Choosing the Right Glass Polishing Machine for Different Glass Thicknesses

Overview of Glass Polishing Machines

Glass polishing machines are essential tools in the glass industry, allowing for efficient and effective finishing of various types of glass surfaces. These machines utilize advanced technologies and abrasive materials to remove scratches, stains, and other imperfections, resulting in a smooth and polished glass surface. However, different glass thicknesses require different polishing machines to achieve the desired results. In this article, we will explore the various types of glass polishing machines available and how to choose the right one for different glass thicknesses.

Why Choosing the Right Glass Polishing Machine Matters

Glass comes in various thicknesses, ranging from thin, delicate glass to thicker, more robust glass. The key to achieving optimal polishing results lies in selecting the appropriate glass polishing machine that effectively addresses the specific requirements of a particular glass thickness. Using a machine with inappropriate specifications for a specific glass thickness can lead to subpar results, including uneven polishing, excess material removal, or insufficient correction of defects. Therefore, it is crucial to understand the different types of glass polishing machines available on the market and their suitability for various glass thicknesses.

The Different Types of Glass Polishing Machines

There are several types of glass polishing machines available, each designed for specific glass thicknesses. Here, we will discuss five main types of glass polishing machines and their applications:

1. Handheld Glass Polishing Machines

Handheld glass polishing machines are versatile tools suitable for small-scale projects or intricate glass surfaces. These machines are typically lightweight and maneuverable, allowing technicians to polish glass surfaces with precision and ease. Handheld glass polishing machines are commonly used for thin glass, such as smartphone screens, camera lenses, or watch faces. They are compact and portable, making them ideal for on-the-go repairs or touch-ups.

When using a handheld glass polishing machine, it is essential to exercise caution and apply the appropriate pressure to prevent damage to the delicate glass. The machine's compact size also limits its power, resulting in longer polishing times for thicker glass surfaces. Therefore, handheld machines are not recommended for polishing thicker glass varieties.

2. Tabletop Glass Polishing Machines

Tabletop glass polishing machines are designed for polishing medium-thickness glass sheets or objects. These machines consist of a flat tabletop surface with an automated polishing mechanism. They offer greater stability and power compared to handheld machines, making them suitable for polishing glass countertops, shelves, or medium-sized glass panels.

Tabletop glass polishing machines generally provide adjustable speed settings, allowing technicians to customize the polishing process according to the glass thickness and desired finish. They often come with interchangeable polishing pads that accommodate different abrasive materials. This versatility enables users to achieve varying levels of smoothness and shine based on the specific glass thickness and imperfections.

3. Vertical Glass Polishing Machines

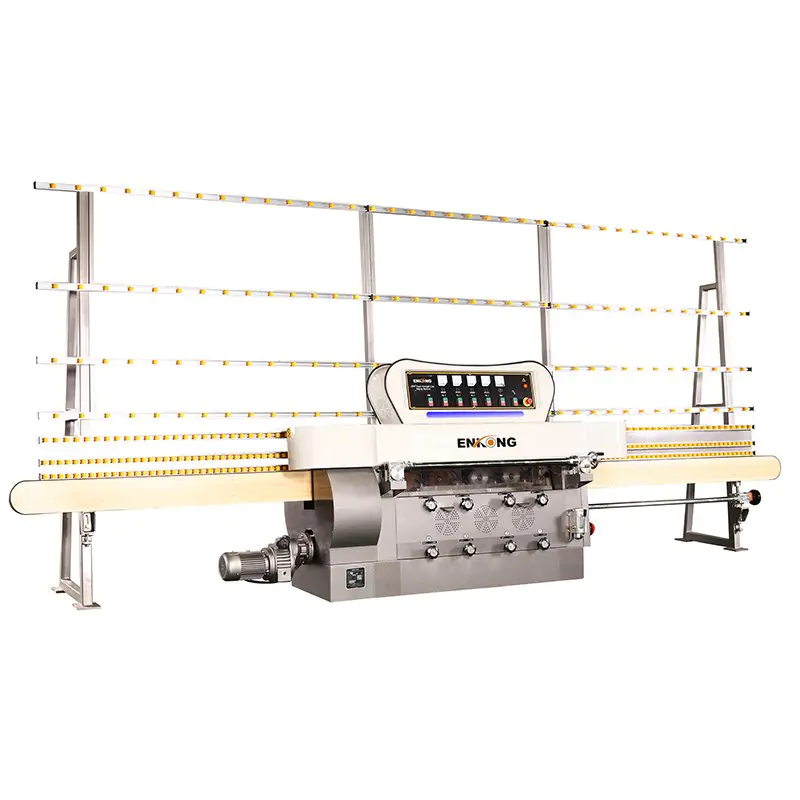

Vertical glass polishing machines are large-scale machines primarily used in industrial settings or for polishing thick glass sheets. These robust machines are specifically designed to handle heavy-duty tasks and can polish glass panels, windows, or architectural glass projects. With their vertical orientation, they can effortlessly accommodate large glass sizes, making them highly efficient for bulk processing.

Vertical glass polishing machines employ powerful motors, abrasive belts, and automated systems to ensure consistent and precise polishing across extensive glass surfaces. Some machines utilize multiple belts or wheels with different grit sizes to achieve the desired smoothness. The adjustable pressure settings cater to different glass thicknesses, enabling optimal polishing results. Due to their size and operational complexity, vertical glass polishing machines are not suitable for small-scale operations or thin glass materials.

