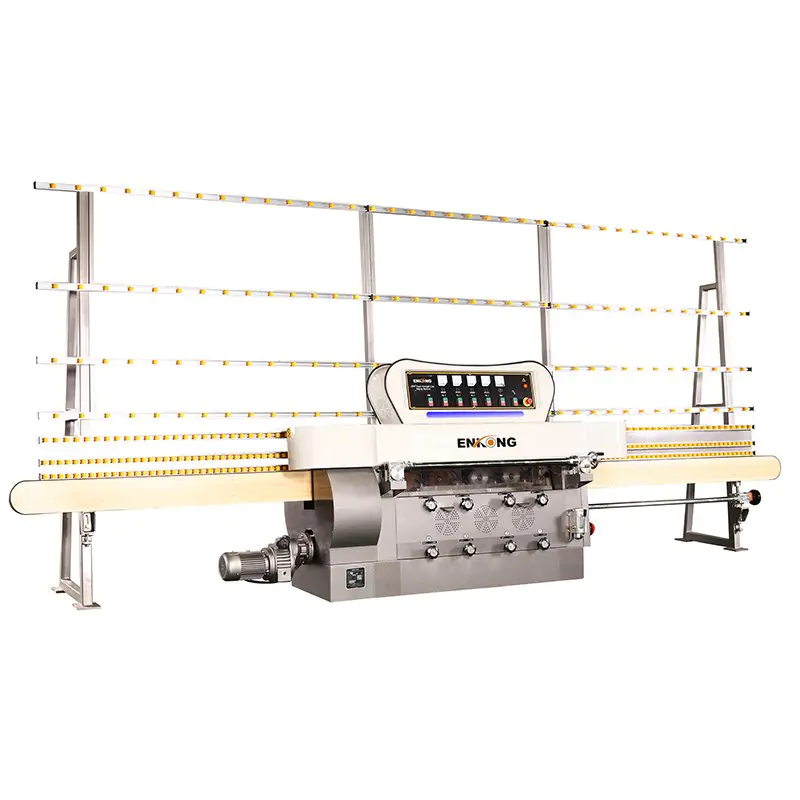

1. Glass Edging and Polishing:

The edging and polishing of glass are essential to achieve a smooth and finished appearance. Customizing machinery in this area allows manufacturers to customize the edge shape, size, and finishing of the glass. This helps in creating glass products that are aesthetically pleasing, safe, and free from sharp edges or defects. Advanced polishing techniques can be incorporated to achieve high-gloss or textured finishes, giving the glass a unique and personalized touch.

1. Glass Inspection and Quality Control:

Customization in the area of glass inspection and quality control plays a crucial role in ensuring that the final products meet the desired standards. By incorporating advanced inspection technologies such as computer vision systems or automated defect detection, manufacturers can identify and eliminate any flaws or imperfections during the production process. This enhances the overall quality control measures, reduces rejections, and ensures that only superior quality glass products are delivered to the customers.

Implementing Customized Solutions: Key Considerations

Implementing customized solutions in glass machinery requires careful planning and consideration of various factors. Here are some key considerations to keep in mind:

1. Understanding Customer Requirements:

To successfully customize glass machinery, it is essential to have a thorough understanding of customer requirements. This includes factors such as the types of glass products, desired features, production volume, and specific quality standards. By understanding these requirements, manufacturers can customize their machinery to deliver products that precisely meet customer expectations.

2. Collaboration with Experts:

Customizing glass machinery can be a complex process that requires the expertise of professionals in the field. Collaborating with experienced engineers, technicians, and machinery manufacturers can provide valuable insights and guidance throughout the customization process. Their expertise can help identify the right technologies, processes, and equipment needed to achieve the desired results.

3. Budget and Cost Analysis:

Customization in glass machinery involves an investment of both time and resources. It is crucial to conduct a comprehensive cost analysis to assess the feasibility and financial implications of implementing customized solutions. While customization offers long-term benefits, it is essential to balance the initial investment with the expected return on investment (ROI).

4. Training and Skill Development:

Introducing customized machinery into the production process may require employees to acquire new skills or knowledge. Providing adequate training and skill development programs can help the workforce adapt to the changes and operate the machinery effectively. This ensures a smooth transition and maximizes the benefits of customized solutions.

5. Maintenance and Support:

Customized machinery requires regular maintenance and support to ensure optimal performance. It is important to establish a maintenance schedule and partner with machinery manufacturers or suppliers who can provide timely support and spare parts. This helps in minimizing downtime and maintaining the productivity of the manufacturing operations.

Conclusion

Customizing glass machinery offers numerous benefits for manufacturers in the glass industry. By tailoring machinery solutions to meet specific needs, manufacturers can enhance efficiency, improve quality, optimize costs, and ultimately achieve higher customer satisfaction. Customization can be implemented in various areas of glass manufacturing, including cutting, tempering, lamination, edging, and quality control. However, it is crucial to consider factors such as customer requirements, expert collaborations, budget analysis, training, and maintenance to successfully implement customized solutions. By embracing customization, glass manufacturers can stay ahead of the competition and deliver innovative, high-quality glass products that meet the evolving needs of their customers.

The global market was valued at glass processing machines in glass machine manufacturer and is expected to reach a market value of glass processing machines by glass machine manufacturer, with a CAGR of glass processing machines during the forecast period.

Now you can enjoy glass machine manufacturer with Guangdong Enkong Machinery Co.,Ltd.'s latest collection of glass processing machines glass machine products. Do visit now, at Enkong Glass Machinery.

Guangdong Enkong Machinery Co.,Ltd. is a initial company that supports expertise in searching marketing solutions.