4. CNC Glass Polishing Machines

CNC (Computer Numerical Control) glass polishing machines are technologically advanced devices that combine precision and automation. These machines utilize computer programming and control to execute complex polishing patterns, resulting in highly accurate and consistent finishes. CNC glass polishing machines are suitable for a wide range of glass thicknesses, making them versatile options for various glass applications.

The CNC system allows for the creation of intricate polishing profiles, custom shapes, and detailed designs. This feature makes CNC glass polishing machines particularly suitable for architectural glass, decorative glass, or glass with patterns or engravings. CNC machines can efficiently polish both large glass panels and small, delicate glass parts with equal precision and quality.

5. Automated Glass Polishing Systems

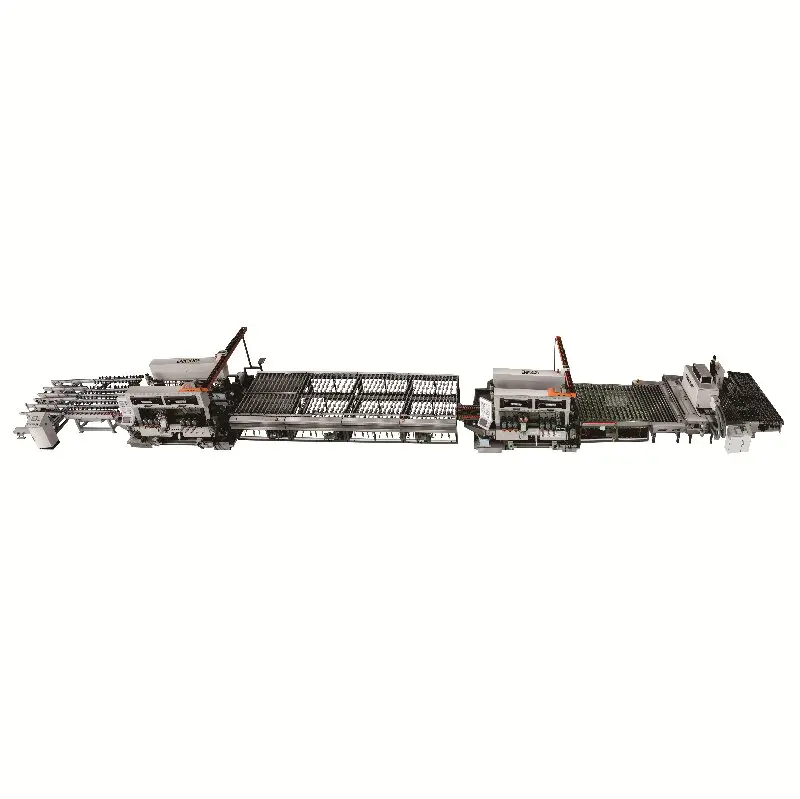

Automated glass polishing systems encompass a wider range of machines and technologies, including robotic polishing systems. These systems are highly automated and often used for large-scale production or high-volume projects. Automated glass polishing systems can be tailored to accommodate different glass thicknesses, making them suitable for various industries, including automotive, electronics, or furniture.

These systems combine precision mechanisms, advanced control systems, and multiple polishing heads to achieve efficient and uniform polishing. They can handle different glass shapes, sizes, and thicknesses, making them ideal for mass production or repetitive tasks. While automated glass polishing systems offer exceptional productivity and quality, their cost and complexity may limit their suitability for smaller glass businesses or projects with irregular shapes.

When selecting a glass polishing machine, it is essential to consider the glass thickness and the specific requirements of the project at hand. Here are some factors to consider when choosing the right glass polishing machine for different glass thicknesses:

1. Size and Weight: The size and weight of the machine should be suitable for the glass thickness and the intended application. For delicate, thin glass, lightweight and portable machines are preferable, while thicker glass requires more heavy-duty and stable machines.

2. Power and Speed: The machine's power and speed settings should align with the specific glass thickness. Thicker glass requires higher power and adjustable speed settings to ensure efficient material removal and polishing.

3. Abrasive Material Compatibility: Different abrasive materials are available for glass polishing, each with its own characteristics and suitable glass thicknesses. Ensure that the chosen machine supports the preferred abrasive material and is compatible with the desired glass thickness.

4. Automation and Precision: Consider the level of automation and precision required for the project. Smaller-scale projects or intricate glass surfaces may benefit from handheld or tabletop machines, while automated systems are more suitable for mass production or complex designs.

5. Budget and Long-term Sustainability: Assess the initial investment cost and the long-term sustainability of the chosen machine. Consider the maintenance requirements, availability of spare parts, and the machine's reliability when selecting a glass polishing machine that fits your budget and operational needs.

Conclusion

Choosing the right glass polishing machine for different glass thicknesses is crucial for achieving optimal polishing results. The variety of glass polishing machines available, from handheld devices to automated systems, provides options for a wide range of glass applications and projects. By considering factors such as size, power, abrasive material compatibility, automation level, and budget, it becomes easier to select a machine that meets the specific requirements of a given glass thickness. Investing in the appropriate glass polishing machine ensures efficient and high-quality polishing, contributing to the overall success of glass-related projects.